Bis-beta-hydroxyethyle terephthalate

A technology of hydroxyethyl terephthalate and methanol solution, which is applied in the field of manufacturing aromatic polyester, and can solve problems that cannot be solved fundamentally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 64 kg of crushed flakes of a used vial (made of polyethylene terephthalate resin) and 450 kg of ethylene glycol (hereinafter referred to as EG) into 1m 3 Add 0.32kg of caustic soda (NaOH) as a transesterification catalyst to an autoclave with a stirrer, depolymerize for 3.3 hours while distilling off a small amount of water and other low boiling point substances under the condition of 220°C and 0.15MPa, and obtain EG as the main Solvent, a solution containing bis-β-hydroxyethyl terephthalate (hereinafter referred to as BHET) as the main solute. This solution was filtered to remove a small amount of inclusions, then cooled to 55° C., and decolorized using activated carbon to obtain 510 kg of the solution. The total cation content relative to the concentrated solute (crude BHET) in the solution was 2.660 ppm, and the total anion content was 23 ppm.

[0037] For this, 210 kg of the solution was decationized at a temperature of 55° C. with a cation-exchange resin (Ambe...

Embodiment 2~4

[0042] For the pulverized flakes of 2 kinds of used vials (made of PET resin) that are different from recovery sources, get 53kg respectively as raw material, add 370kg EG simultaneously, the situation is the same as embodiment 1, but, replace caustic soda with 0.27kg sodium methylate as Depolymerization catalyst, carry out depolymerization, then filter, then carry out decolorization treatment with gac, obtain the crude BHET solution of each 420kg. The total cation contents relative to the crude BHET in the solution were 2,000 ppm and 2,050 ppm, respectively, and the total anion contents were 20 ppm and 22 ppm, respectively.

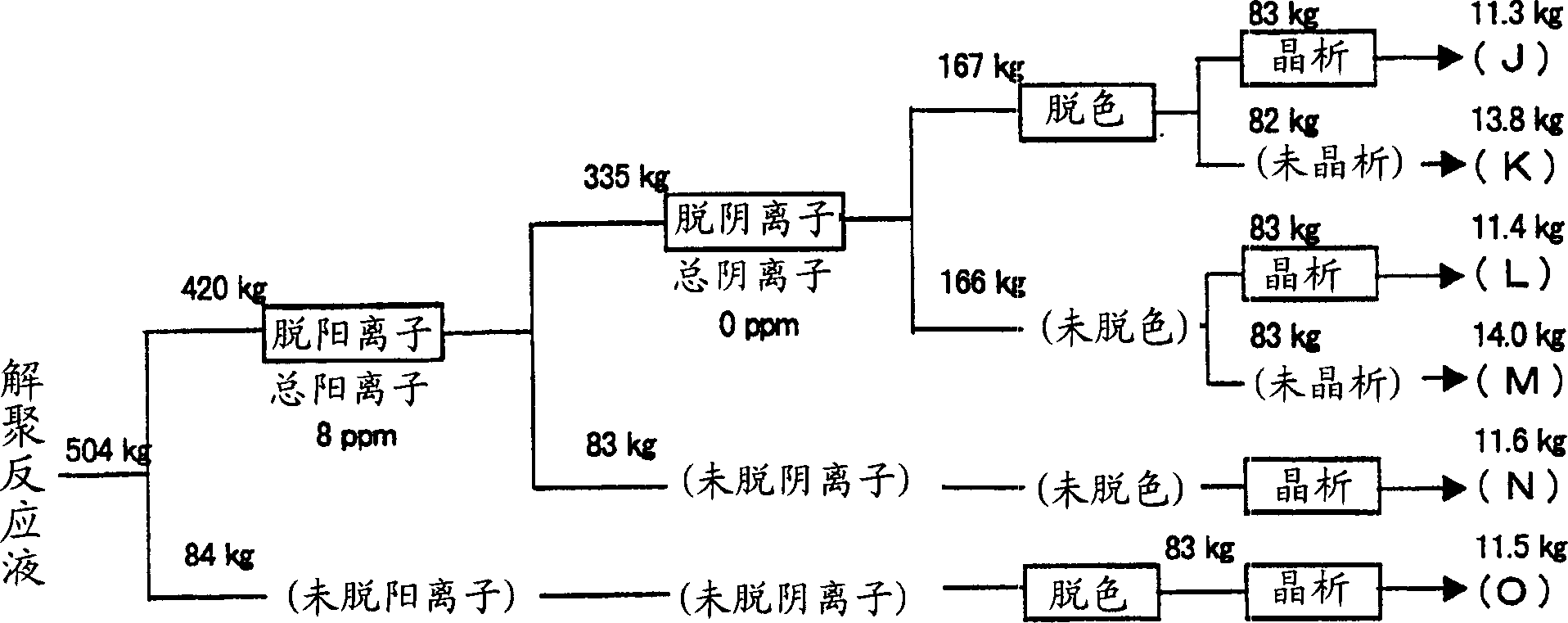

[0043] The entire amount of the two solutions were decationized and deanionized at a temperature of 55°C, respectively. The ion exchange resin used in the treatment was the same as in Example 1. The total cation contents in the treated solution relative to the crude BHET were 8 ppm and 12 ppm, and the total anion contents were 0 ppm and 1.0 ppm, respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com