Method for producing protease of thermophilic bacteria by using artificial gene

A technology of thermolysin and production method, applied in the field of artificial gene production of thermolysin, can solve the problems of high production cost, high cost of thermolysin, low enzyme yield and the like, and achieves low cost, thermolysin The effect of high activity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

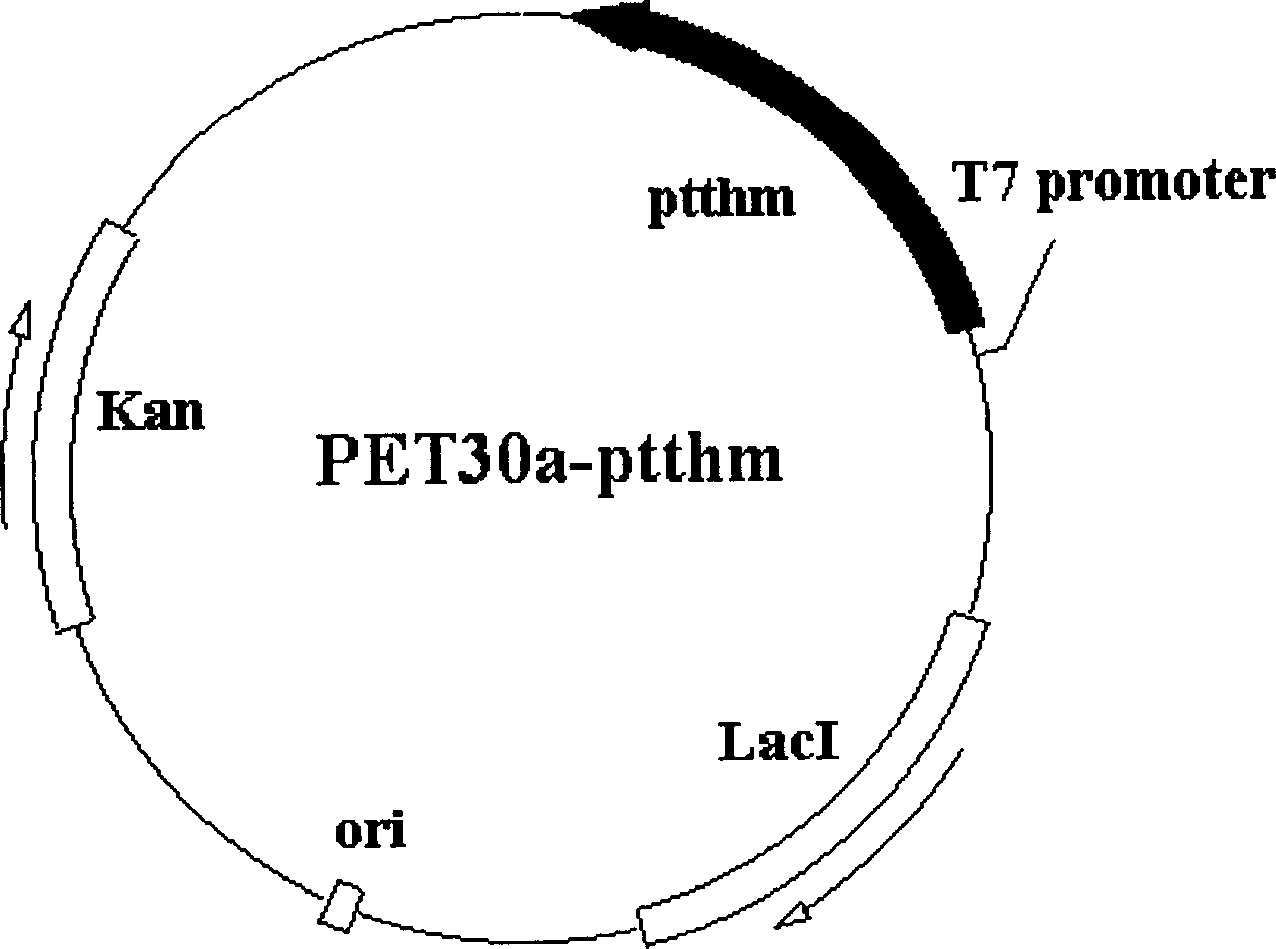

Image

Examples

Embodiment 1

[0020] The present invention is further described below by way of examples. Example 1: The cloning of the full-length protease gene and the construction of the expression vector are the same as above.

[0021] 1. Expression and separation and purification of inclusion bodies

[0022] The constructed expression vector—transformed Escherichia coli BL21(DE3) was inoculated in 1000mL culture medium and cultivated to OD 600 When it was 0.4, IPTG was used to induce expression for 3 hours, collect a certain amount of expressing bacteria, add 4ml / ml lysozyme after washing, treat at 37°C for 30min, break up the bacteria with ultrasonic waves, collect inclusion body precipitates, and use 1.5mol / L containing Washing solution of urea (50mMol Tris-HCl, 10mMol Ca 2+ , pH7.4, 1.5mol / L urea) repeatedly washed inclusion bodies, dissolved in a solution containing 6mol / L urea (50mMol Tris-HCl, 10mMol Ca 2+ , pH7.4, 6mol / L urea) to denature the protein.

[0024]...

Embodiment 2

[0028] According to the above method, the enzyme activity was determined to be 3 million U / g. Example 2: The cloning of the full-length protease gene and the construction of the expression vector were the same as above.

[0029] 1. Expression and separation and purification of inclusion bodies

[0030] The constructed expression vector—transformed Escherichia coli BL21(DE3) was inoculated in 10L culture medium and cultivated to OD 600 When the temperature is 0.6, induce expression with IPTG for 6 hours, collect the expressed bacteria, add 4ml / ml lysozyme after washing, treat at 37°C for 30min, break the bacteria with ultrasonic waves, collect inclusion body precipitates, and wash with 3.0mol / L urea solution (50mMolTris-HCl, 10mMol Ca 2+ , pH7.4, 3.0mol / L urea) repeatedly washed inclusion bodies, dissolved in a solution containing 9mol / L urea (50mMol Tris-HCl, 10mMol Ca 2+ , pH7.4, 9mol / L urea) to denature the protein.

[0031] 2. Drying of protein

[0032] The above protei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com