Microporous super fine fiber base cloth and process for manufacturing the same

A superfine fiber, microporous technology, applied in fiber processing, conjugated synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of failing to present fluffy touch and bright luster, and achieve bright luster and sound insulation. The effect of good sex and superior fluff touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (dissolution type fibrillation fiber)

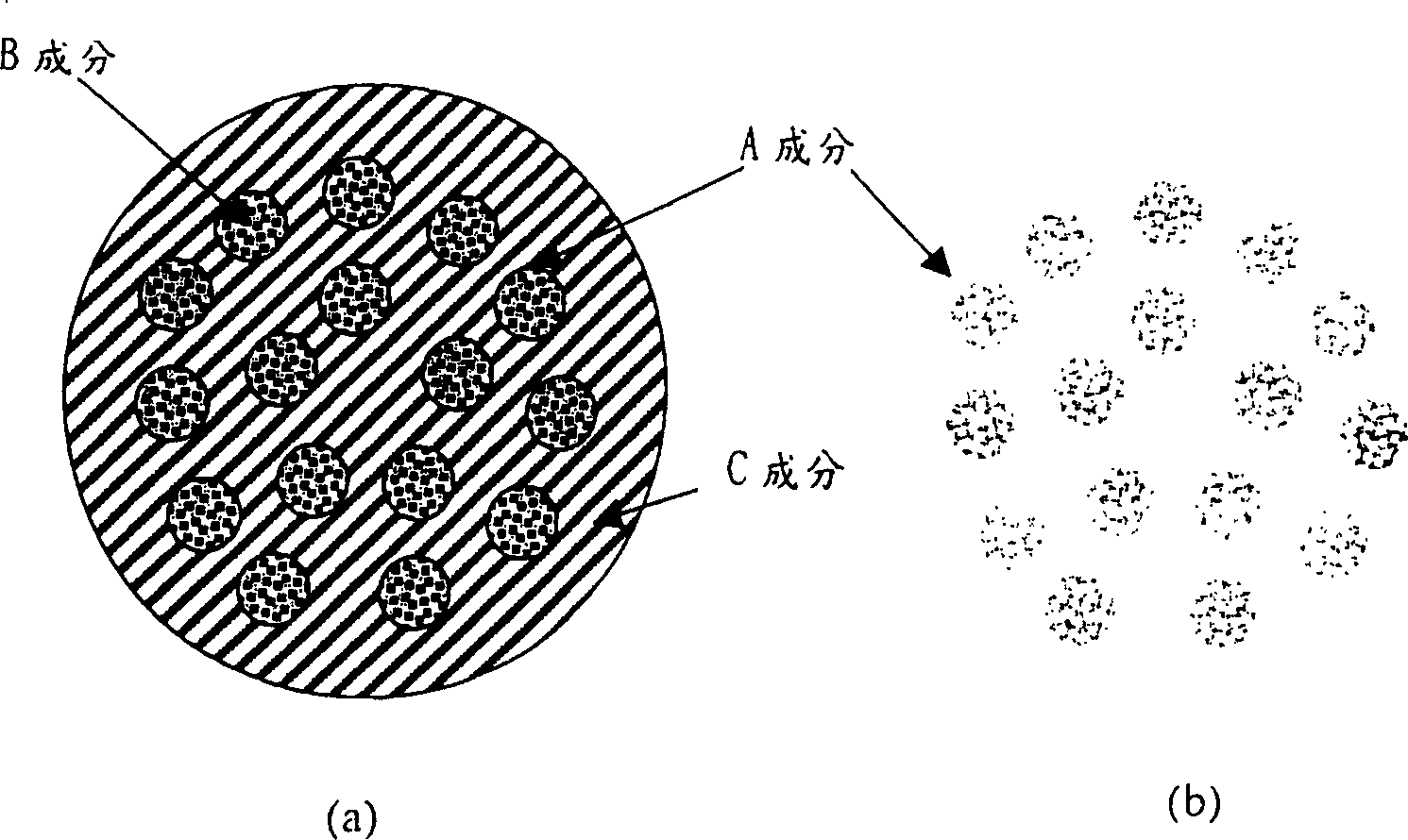

[0044]Polyamide is used as component A and polystyrene is used as component C to carry out composite spinning in a ratio of 60 / 40, wherein 10% polystyrene of component B is added to component A polyamide, and the melting of spinning head and spinneret The temperature is 280°C, the coiling speed is 900m / min, and the unstretched yarn with a fineness of 10dpf, a strength of 1.35g / den, and an elongation of 450% is obtained. The cross-section of the yarn is observed with an optical microscope, and it is found that the polyamide part of the A component There are 1,000 to 1,500 small islands of different sizes (component B polystyrene). The unstretched yarn is stretched at a stretching temperature of 80°C and a stretching ratio of 250%, and then dried and cut into cotton after stretching to obtain a fineness of 4.0dpf, a strength of 3.7g / den, and a tensile strength of 3.7g / den. Superfine porous fiber cotton with a length of...

