Solid camera device and camera using same

A solid-state imaging device and semiconductor technology, applied in the field of passive AEAF solid-state imaging devices and cameras, can solve the problems of high price and large size of cameras, and difficulty in adopting small cameras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

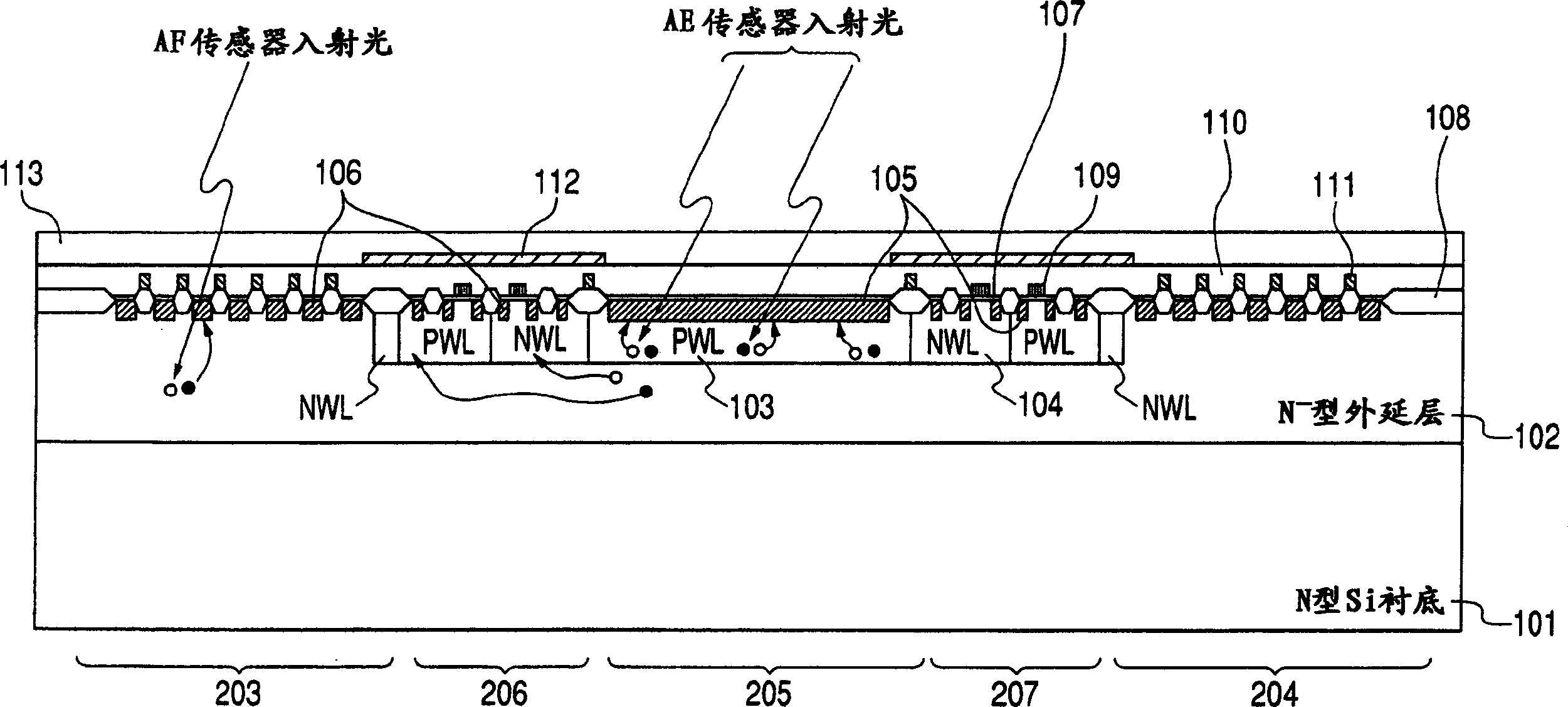

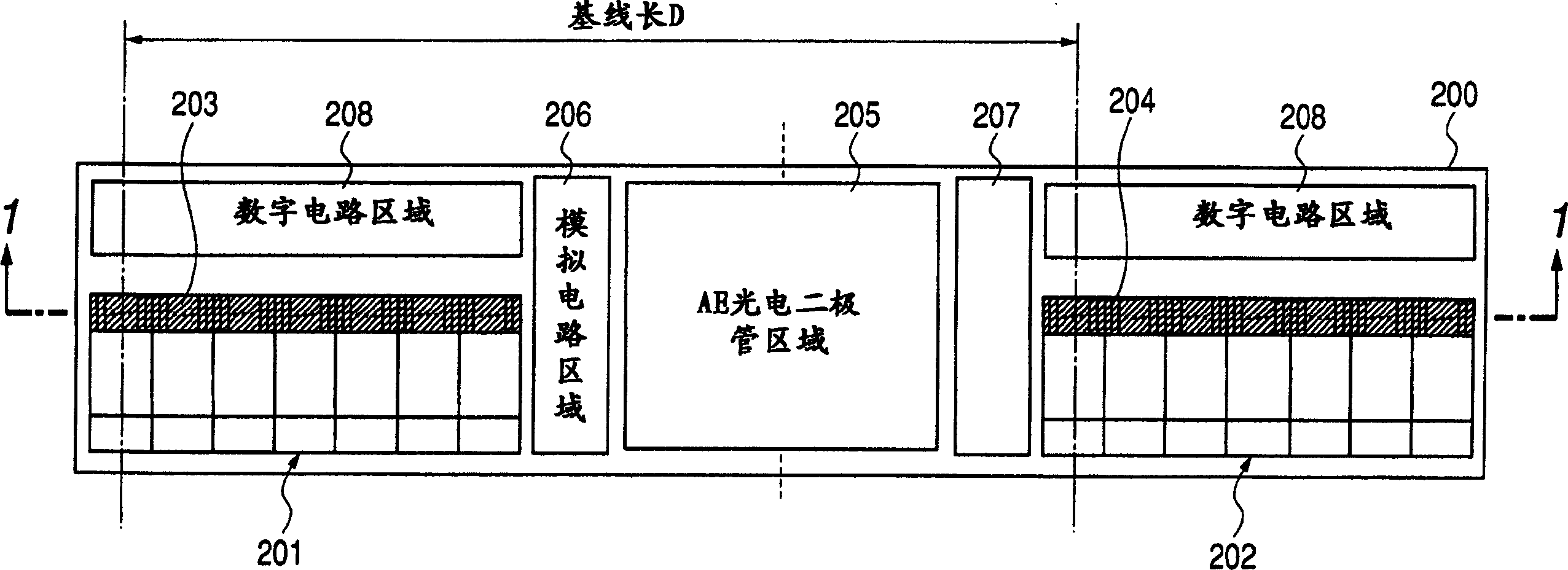

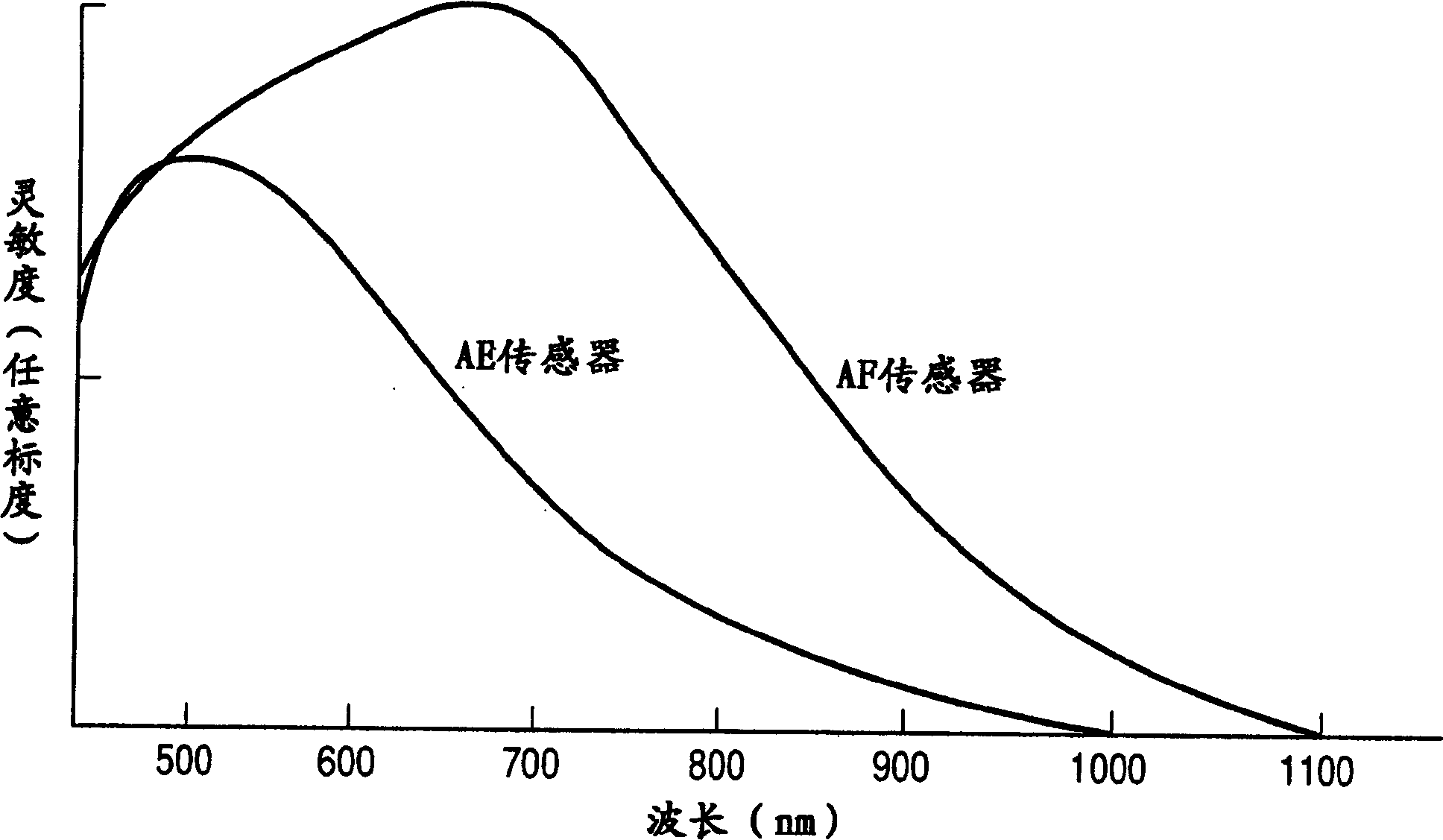

[0023] figure 1 It is a drawing which fully shows the characteristics of this invention, and is a schematic cross-sectional structure diagram of the solid-state imaging device of this invention. and, figure 2 A schematic plan layout of the solid-state imaging device of the present invention is shown in . figure 1 yes figure 2 1-1 Partial cross-sectional view. This example uses N - A solid-state imaging device manufactured by a double-well structure CMOS process of a P-type well (PWL) and an N-type well (NWL) of an epitaxial wafer.

