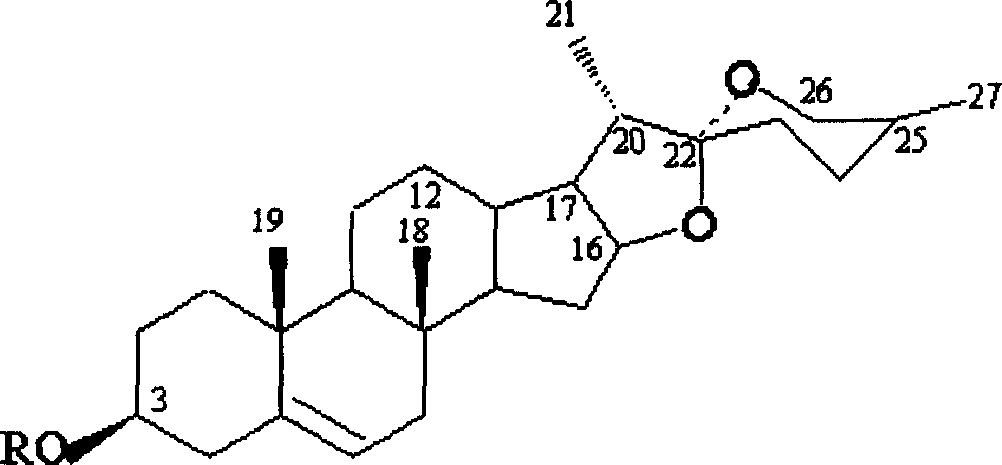

Method for preparing hypoglycosyl dioscin by enzyme method hydrolyzing yam saponin glycosyl

A technology for diosgenin and saponin sugar, which is applied in the field of preparing low-glycosylated diosgenin, can solve the problems of large saponin breakage and pollution, and achieve the effects of low hemolysis, high curative effect and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a. Take thermoaerobic bacteria Bacillus sp.JF 2 Bacteria (document 1) were cultured with ventilation at a temperature of 60°C for 30-40 hours in a culture medium containing 3% corn flour, 0.2% enzyme-producing inducer - yam extract (dry matter), 0.01% MgSO4, and centrifuged to remove Bacteria, adding 65% saturated ammonium sulfate to the supernatant (containing the mixed solution of enzyme) to precipitate the enzyme protein, dialyzing with 0.02M, pH5 acetic acid buffer, centrifuging to remove slag, freeze-drying to obtain saponinase;

[0033] b. Get 2 grams of the above-mentioned saponin enzyme, 30 grams of dioscin 1, 1500 milliliters of acetic acid buffer (0.2M, pH5.0) and 150 milliliters of ethanol and mix evenly, so that 30 grams of dioscin 1 accounts for 0.1- 10%, stirred and reacted at a temperature of 75°C for 4 hours;

[0034] c. Add 6000 ml of ethanol after the reaction, filter to remove the protein precipitate, and evaporate the filtrate to dryness under reduc...

Embodiment 2

[0039] Other conditions are the same as in Example 1, except that 0.2% of the enzyme-producing inducer in the culture medium—the yam extract (dry matter) is 0.05% of flavonoids.

Embodiment 3

[0041] a. Aspergillus niger (Aspegillus niger) was cultured with agitation and ventilation at a temperature of 28-30°C for 50 days in a medium containing 5% malt extract and 1% enzyme-producing inducer—dioscin extract (dry matter). -100 hours, centrifuge and sterilize to obtain an enzyme-containing mixture, use 60-75% saturated ammonium sulfate to precipitate the enzyme protein, collect the protein, and dissolve it in acetic acid buffer (0.02M, pH5.0) of 1 / 10 of the fermentation broth volume In , dialyze to remove ammonium sulfate, and centrifuge to remove slag, which is the enzyme solution;

[0042] B. get 3 grams of dioscins, 100 milliliters of acetic acid buffer (0.02M, pH5.0) and 50 milliliters of above-mentioned enzyme liquids and mix, make 3 grams of dioscins 1 account for 0.1-10% of total reaction volume, at temperature React at 4°C for 40 hours;

[0043] c. adding 1 / 3 volume of n-butanol to extract the saponins three times, and evaporating to dryness under reduced pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com