Preparation process of meta-cresol

A preparation process, the technology of cresol, applied in the field of m-cresol preparation process, can solve the problems of high cost, cumbersome process route, and difficult to solve raw materials, and achieve the effect of low cost, no three waste pollution, and stable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

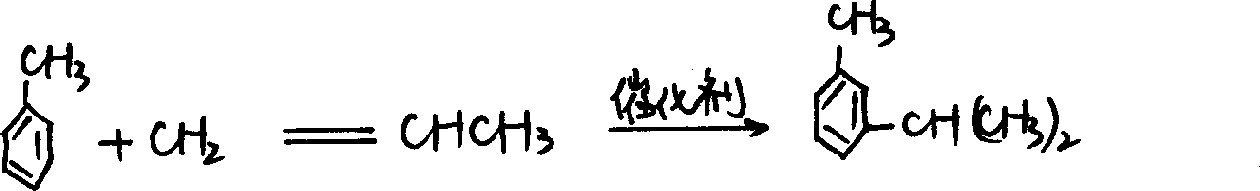

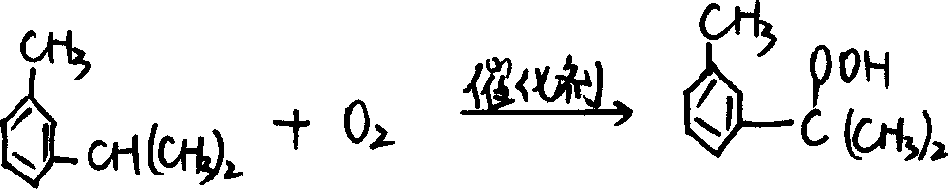

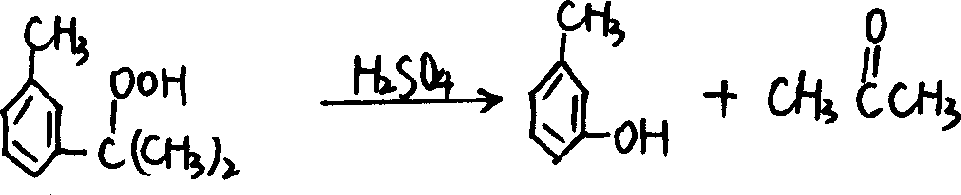

Method used

Image

Examples

Embodiment Construction

[0050] A preparation process of m-cresol has the following technical process:

[0051] A. Salt

[0052] In the salt-forming pot with a cooling jacket, under stirring, first add 3100L of water, then slowly add 1000L of concentrated sulfuric acid, so that the temperature of the material liquid does not exceed 60°C, after the addition, cool down to below 40°C, and add 713Kg of methane Aniline reacts to form an aqueous solution of m-toluidine sulfate.

[0053]

[0054] B. Diazotization

[0055]In the diazotization pot with cooling device, add the m-toluidine sulfate solution in the salt-forming pot at one time, cool down to -5°C, and slowly add about 1200L of 40% sodium nitrite solution to make it react to form m-toluidine Aniline diazonium salt, until it turns blue with potassium iodide starch test paper, stop adding. If it is excessive, use sulfamic acid to remove excess sodium nitrite, and then add a certain amount of dilution water to complete the reaction.

[0056]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com