Digital printing ink, dyestuff refining method thereof and digital printing method

A technology of digital printing and refining method, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of unseen and unseen food coloring dye raw materials, and achieve bright color, mature production process, and color fastness to soaping Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

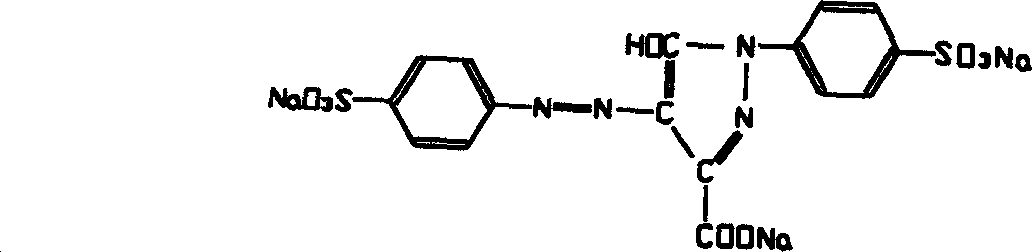

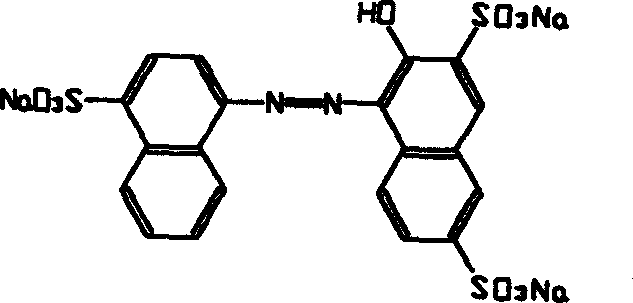

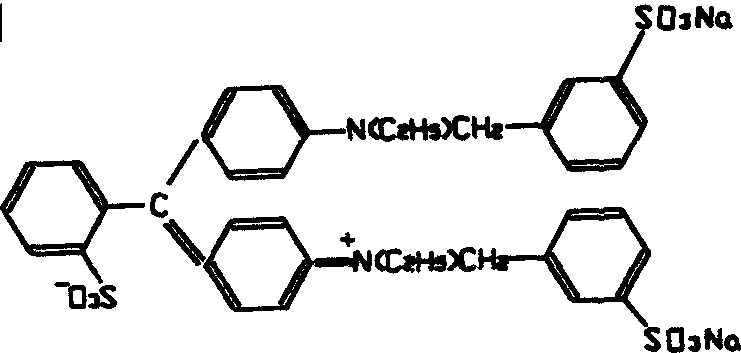

Image

Examples

Embodiment 1

[0033] Embodiment 1: Refining of food coloring and preparation of digital printing ink

[0034] Take food colorings available in the market: amaranth 0.1-0.2kg, lemon yellow 0.1-0.2kg, edible bright blue 0.1-0.2kg, mixed black 0.1-0.2kg, add dimethylformamide solvent to dissolve, filter to remove insoluble matter , the organic solvent is evaporated to obtain refined food coloring. Add 1 kg of wetting agent glycerin; 0-1 kg of ethanol as solubilizer; 0.01-0.1 kg of phenol as preservative, put them into a container, add 10-20 kg of water at normal temperature to dissolve and prepare dye solutions of four colors. The above solution is filtered again with a filter cloth to remove insoluble matter and impurities to obtain digital printing ink.

Embodiment 2

[0035] Embodiment 2: Refining of food coloring and preparation of digital printing ink

[0036] Take commercially available food coloring: amaranth 0.05-0.1kg, tartrazine 0.05-0.1kg, edible bright blue 0.05-0.1kg, mixed black 0.05-0.1kg, respectively add methyl pyrrolidone solvent to dissolve, filter to remove insoluble matter, steam Remove the organic solvent to obtain refined food coloring. Add 1 to 2 kg of wetting agent diethylene glycol and 0 to 1 kg of butanone as a solubilizer for each of them, put them into a container, add 10 to 20 kg of water at normal temperature to dissolve and prepare dye solutions of four colors. The above solution is filtered again with filter paper to remove insoluble matter and impurities to obtain digital printing ink.

Embodiment 3

[0037] Example 3: Fabric Treatment and Digital Printing

[0038]Take the digital printing ink of the above-mentioned embodiment 1 or embodiment 2, and pour it into the four color ink cartridges of the digital printing machine for use.

[0039] Process 10kg woolen fabric, at first be (1) get each 0.1kg of citric acid, urea, sodium sulfate and boric acid, then get starch size (1~4% of the treated fabric weight), use starch 0.1~0.4kg. Mix the above-mentioned components, add 10-20 kg of deionized water, heat and gelatinize, control the acidity PH=3-4 with the addition of citric acid, and make an acidic spraying liquid. (2) Hold up the edge of the wool fabric for uniform spraying. Then (3) step to dry under mild temperature conditions.

[0040] After pretreatment, let the fabric pass through the digital printing machine, and use the ENCAD Nova Jet700 thermal foaming digital printer to start printing the pre-designed pattern. This printing method is well known by the industry.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com