Preparation of 8-hydroxy-quinoline modified polyacrylonitrile fiber

A technology of polyacrylonitrile fiber and hydroxyquinoline, applied in the field of polyacrylonitrile fiber, can solve the problems of difficult preservation of fiber membrane, low chelating capacity of modified fiber membrane, low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, put the polyacrylonitrile hollow fiber and hydrazine hydrate in the ratio of 1:20 in the reactor, and react at 100°C for 2 hours to obtain the product (1); mix the product (1) with diethylenetriamine Put it into the reactor at a ratio of 1:50, and react at 80°C for 10 hours to obtain the product (2); mix the product (2) with sodium nitrite at a ratio of 1:1, and in acetic acid medium, -5 ℃ for 4 hours to obtain the product (3); after the product (3) was filtered and washed with water at 0 ℃, it was reacted with the ethanol solution of 8-hydroxyquinoline in a ratio of 2:1 for 6 hours to produce 8-hydroxyquinoline Quinoline chelated polyacrylonitrile fibers.

Embodiment 2

[0019] Embodiment 2, put polyacrylonitrile hollow fiber and hydrazine hydrate in the ratio of 1:60 in the reactor, react at 60 ℃ for 16 hours, and make product (1); product (1) is mixed with diethylenetriamine Put it into the reaction kettle at a ratio of 1:80, and react at 100°C for 2 hours to obtain the product (2); mix the product (2) with sodium nitrite at a ratio of 1:10, in acetic acid medium, 10°C The product (3) was reacted at lower temperature for 1 hour to obtain the product (3); after the product (3) was filtered and washed with water at 0°C, it was reacted with the ethanol solution of 8-hydroxyquinoline in a ratio of 2:4 for 1 hour to make 8-hydroxyquinoline Phenyl chelated polyacrylonitrile fibers.

Embodiment 3

[0020] Embodiment 3, put polyacrylonitrile hollow fiber and hydrazine hydrate in the ratio of 1:100 in the reactor, react at 60 ℃ for 8 hours, and obtain product (1); product (1) is mixed with diethylenetriamine Put it into the reaction kettle at a ratio of 1:20, and react at 80°C for 16 hours to obtain the product (2); mix the product (2) with sodium nitrite at a ratio of 1:5, in acetic acid medium, 5°C The product (3) was reacted at lower temperature for 4 hours to obtain the product (3); after the product (3) was filtered and washed with water at 0°C, it was reacted with the ethanol solution of 8-hydroxyquinoline in a ratio of 2:2 for 16 hours to make 8-hydroxyquinoline Phenyl chelated polyacrylonitrile fibers.

