Bi component paint used as priming lacquer, producing process and usage thereof

A production method and two-component technology, applied in coatings, epoxy resin coatings, polyamide coatings, etc., can solve problems such as not fully satisfying the development of high-tech industries, and achieve bright colors, full paint films, and strong adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composition of the epoxy resin solution of component A is: 5 parts of butanol, 6 parts of cyclohexanone, 12 parts of xylene, 20 parts of epoxy resin, and 2 parts of linear epoxy resin. Wherein the epoxy resin is epoxy resin 601, and the linear epoxy resin is epoxy resin 621, produced by Wuxi Resin Factory.

[0036] Component A is: 2 parts of amino resin, 28 parts of lithopone, 2 parts of talcum powder, 6 parts of precipitated barium sulfate and 30 parts of epoxy resin solution. Wherein the amino resin is amino resin 590-4, produced by Tianjin Resin Factory.

[0037] Component B: 35 parts of polyamide resin T-31, 20 parts of cyclohexanone, 28 parts of xylene, 2 parts of fatty acid aluminum. Among them, polyamide resin T-31 is produced by Tianjin Yanhai Chemical Co., Ltd.

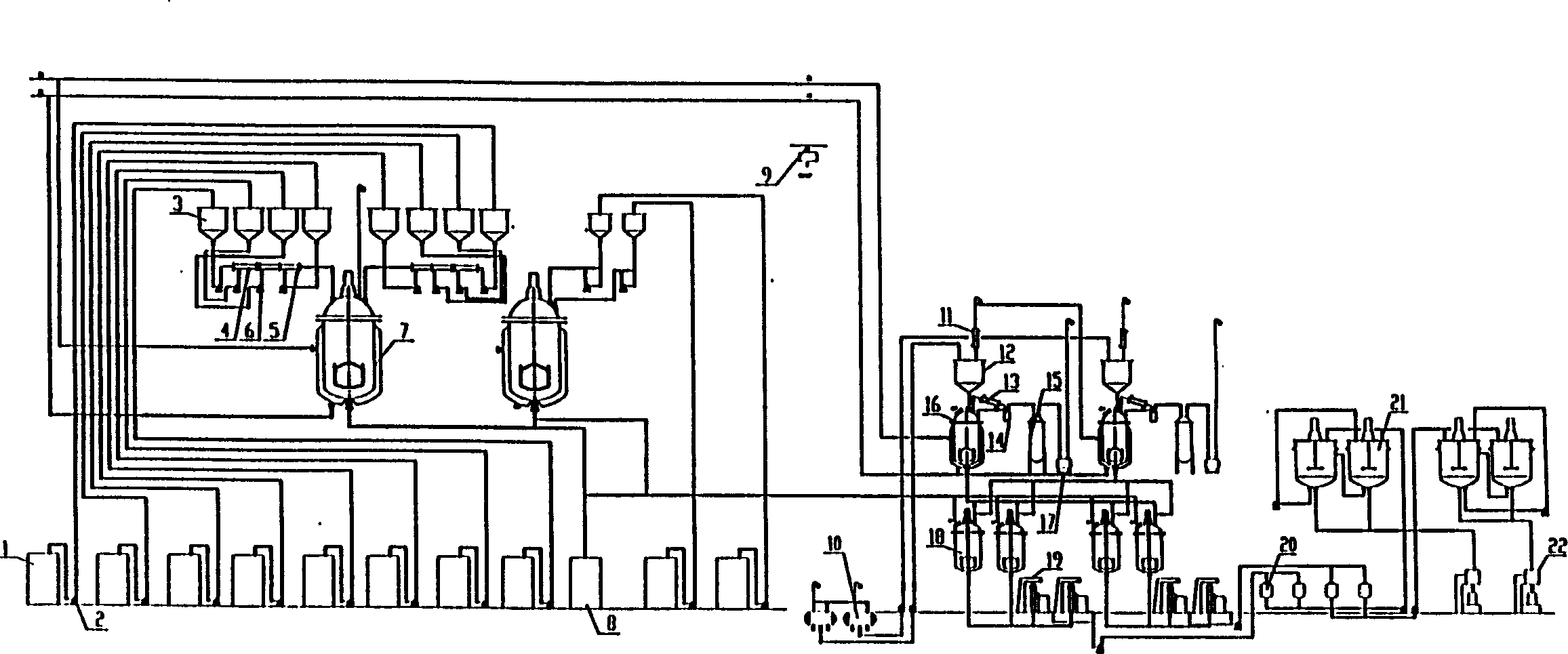

[0038] The production process of component A epoxy resin liquid: first, butanol, cyclohexanone, xylene, epoxy resin, and linear epoxy resin in the raw material barrel 1 are passed through the upp...

Embodiment 2

[0044] Different from Example 1, the raw material ratio of the epoxy resin solution of component A is: 11 parts of butanol, 10 parts of cyclohexanone, 18 parts of xylene, 28 parts of epoxy resin 604, and 28 parts of linear epoxy resin 621 for 8 copies. The stirring speed is 800 rpm, the temperature is gradually raised to 160°C at a rate of 2°C / min, and the gas supply is stopped at 150min.

[0045] The raw material ratio of the finished product of component A is: 3 parts of amino resin, 33 parts of lithopone, 2 parts of talcum powder, 5 parts of precipitated barium sulfate and 36 parts of epoxy resin solution. The stirring speed is 1200 rpm, the stirring time is 40 minutes, and the fineness is 35 microns.

[0046] The raw material ratio of the finished product of component B is: 48 parts of polyamide resin T-31-1, 26 parts of cyclohexanone, 36 parts of xylene, 4 parts of lead rosinate, the stirring speed is 1200 rpm, and the stirring time is 10min.

[0047] When in use, when...

Embodiment 3

[0050] The difference from Example 1 is that the raw material ratio of the epoxy resin solution of component A is: 11 parts of butanol, 8 parts of cyclohexanone, 15 parts of xylene, 30 parts of epoxy resin 6101, and 30 parts of linear epoxy resin 621 for 8 copies. The stirring speed is 800 rpm, the temperature is gradually raised to 160 °C at a rate of 2 °C / min, and the gas supply is stopped at 130 min.

[0051] The raw material ratio of the finished product of component A is: 5 parts of amino resin, 30 parts of lithopone, 4 parts of talcum powder, 5 parts of precipitated barium sulfate and 40 parts of epoxy resin solution. The stirring speed is 1200 rpm, the stirring time is 40 minutes, and the fineness is 35 microns.

[0052] The raw material ratio of the finished component B is: 40 parts of polyamide resin, 23 parts of cyclohexanone, 30 parts of xylene, 2 parts of fatty acid aluminum, the stirring speed is 1150 rpm, and the stirring time is 10 minutes.

[0053] When in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com