Silver containing copper alloy

A technology of copper alloy and weight gauge, which is applied in the direction of metal/alloy conductors, contact parts, circuits, etc., can solve the problems of bending formability and stress relaxation resistance that have not been reported, and achieve enhanced stress relaxation resistance and bending forming sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

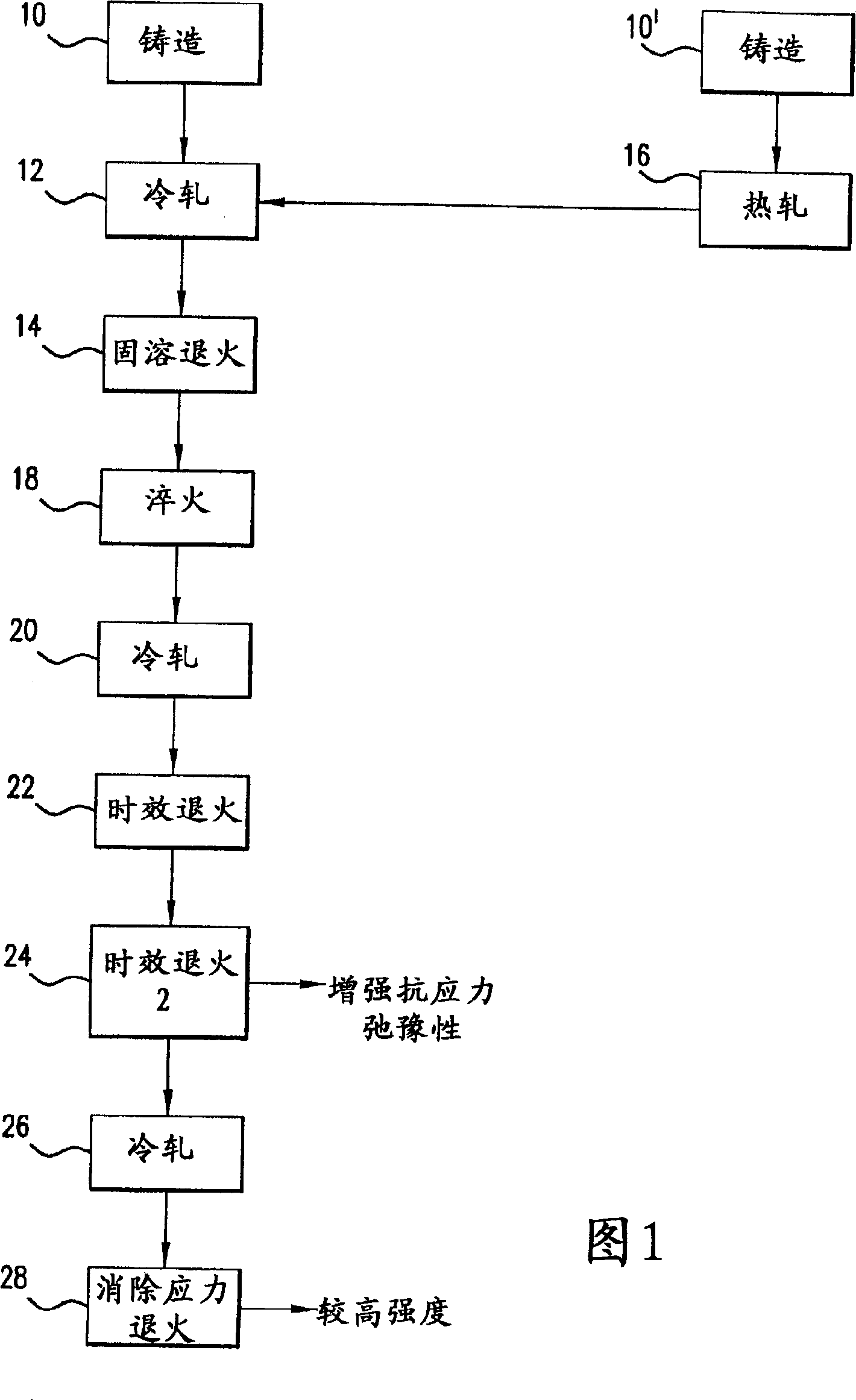

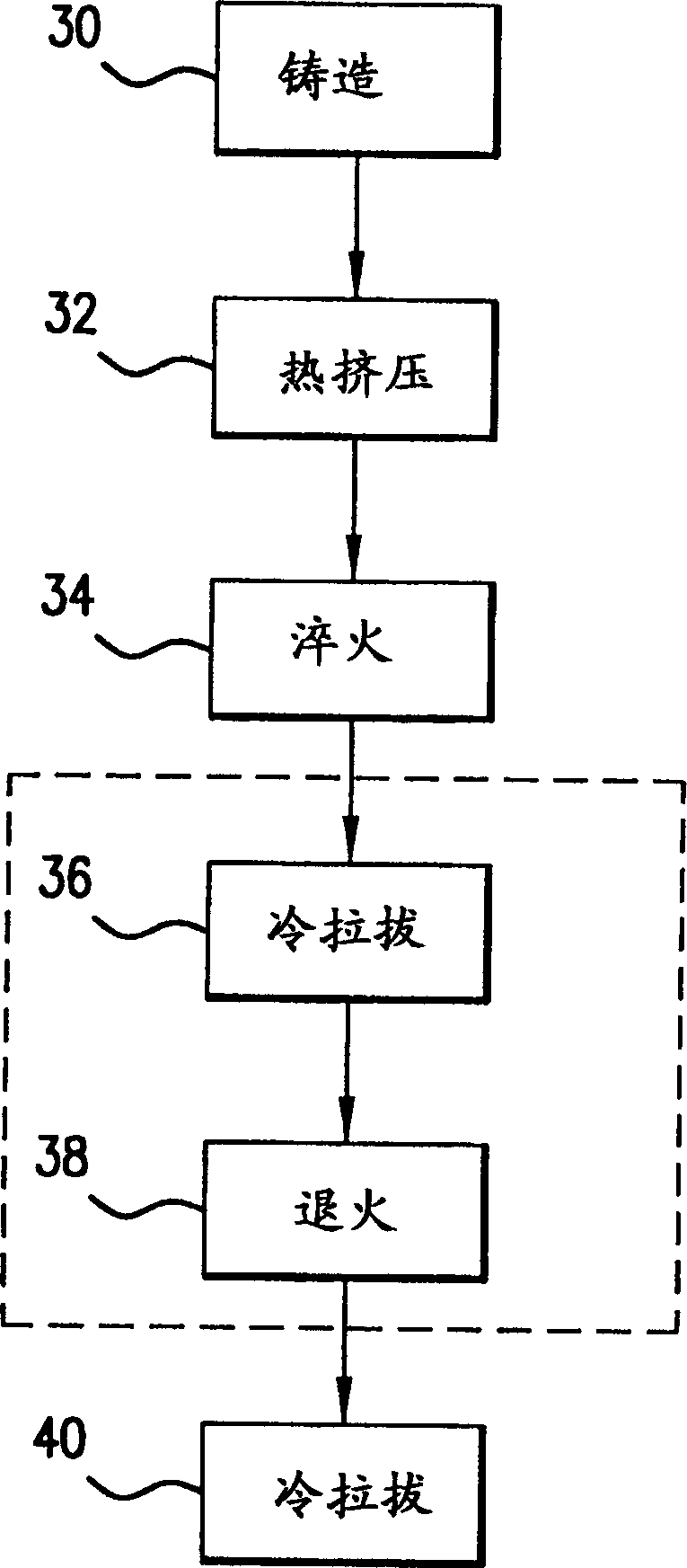

Method used

Image

Examples

Embodiment 1

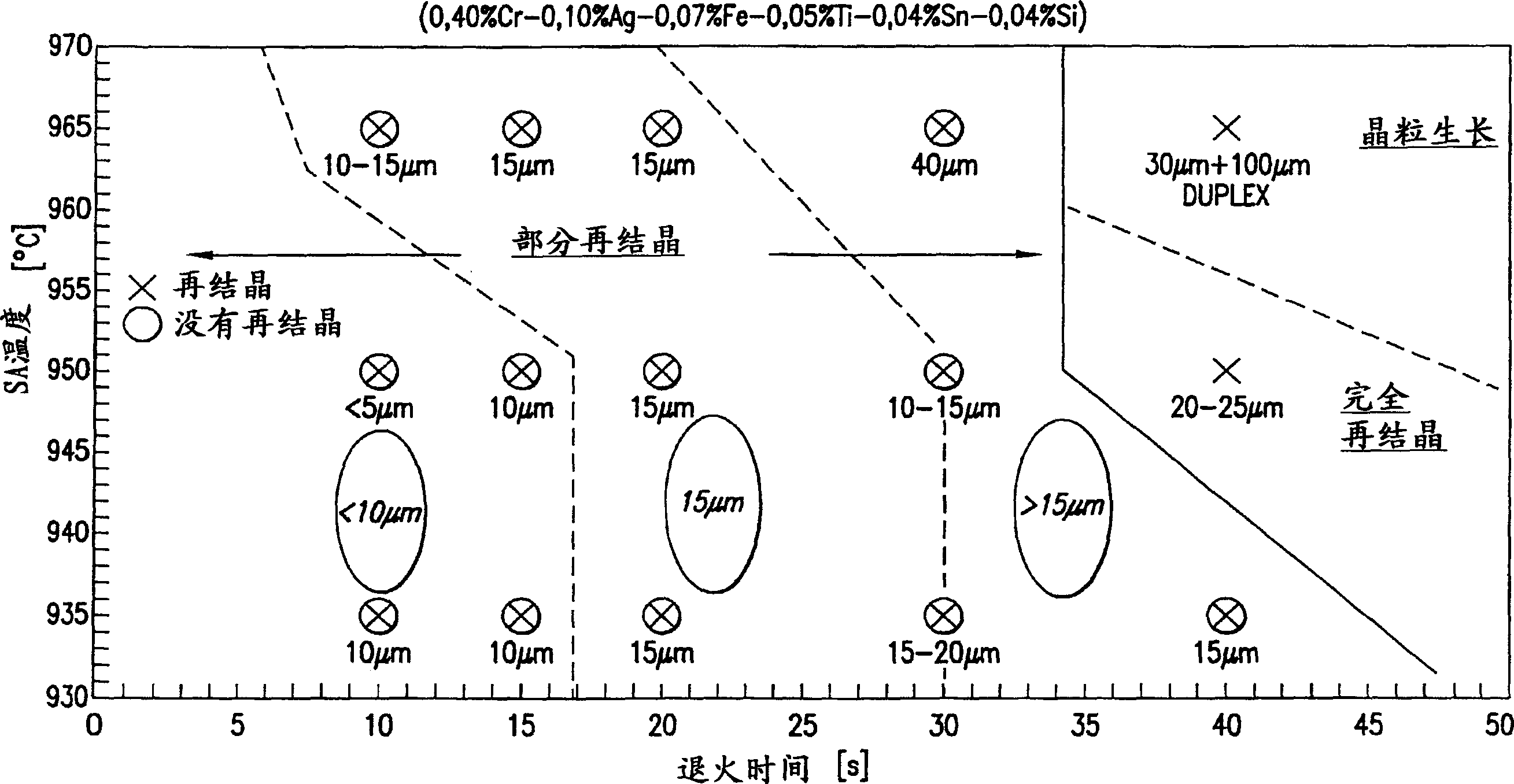

[0108] Copper alloys having a nominal composition of: 0.55% chromium, 0.10% silver, 0.09% iron, 0.06% titanium, 0.03% silicon, 0.03% tin and the balance copper and unavoidable impurities, Cast into ingots by melting. The ingot is machined and hot rolled at 980°C, quenched and processed to obtain a strip with a thickness of 1.1 mm. The strips were cut into pieces of approximately 300mm in length, immersed in a molten salt bath at 950°C for 20 seconds, and then quenched with water to reach room temperature (nominally 20°C). The surface of the strip was cut by milling to remove surface oxides, then cold rolled to an intermediate