[0024] figure 1 Among them, 101 is N-type Si substrate, 102 is N - Type epitaxial layer, 103 is P-type well (PWL), 104 is N-type well (NWL), 105 is N + Type impurity diffusion region (NSD), 106 is P + Type impurity diffusion region (PSD), 107 is a gate oxide film, 108 is a thick selective oxide film as an element isolation region, 109 is a POL (polysilicon) wiring that also serves as a gate of a MOS transistor, 110 is an interlayer ins...

Embodiment 2

[0031] Figure 4 A cross-sectional structural view of a solid-state imaging device according to a second embodiment of the present invention is shown. In this figure, 210 is N + Type impurity buried layer (NBL). For this embodiment, compared with the first embodiment, the N-type Si substrate 101 and N - The NBL 210 is provided between the epitaxial layers 102, and the potential barrier generated by the NBL can prevent the diffusion current from inside the Si substrate 101 from flowing into the photodiode of the AF sensor. In particular, since the photodiode for the AF sensor is formed in the epitaxial layer, the diffusion current of the Si substrate 101 has a great influence, and this embodiment will be very effective. Moreover, the method of internal degassing treatment is adopted in the process, which can further reduce the dark current.

[0032] In this embodiment, by reducing the dark current generated by the photodiode for the AF sensor, a solid-state imaging device f...

Embodiment 3

[0034] Figure 5 It is a cross-sectional structure diagram of a solid-state imaging device implementing the third embodiment of the present invention. In this figure, 300 is a low-concentration P-type well. In the first and second embodiments, the photodiode for the AF sensor is provided in the epitaxial layer, but in the present embodiment, the impurity concentration is low, and it is provided in the deep PWL 300 of the junction depth. The usual PWL103 has a surface concentration of 1×10 17 cm -3 About, for the junction depth below 1μm, the deep PWL300 should be formed in this way, using high-energy ion implantation equipment, so that the impurity concentration near the surface is about 1×10 16 cm -3 , PWL junction depth is more than 2μm. Therefore, the AF sensor is also formed in the PWL similarly to the AE sensor, so that an epitaxial layer is basically not required.

[0035] In this embodiment, the depletion layer of the photodiode for AF is extended to the PWL side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com