Prepn and application of alkyl aryl sulfonate

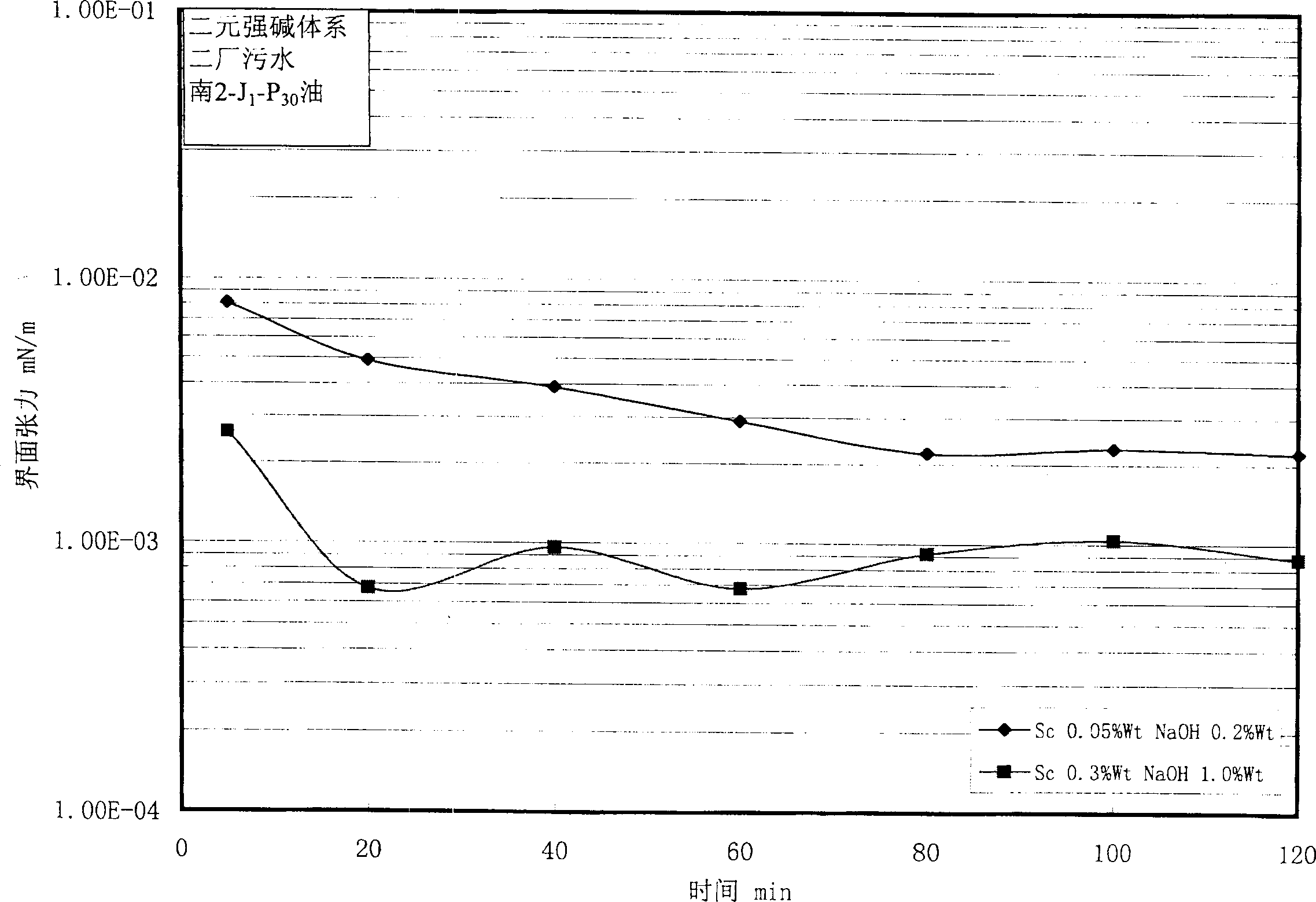

A technology of alkyl aryl sulfonate and alkyl benzene sulfonic acid, applied in the preparation of sulfonate and other directions, can solve the problems of high viscosity of raw material oil, troublesome process, complicated product composition, etc., to simplify the operation process, improve the Application performance, dynamic ultra-low interfacial tension stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