gauge of 0.45 mm, heat treated at 470°C for 1 hour and then at 390°C for 6 hours. Thereafter, the strip was rolled to a final gauge of 0.3 mm and subjected to stress relief annealing at 280° C. for 2 hours.

[0109] The final product exhibits the following properties:

[0110] Yield strength = 84ksi (580MPa);

[0111] Elastic modulus = 145GPa;

[011...

Embodiment 2

[0122] Seven copper alloys having the compositions shown in Table 3 were melted and cast into 4.5 kg (10 lb) ingots in steel molds. After pouring, the ingot size was 102mm×102mm×44.5mm (4″×4″×1.75″). The ingot was kept at 950°C for 2 hours and then hot rolled to 12.7mm (0.50″) in six passes thickness and quenched in water. After edge trimming and milling to remove scale, the alloy was cold rolled to a nominal thickness of 1.14 mm (0.045"), solution heat treated in a fluidized bed furnace at 950°C for 20 seconds, and then water quenched.

[0123]The alloy was then sequentially cold rolled to a 60% thickness reduction to a thickness of 0.46mm (0.018″) using several passes followed by a double aging anneal which consisted of a first static anneal at 470°C for 1 hour followed by It is a second static annealing at 390 ° C for 6 hours. This heat treatment can harden the alloy while increasing the electrical conductivity to a value greater than that of the cold-rolled state without ...

Embodiment 3

[0131] Tables 7A and 7B show that the compositions and processing methods of the present invention can result in improved bend properties. As shown in Table 7A, the inventive alloy J310 has isotropic bend properties when processed with a solution heat treatment (SHT), while the silver-free control alloy J306 has slightly anisotropic bend properties. When the control alloy K005 was processed with bell annealing (BA) and inserted cold rolling reduction, it had anisotropy and poor bending properties. The bend properties of alloys J306, J310 and K005 in Table 7A were evaluated using the mandrel method and it was found that this method gave bend values at least 0.5 times higher than the V-block method.

[0132] When alloys K007 and K005 are subjected to a homogenization step at 850°C-1030°C for 1-24 hours, hot rolling is carried out at a temperature of 600°C-1000°C, followed by a cooling rate of 50°C-1000°C per minute Lower quenching. These steps are followed by cold rolling at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com