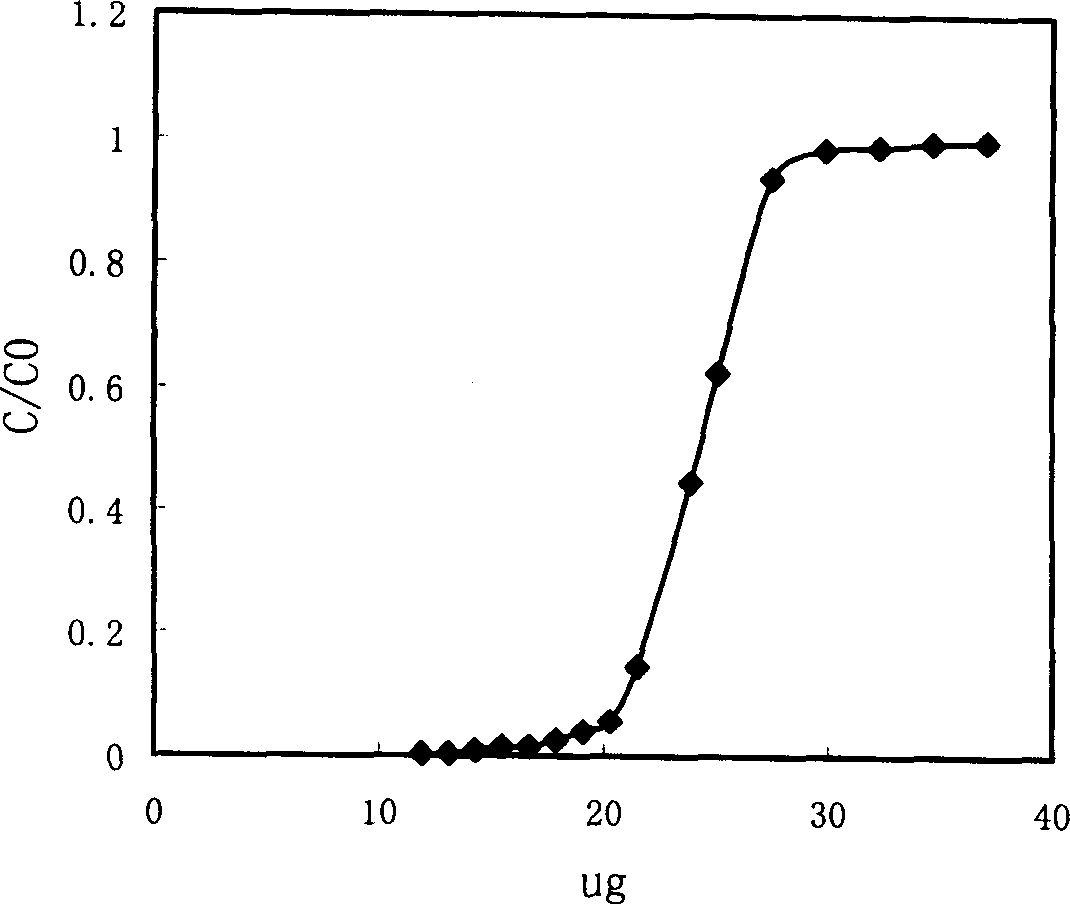

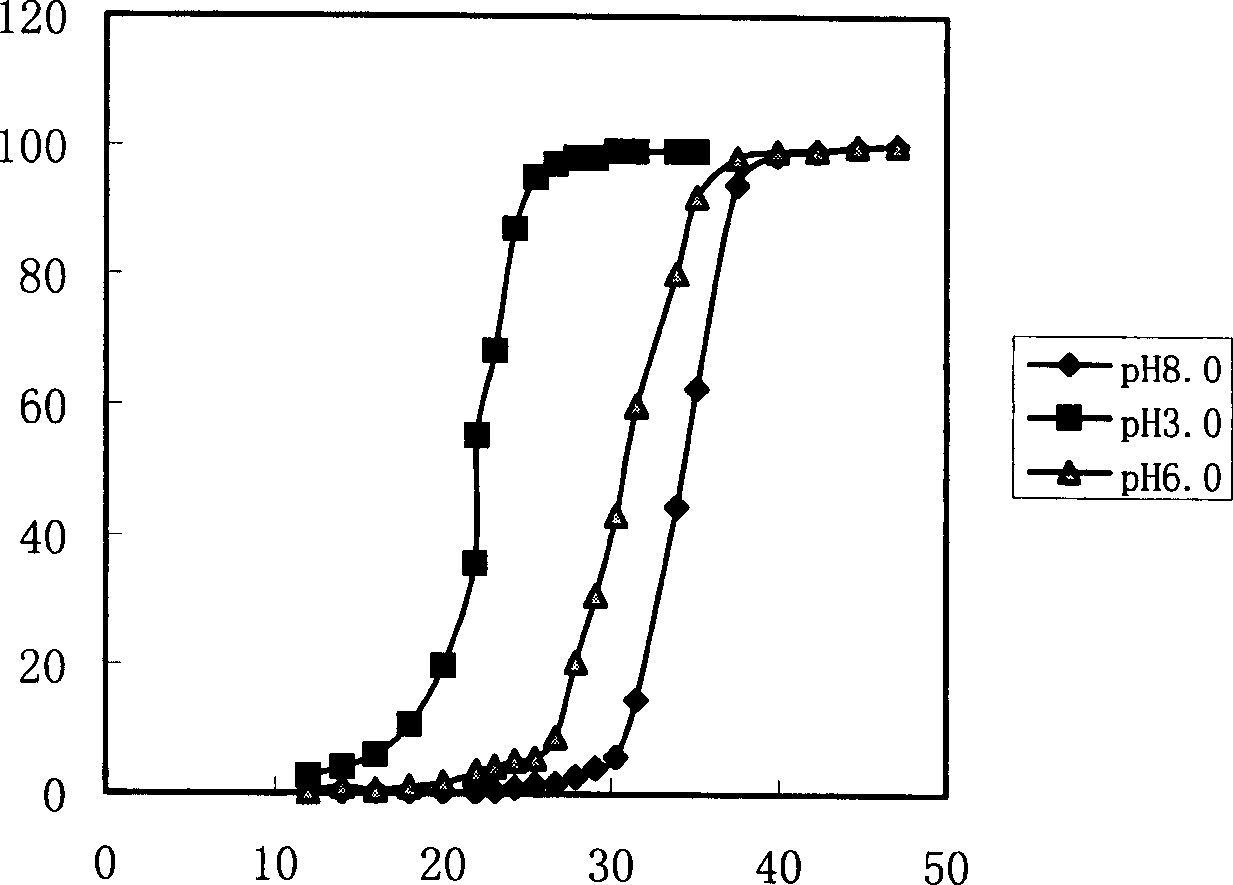

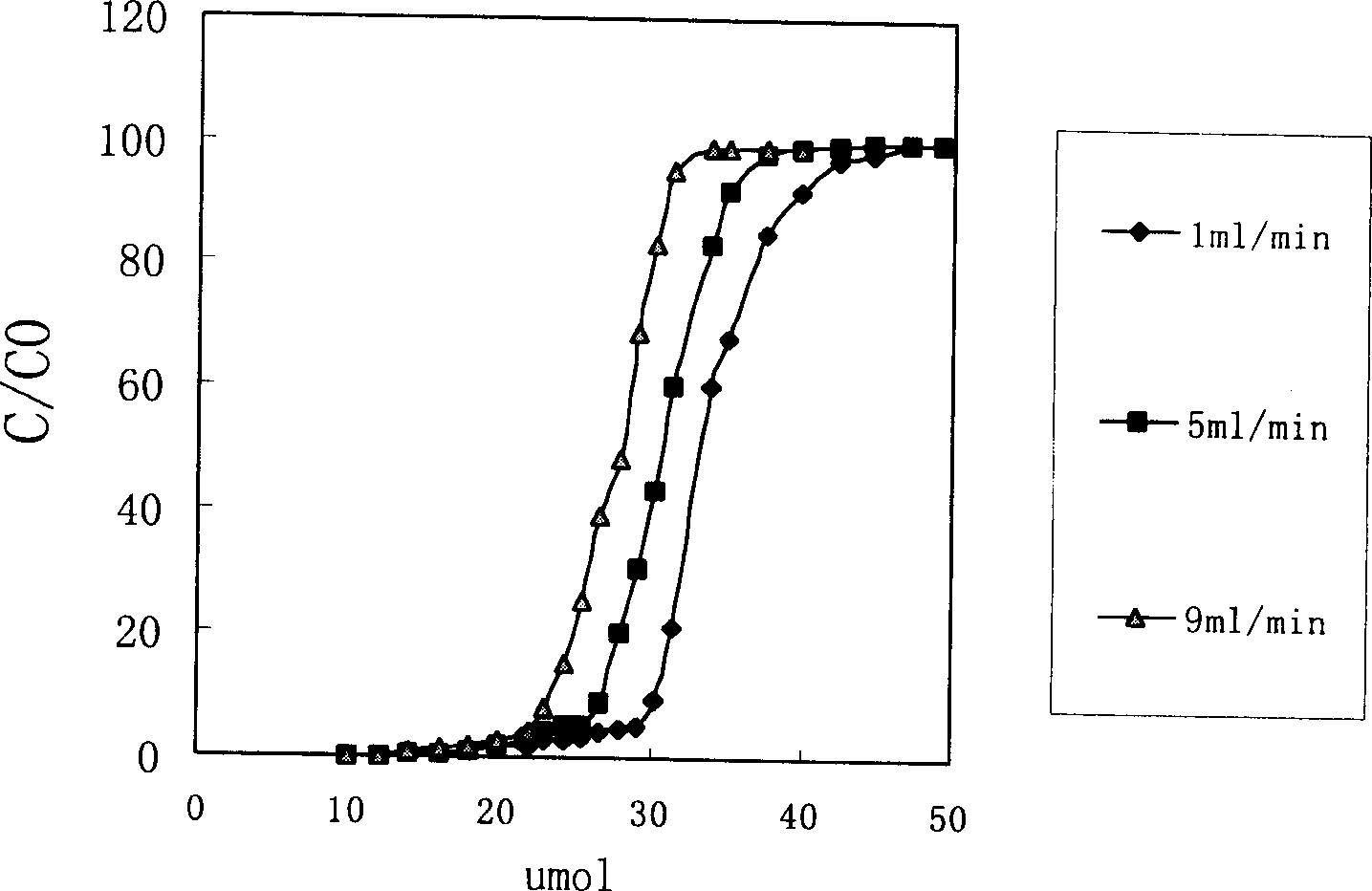

[0021] Through following test example, can know the performance of the 8-hydroxyquinoline chelate fiber that above-mentioned embodiment makes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com