Method of producing large quantity thick wall spore by thick wall spore verticillium liquid fermentation

A liquid fermentation and chlamydospore technology, applied in the field of mycology, can solve the problems of small production scale, difficult to realize industrialization, etc., and achieve the effect of great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

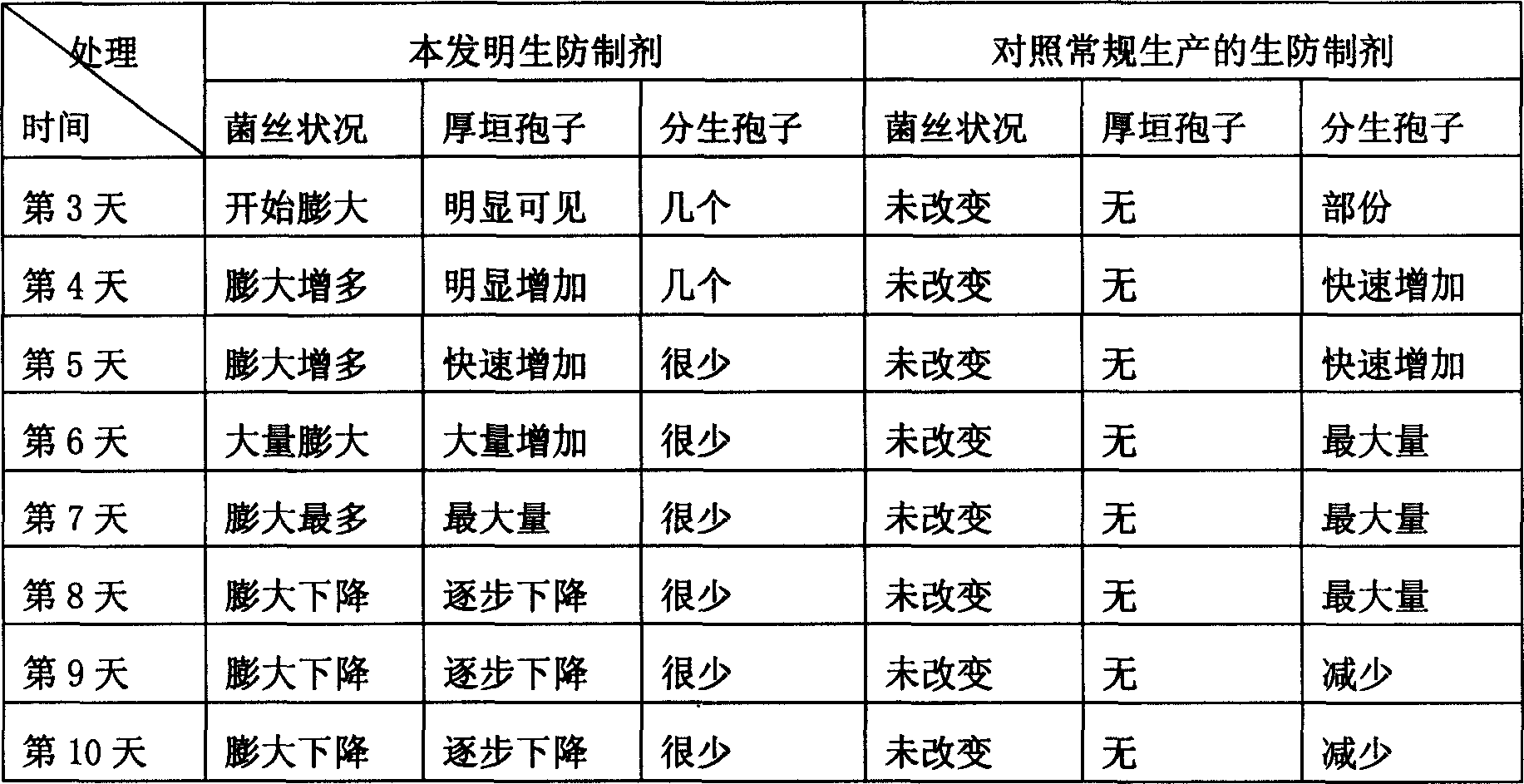

Examples

Embodiment 1

[0022] 1. Preparation of solid strains

[0023] Mix 100 grams of sweet potato powder, 75 grams of corn flour, 150 grams of bran, 150 grams of corncob, 5 grams of superphosphate, 5 grams of calcium carbonate, and 15 grams of bean cake powder, then add water to make the water 60%. Mix it with 40-mesh fine sand at a ratio of 1:0.2 (volume ratio), put it into a conical flask and sterilize it at 120°C for 40 minutes, then insert the cultured test tube species V.chlamydosporium ZK7, and cultivate it at 22°C for 18 days to obtain Solid bacteria.

[0024] 2. Inhibitor preparation (prepare 100 parts of inhibitor according to 10000 milliliters of culture medium)

[0025] 250 mg of 40% thiophanate-methyl, 450 mg of 50% carbendazim, and 1,000 mg of sodium diatomate, mixed well before use.

[0026] 3. Prepare the biocontrol agent of the present invention

[0027] Add 120 grams of molasses, 30 grams of ammonium sulfate, 40 grams of sodium chloride, 10 grams of potassium dihydrogen sulfat...

Embodiment 2

[0036] 1. The preparation of solid strains is the same as in Example 1.

[0037] 2. Inhibitor preparation (preparation of 100 parts of inhibitor according to 10000 milliliters of culture medium)

[0038] 100 mg of 40% thiophanate-methyl, 200 mg of 50% carbendazim, and 500 mg of sodium diatomate, mixed well before use.

[0039] 3. Prepare the biocontrol agent of the present invention

[0040] Add 120 grams of molasses, 30 grams of ammonium sulfate, 40 grams of sodium chloride, 10 grams of potassium dihydrogen sulfate, 20 grams of trisodium citrate, 80 grams of sucrose, and 80 milliliters of glycerin in 10000 milliliters of PDA. Then add the inhibitor formulated in the above 2, in the same way as in Example 1, culture after sterilization and inoculation, and observe the formation of chlamydospores by microscopic examination.

[0041] In addition, 500 milliliters of culture medium was prepared by using the above-mentioned liquid culture medium formula, and no inhibitor was adde...

Embodiment 3

[0045] 1, the preparation of solid strains is the same as in Example 1

[0046] 2. Inhibitor preparation (preparation of 100 parts of inhibitor according to 10000 milliliters of culture medium)

[0047] 400 mg of 40% thiophanate-methyl, 600 mg of 50% carbendazim, and 1500 mg of sodium diatomate, mixed well before use.

[0048] 3. Prepare the biocontrol agent of the present invention

[0049] Add 120 grams of molasses, 30 grams of ammonium sulfate, 40 grams of sodium chloride, 10 grams of potassium dihydrogen sulfate, 20 grams of trisodium citrate, 80 grams of sucrose, and 80 milliliters of glycerin in 10000 milliliters of PDA. Then add the inhibitor formulated in the above 2, in the same way as in Example 1, culture after sterilization and inoculation, and observe the formation of chlamydospores by microscopic examination.

[0050] In addition, 500 milliliters of culture medium was prepared by using the above-mentioned liquid culture medium formula, and no inhibitor was adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com