Recovery method of heavily polluted substance produced in ADC foaming agent production process and its device

An ADC foaming agent and production process technology, which is applied in the field of recycling solid matter, can solve serious pollution and other problems, and achieve the effects of low equipment investment, good economic and social benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

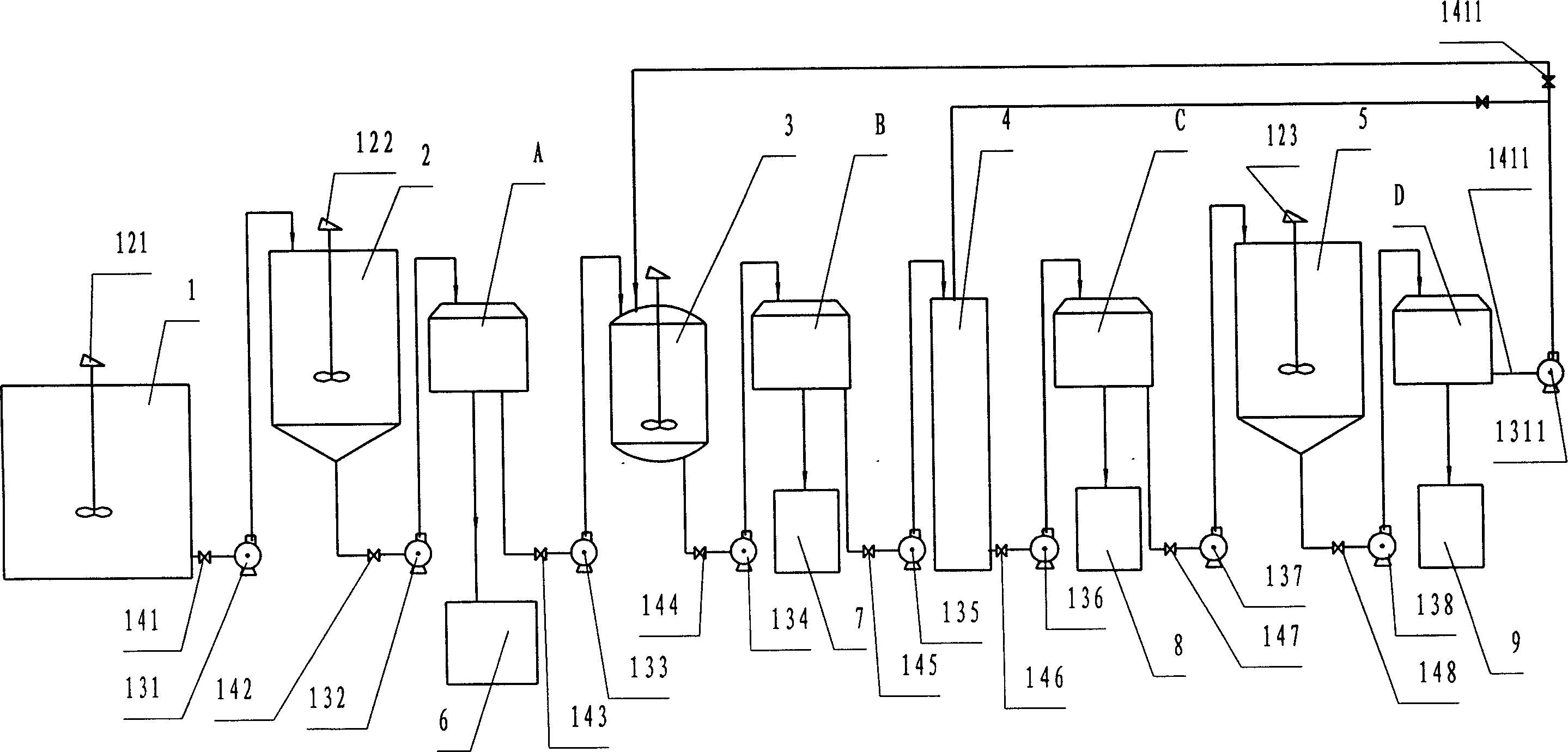

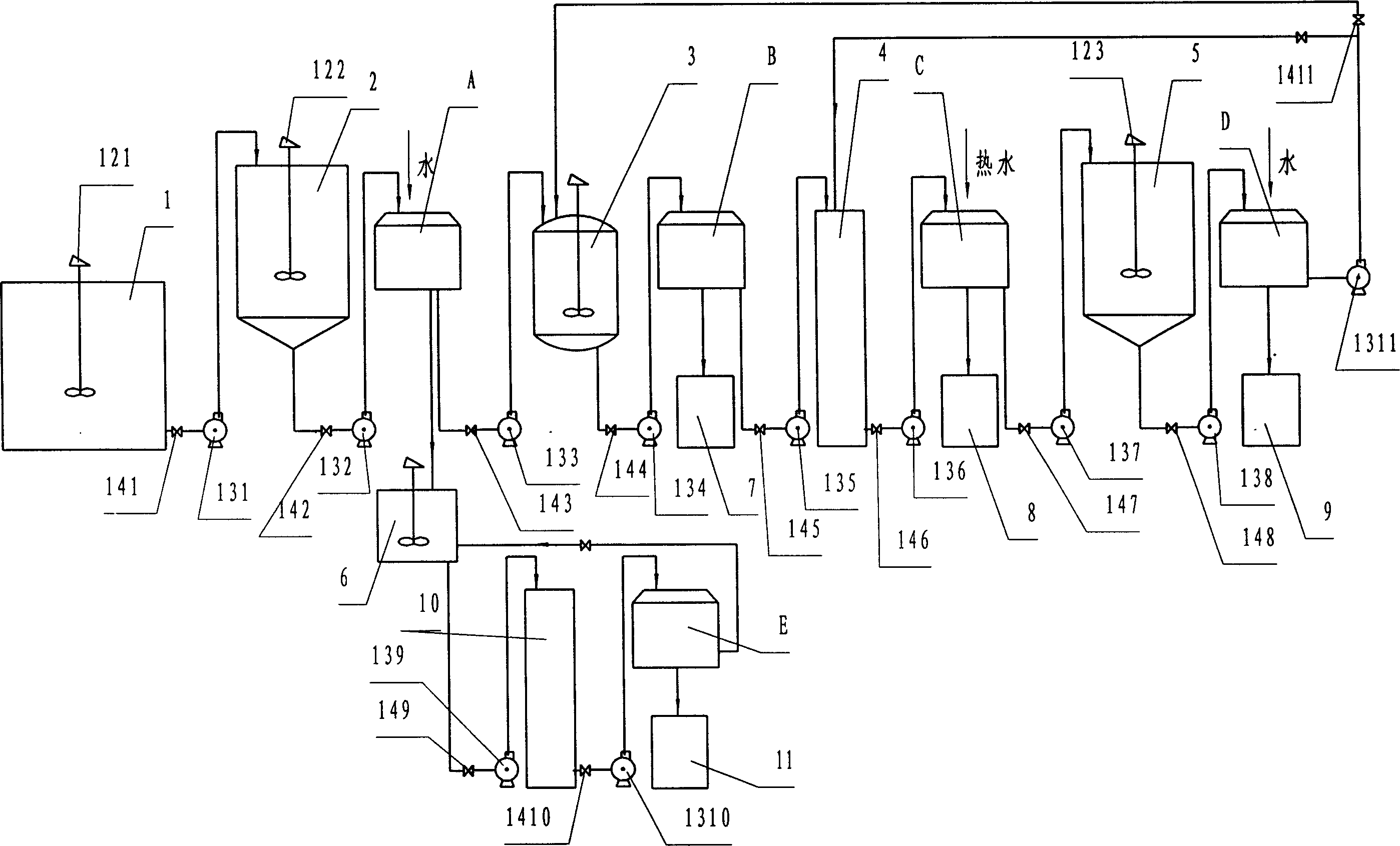

[0122] Such as figure 2 The recovery device for serious pollutants in the production process of ADC blowing agent shown includes equipment such as: neutralizing hydrazine metering tank 1, freezing pot 2, centrifuge A, condensation pot 3, centrifuge B, evaporation tank 4, centrifuge C, the second freezing pot 5, centrifuge D, Glauber's salt storage tank 6, biurea storage tank 7, sodium chloride storage tank 8, ammonium chloride storage tank 9, second evaporation tank 10, centrifuge E, drying Furnace 11, agitator 12, feed pump 13 and valve 14.

[0123] The connection mode of these equipments is as follows: neutralizing hydrazine metering tank 1 is equipped with stirrer 121, is communicated with freezing pot 2 by feeding pump 131 and valve 141, and freezing pot 2 is equipped with stirrer 122, is connected with centrifuge by pump 132 and valve 142 A is connected, the solid discharge port of centrifuge A is connected with Glauber's salt storage tank 6, the filtrate discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com