Method for producing acrylamide using film technique microbiological transformation

A microbial conversion and acrylamide technology, applied in fermentation and other directions, can solve the problems of high content of biological impurities in acrylamide products, complex equipment maintenance, high energy consumption, etc., to improve reaction efficiency and cell utilization, and simplify production equipment and processes , the effect of simplifying the ion exchange step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

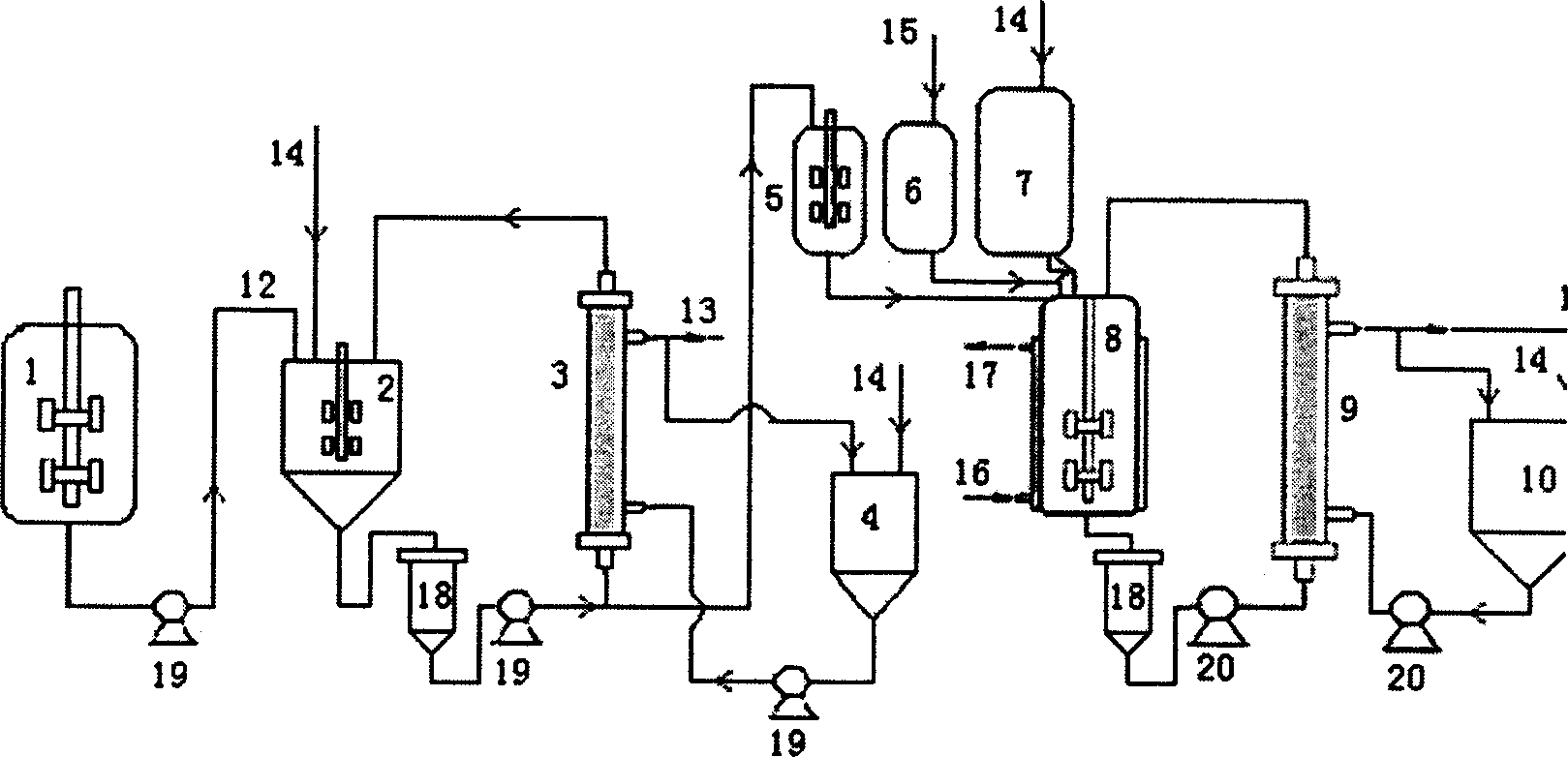

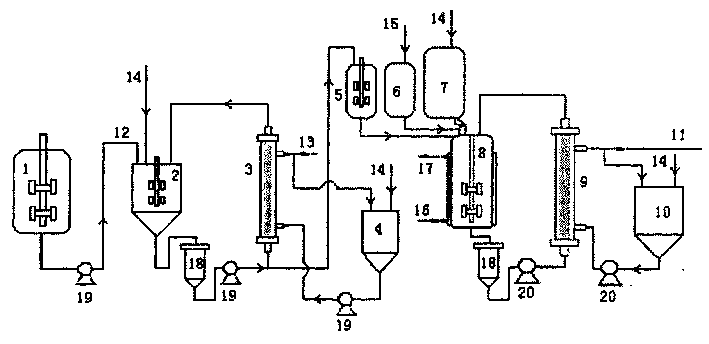

Image

Examples

Embodiment 1

[0011] (1) Bacteria are cultured in a 3m3 fermenter at 28°C. The main components of the medium are: glucose 20g / L; yeast extract powder 5g / L; urea 7.5g / L; sodium glutamate 1g / L ;K 2 HPO 4 0.5g / L; KH 2 PO 4 0.5g / L; MgSO 4 ·7H 2 O0.5g / L; inducer 60ppm. The pH value was adjusted to 7.5, and after 56 hours of cultivation, a total of about 1.2 tons of bacteria suspension was obtained, the wet bacteria content was 120g / L, and the enzyme activity reached 2669U / mL.

[0012] (2) Use a pump to send the bacterium supersuspension to the thalline washing tank, and feed cooling brine into the cooling jacket of the washing tank to control the temperature of the bacteria solution at 4-10° C. during the washing process.

[0013] (3) Start the circulation pump, the speed is 2900rpm, and the flow rate is 12.5m 3 / h, the bacterial suspension is filtered and concentrated through the hollow fiber microfiltration membrane, and the filtrate is discharged into the sewage treatment syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com