Solid phosphoric acid catalyst and its prepn process

A phosphoric acid catalyst, solid technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of unsatisfactory crushing strength of catalysts, reduce production process, simplify operation process, Requires a loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

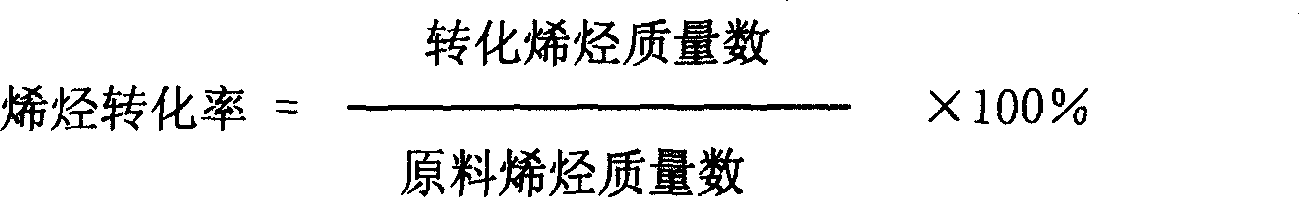

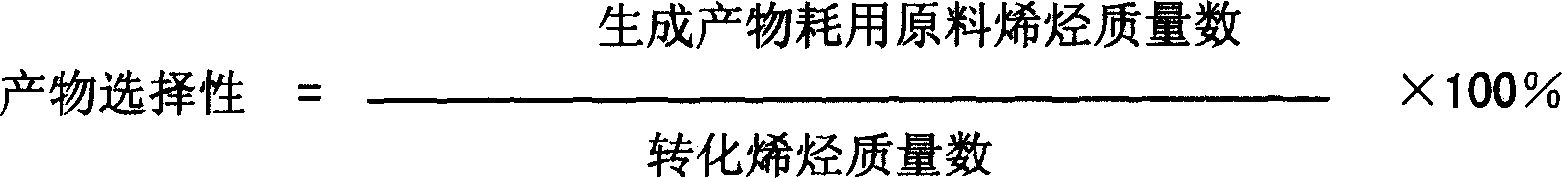

Method used

Image

Examples

Embodiment 1

[0028] Preparation of Catalyst A:

[0029] 700 grams of concentration 83% (in P 2 o 5 (by weight) polyphosphoric acid is placed in a 2000 ml beaker, heated to 100 ° C, under electric stirring, 70 grams of boric acid is added, and reacted for 30 minutes to make polyphosphate; at the same time, 190 grams of dry diatomaceous earth and a certain amount Phosphotungstic acid H 7 P(W 2 o 7 ) 6 ·xH 2 O (x is generally between 9 and 17) is placed in a kneader, mixed evenly, added the polyphosphate prepared by the above reaction, kneaded in the kneader for 5 minutes, and blended evenly to obtain a viscous Paste material, the material is extruded into cylindrical particles of 4×6-8mm, dried at 150°C for 2 hours, roasted at 500°C for 5 hours, cooled naturally to room temperature to obtain a catalyst precursor; then loaded into Ф50 In the stainless steel tubular activation tower of × 1000 millimeters, pass into air and water vapor to carry out activation, air: water vapor molar rati...

Embodiment 2

[0033] Preparation of Catalyst B:

[0034] According to the preparation method of Example 1, the difference: replace 70 grams of boric acid with 47 grams of boron oxide, change the amount of phosphotungstic acid, a certain amount of phosphotungstic acid is made into a 20% (weight) aqueous solution, add to the diatomaceous earth In the kneader, mix homogeneously, the solid phosphoric acid catalyst B that makes consists of:

[0035] Si 1 B 0.5 W 0.15 (P 2 o 5 ) 1.55 ·(H 2 O) 0.8

[0036] According to the aforementioned catalyst evaluation method, catalyst B was used for butene-2 oligomerization reaction, and the evaluation process conditions were: reaction temperature 180 ° C, pressure 5.0 MPa, liquid volume space velocity 2.0 hours -1 , the raw material butene-2 concentration is 82.8% (mass). Catalyst evaluation results: the average conversion rate of butene-2 is 84.0%, and the selectivity of octene is 88.5%.

Embodiment 3

[0038] Preparation of Catalyst C:

[0039] According to the preparation method of Example 1, the difference: replace boric acid with magnesium oxide, use silicotungstic acid (H 4 SiW 12 o 40 ·7H 2 O) instead of phosphotungstic acid, the obtained solid phosphoric acid catalyst C consists of:

[0040] Si 1 Mg 0.2 W 0.10 (P 2 o 5 ) 1.55 ·(H 2 O) 0.8

[0041] The catalyst was evaluated according to the evaluation method in Example 1, and the evaluation results of the catalyst were: the average conversion rate of propylene was 80.8%, and the selectivity of propylene oligomers was 83.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com