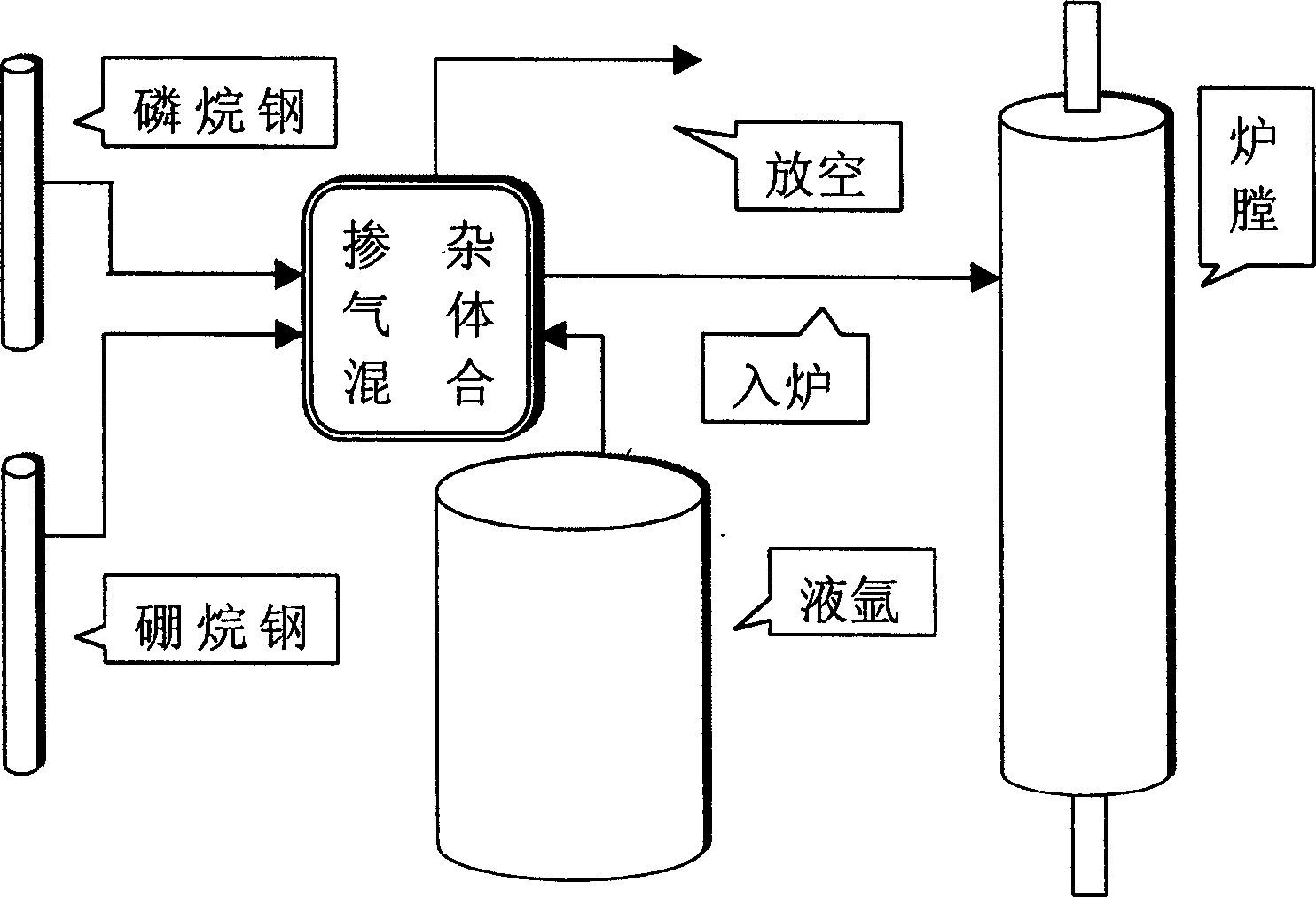

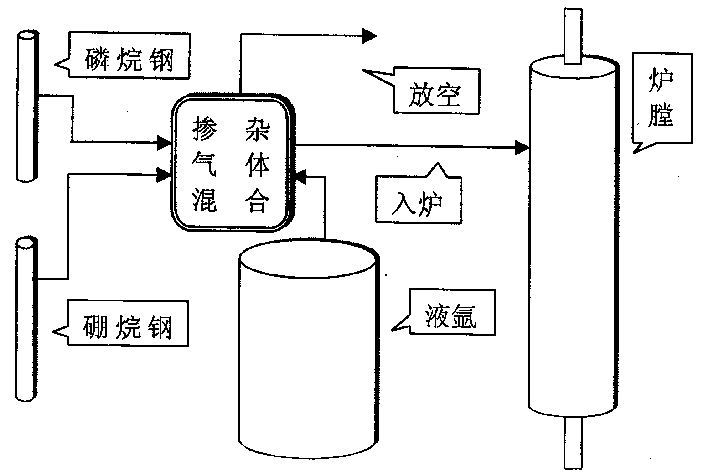

Gas-phase doping-area fused silicon monocrystal production method

A gas-phase doping and production method technology, which is applied in the directions of single crystal growth, self-region melting method, crystal growth, etc., can solve the problems of thermal instability and reversibility of resistivity, long production cycle and high production cost, and achieve shortening The production cycle, the elimination of intermediate damage, and the effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Provide examples below to further illustrate how the present invention is realized.

[0008] 1. The main equipment and raw materials of this embodiment are as follows:

[0009] Zone Furnace: Model: FZ-14-1, FZ-30; Doping Controller: Model: 0154E

[0010] Polysilicon: primary material: base boron ≥ 9000Ω·cm base phosphorus ≥ 900Ω·cm

[0011] CFZ material: base boron≥600Ω·cm, base phosphorus≥400Ω·cm

[0012] High-purity argon: Dew point: -70°C Purity: >99.9993% Oxygen content ≤1PPma

[0013] Hydrofluoric acid: high grade pure

[0014] Nitric acid: high grade pure

[0015] Phosphine: Purity: 99.999%

[0016] Seed crystal: For the inspection standard, please refer to "Silicon Wafer Inspection Operation Procedures"

[0017] 2. The main raw material consumption quota of this embodiment:

[0018] It takes consumption to pull 1kgΦ3″ qualified single crystal for one crystal formation (take ASIMI material as an example)

[0019] Polysilicon: 1.6kg; Hydrofluoric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com