Soft-switch hidden-arc welding contrarariant power supply with double closed-loop control

A technology of double closed-loop control and inverter power supply, which is applied in the direction of arc welding equipment, electrical components, manufacturing tools, etc., can solve the problems of high degree of subjectivity of membership function, lower power factor, grid pollution, etc., so as to improve reliability and process adaptation performance, reduce switching loss and electrical stress, and improve working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

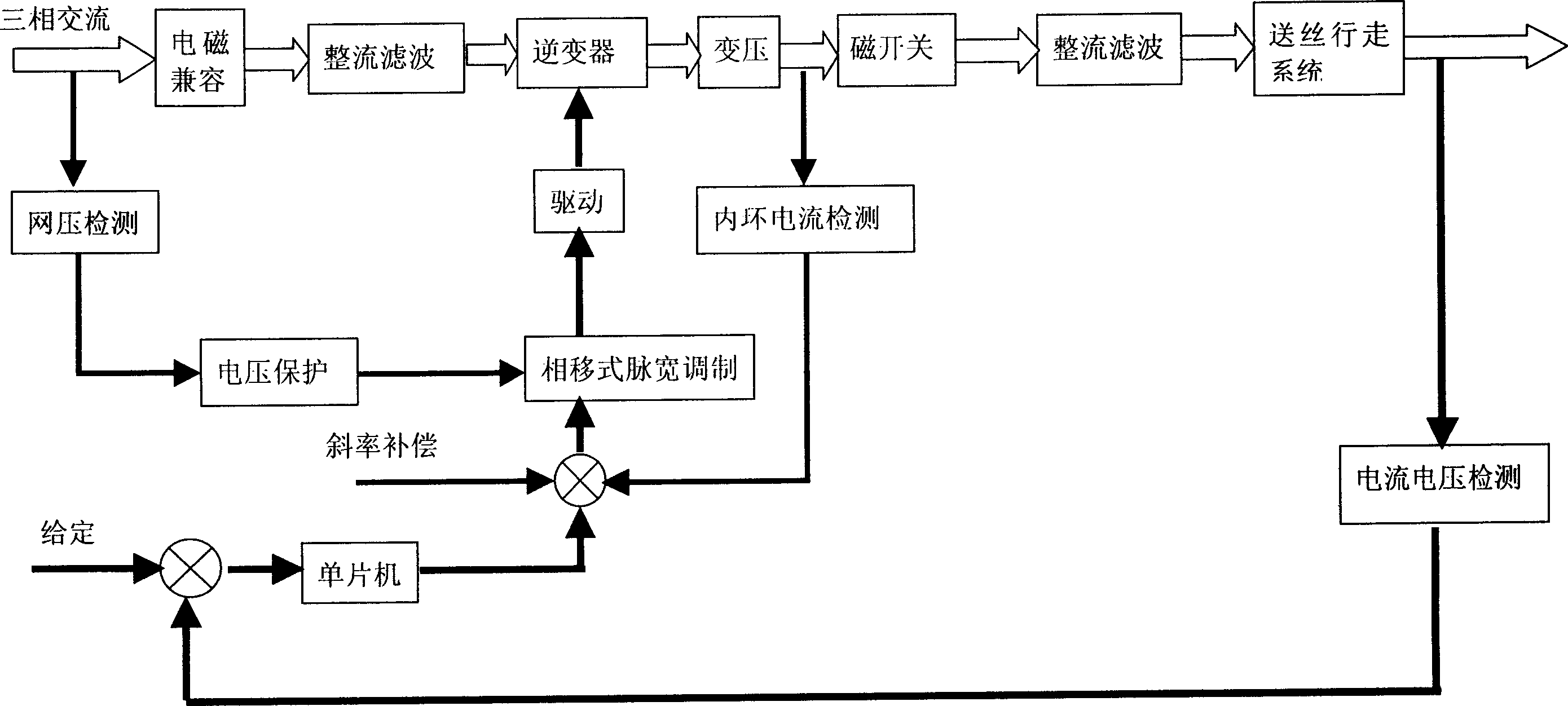

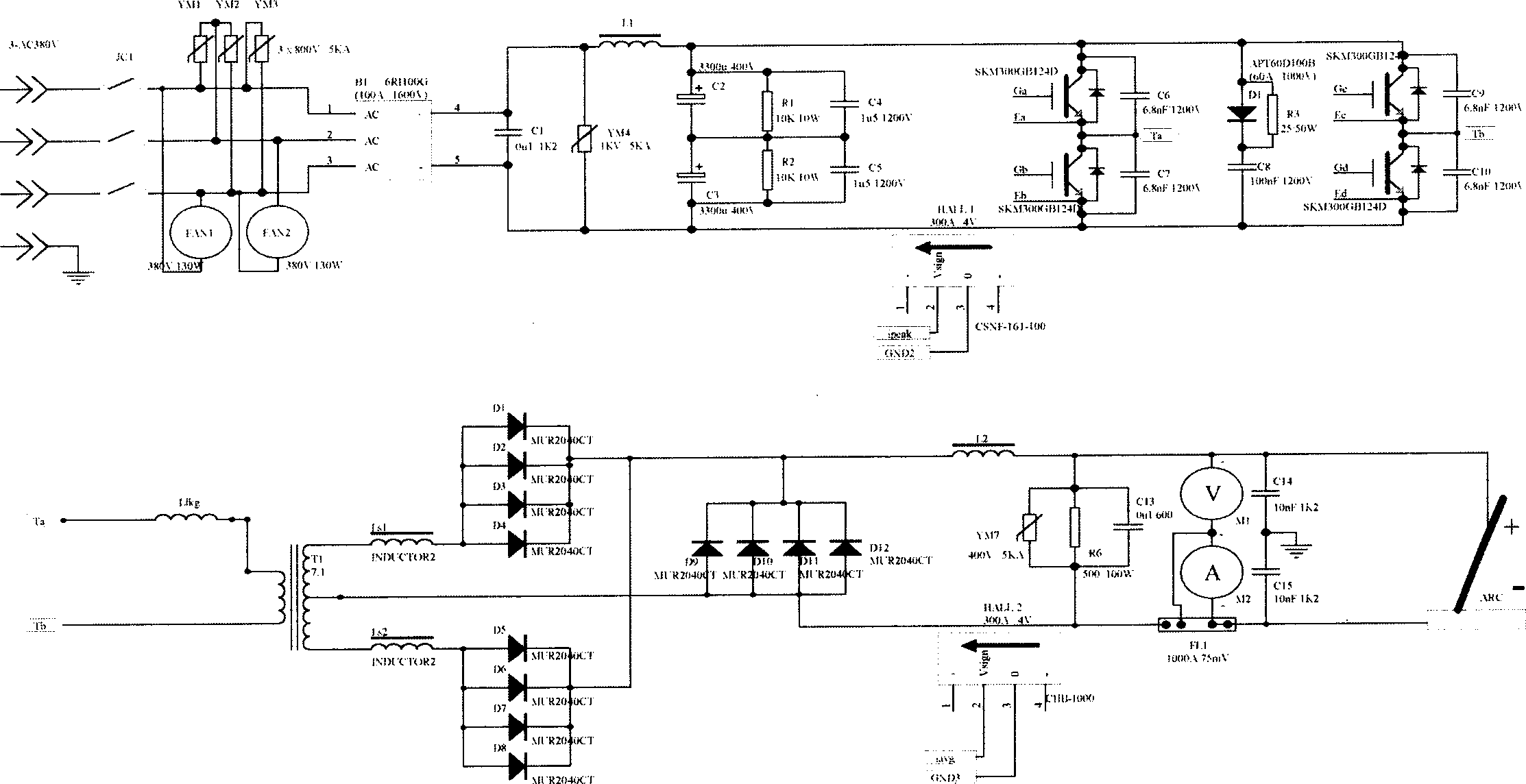

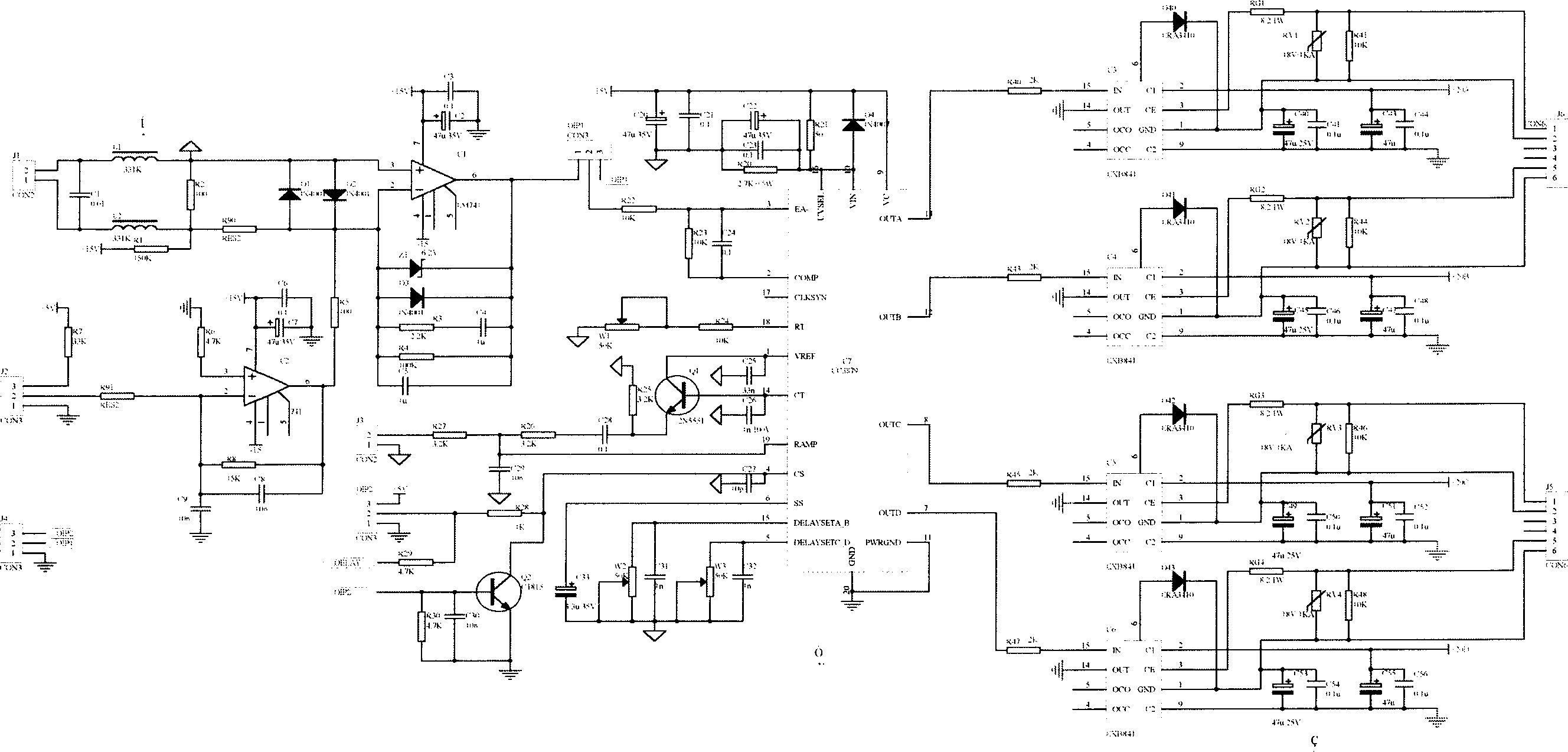

[0026] Such as figure 1 As shown, the three-phase power frequency alternating current is processed by electromagnetic compatibility, rectified and filtered to become a smooth direct current, which is used as the bus voltage (AC-DC) of the phase-shift zero-voltage inverter; the control system makes the switching tube at zero It is turned on and off under high voltage, so as to obtain 25KHz high-frequency high-voltage (DC-AC), and then after high-frequency transformer transformation, magnetic switch and secondary high-frequency rectification and filtering, several parameters suitable for the submerged arc welding process are obtained. Ten volts of direct current (AC-DC), together with the wire feeding traveling mechanism, completes the welding task. The control and driving circuit controls the normal operation of the power supply and the wire f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com