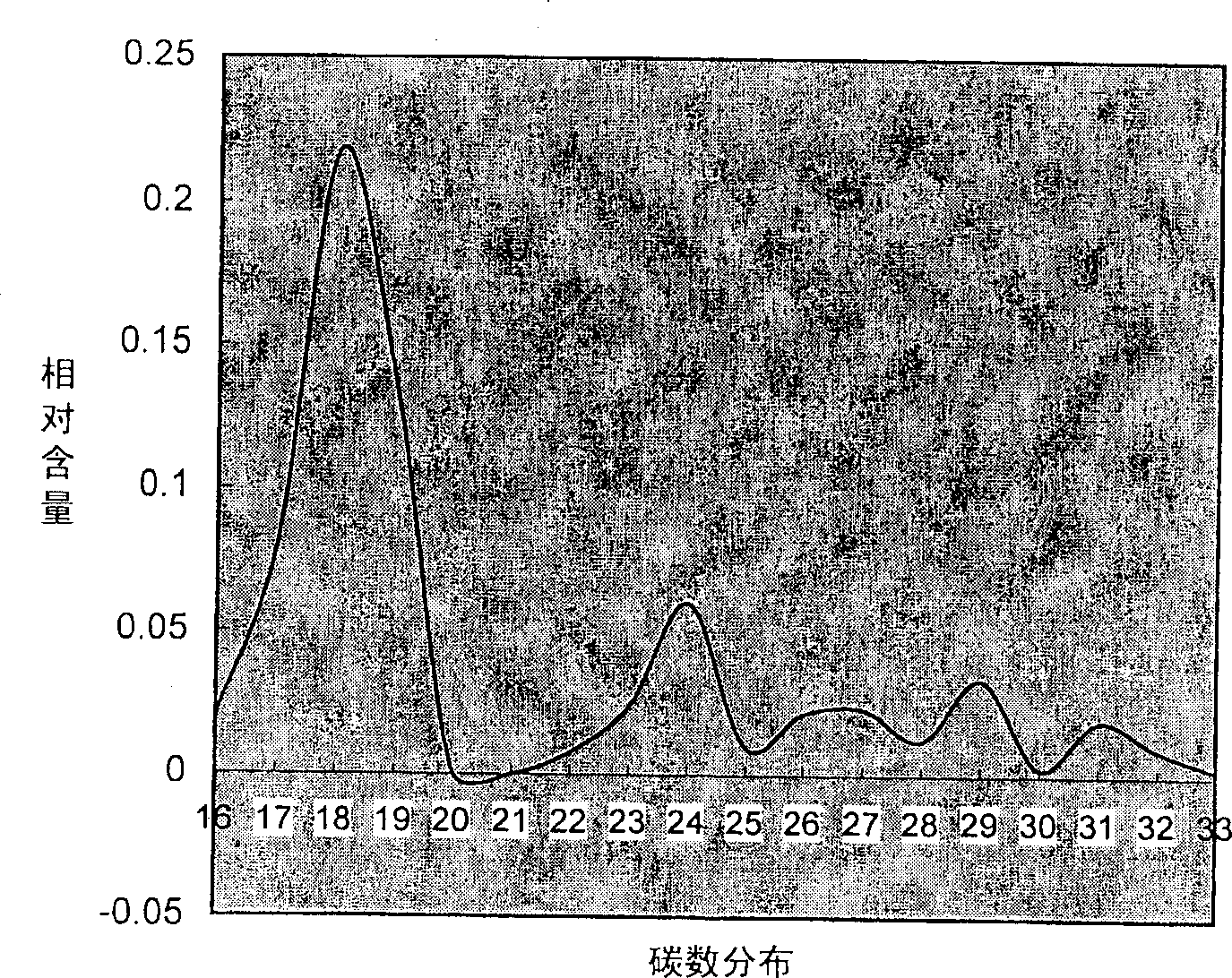

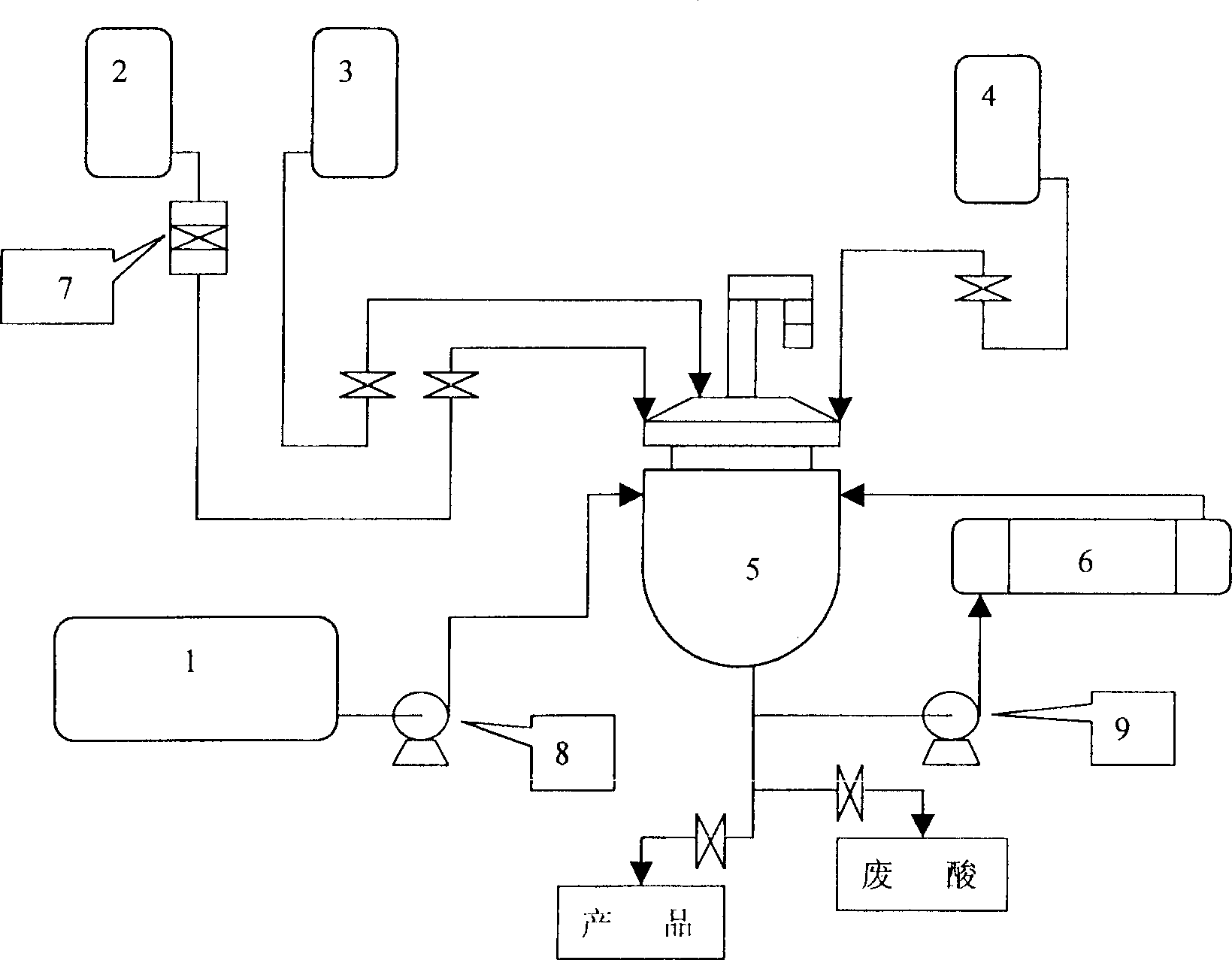

[0038] Mix dodecylbenzene and heavy alkylbenzene in a weight ratio of 3:7, and the spectrogram features after mixing are as follows: figure 1 shown. Sulfonation process such as figure 2 shown. The mixed alkylbenzenes are sent from the storage tank 1 to the enamel reaction kettle 5 through the feed pump 8 . Nicotinic acid enters the reaction kettle 5 from the reaction tank 2 through the nicotinic acid filter 7 . The volume of the reaction kettle is 10 tons, and the ratio of acid to hydrocarbon is 1.1:1. Since sulfonation is an exothermic reaction, the reactants are pumped into the tube-and-tube heat exchanger 6 by the circulation pump 9 to take away the heat. Control the adding speed of oleum so that the temperature in the reactor is around 50°C. Feeding finished, continue to react for half an hour. Then add 15% water of the total weight of the material into the reactor 5 from the head tank 4 through the flow meter, circulate and stir at 60°C for half an hour for hydroly...

Embodiment 2

[0040] Dodecylbenzene and heavy alkylbenzene are mixed at a weight ratio of 2:8, and the weight ratio of oleum to alkylbenzene is 1:1. The spectral characteristics of the raw oil are given by Figure 5 shown. Other conditions and operation method are identical with embodiment 1, obtain product 2#.

Embodiment 3

[0042] The cut material of heavy alkyl benzene is taken, and the spectral features are shown in Figure 6. The weight ratio of oleum to alkylbenzene is 1.2:1. Other conditions and operation method are identical with embodiment 1, obtain product 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com