Embodiment 2

[0046] Embodiment 2 (physics splitting fiber)

[0047] Polyamide is used as A component and polyethylene terephthalate containing 10 mol% IPA (isophthalic acid) is used as C component to carry out composite spinning in a ratio of 80 / 20, wherein A component polyamide is added with 30% B-component thermoplastic polyvinyl alcohol (PVA) polymer, the melting temperature of the spinneret nozzle is 275 ° C, the coiling speed is 700m / min, and the obtained fineness is 10dpf, the strength is 1.3g / den, and the elongation 380% unstretched yarn, using an optical microscope to observe the cross section of the yarn, found that there are 200 to 300 small islands of different sizes in the polyamide part of A component (B component polyvinyl alcohol). The unstretched yarn is stretched at a stretching temperature of 90°C and a stretching ratio of 230%, and then dried and cut into cotton after stretching to obtain a fineness of 4.5dpf, a strength of 3.0g / den, and an elongation of 4.5dpf. Superfi...

Embodiment 3

[0049] Embodiment 3 (dissolution type fibrillation fiber)

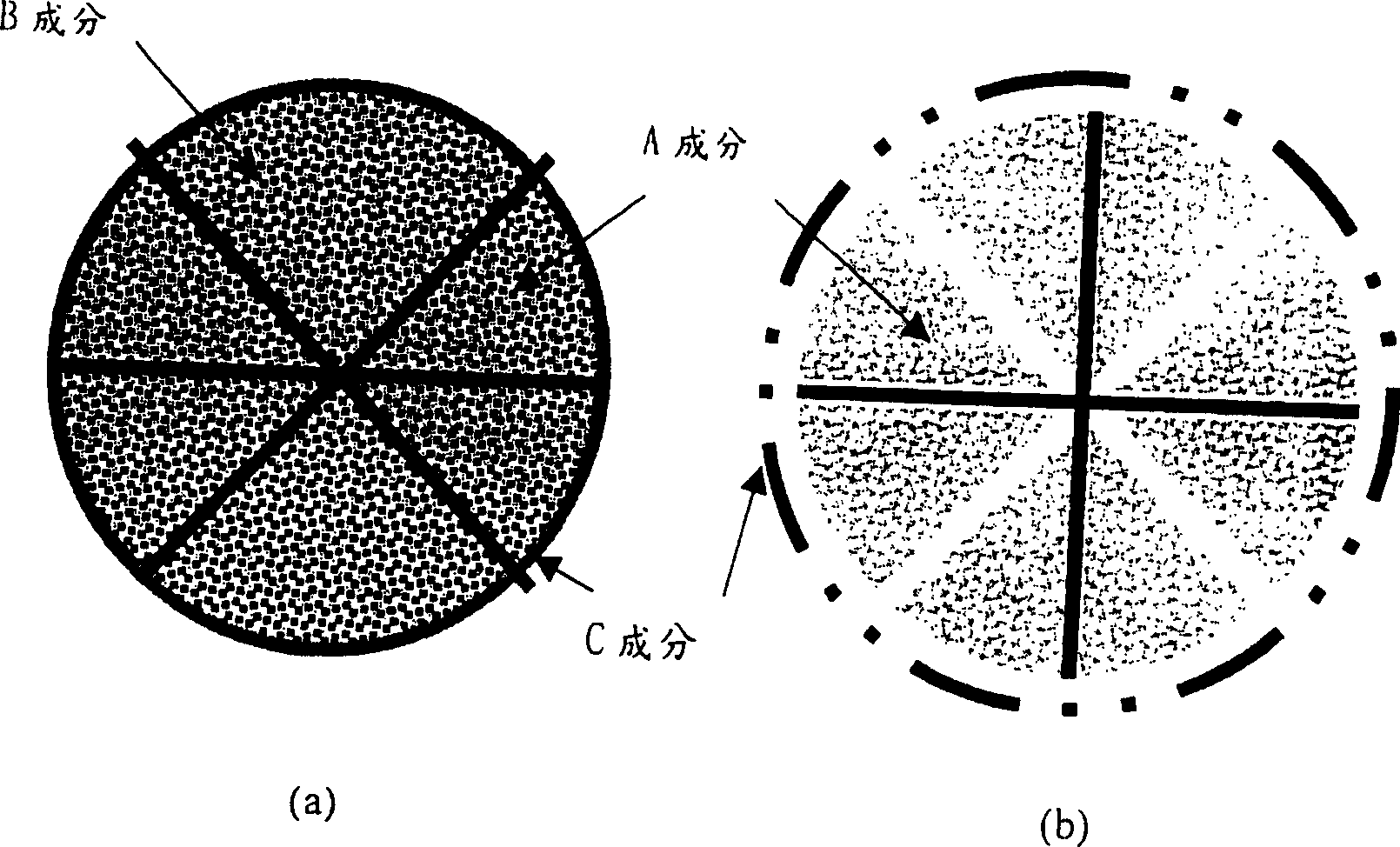

[0050] Using polyethylene terephthalate as component A and polyethylene terephthalate containing sulfonic acid sodium salt as component C for composite spinning in a ratio of 65 / 35, in which polyethylene terephthalate Add 30% thermoplastic polyvinyl alcohol (PVA) polymer of component B to the ester, the melting temperature of the spinneret nozzle is 285°C, the coiling speed is 3,000m / min, and the fineness is 150den / 32, and the strength is 3.0g / dpf, partially stretched yarn (POY) with an elongation rate of 80%, observed the cross section of the yarn with an optical microscope, and found that there were 500 to 1,000 pieces of different sizes in the polyethylene terephthalate part of A component Kojima (B component polyvinyl alcohol). This part of the stretched yarn (POY) is false twisted under the conditions of drawing temperature 150°C, drawing ratio 120%, speed 50m / min, twist 25t / m, and can obtain a fineness of 120de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com