Stretchable leather-like sheet substrate and process for producing same

A sheet and leather technology, applied in the manufacture of rayon, non-woven fabrics, household appliances, etc., can solve the problems of fiber sticking, hindering the elasticity of polyurethane, and insufficient effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

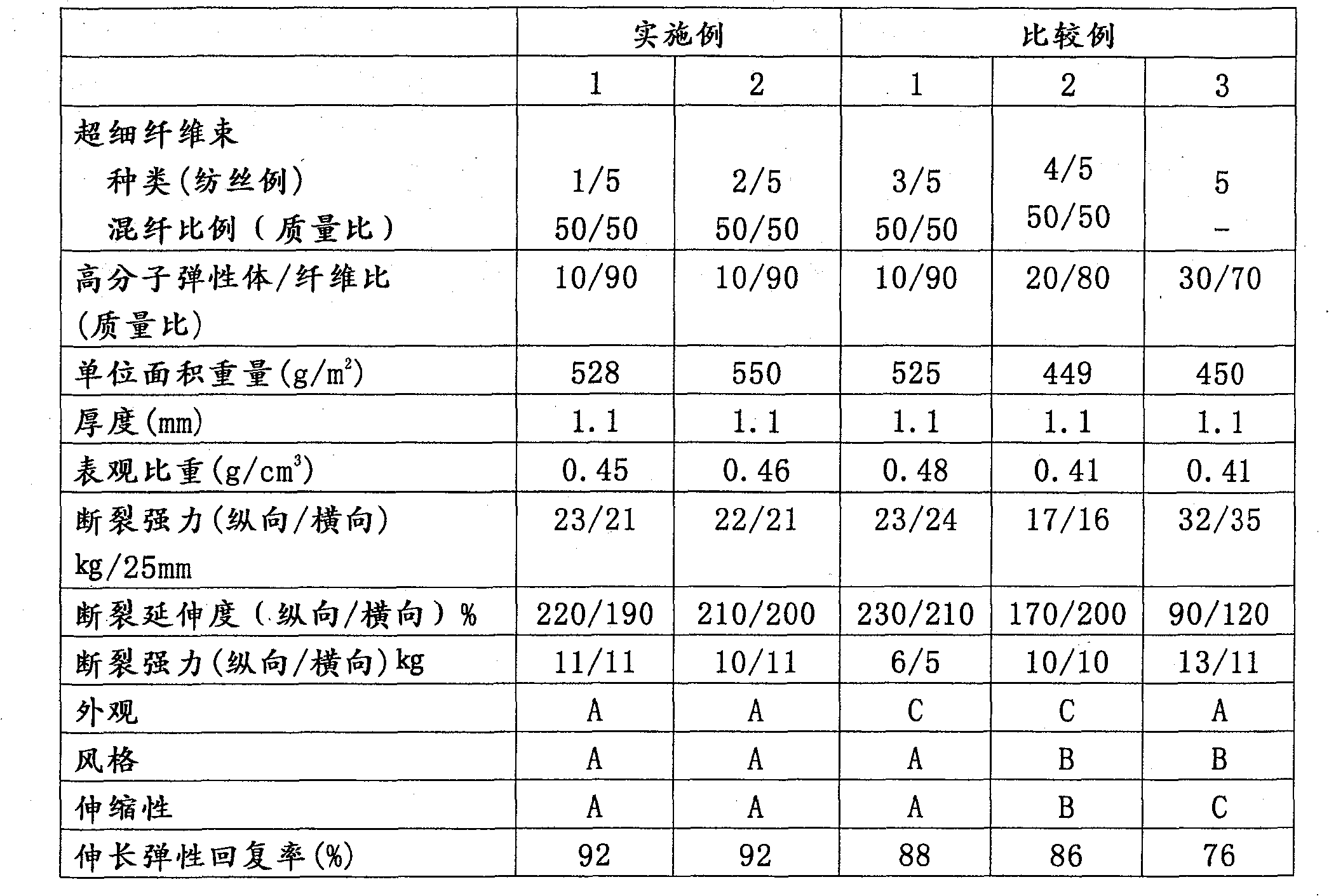

Embodiment 1

[0098] The short fibers obtained in spinning example 1 and spinning example 5 are mixed with a mass ratio of 50 / 50 by a fiber blending machine, and then formed into 260 g / m by cross-overlapping. 2 cotton net. Then, the two sides are combined, about 2500 stitches / cm 2 Acupuncture in bundles. Subsequently, it was shrunk in hot water at 90°C, then heated and dried at 130°C, and squeezed directly with rolls to produce a complex non-woven fabric with a smooth surface. The weight per unit area of the complex non-woven fabric is 535g / m 2 , the apparent specific gravity is 0.48g / cm 3 . A polymeric elastomer obtained by impregnating polyurethane emulsion (Bondik NSA: manufactured by Dainippon Ink Chemical Industry Co., Ltd.), drying and coagulating the complexed nonwoven fabric, and then extracting and removing polyethylene in a hot toluene solution. The mass ratio of fiber / fiber is 10 / 90, and the weight per unit area is 498g / m 2 , the apparent specific gravity is 0.45g / cm 3 ,...

Embodiment 2

[0100] An entangled nonwoven fabric was obtained in the same manner as in Example 1 except that the short fibers obtained in Spinning Example 2 and Spinning Example 5 were used. The weight per unit area of complex non-woven fabric is 550g / m 2 , the apparent specific gravity is 0.46g / cm 3 . This entangled non-woven fabric is processed in the same manner as in Example 1, and the mass ratio that obtains polymer elastomer / fiber is 10 / 90, and the weight per unit area is 504g / m 2 , the apparent specific gravity is 0.46g / cm 3 , a leather-like sheet substrate with a thickness of 1.1 mm. In the ultrafine fiber bundle of the ultrafine fiber as-spun fiber in spinning example 2, it can be observed that there are powdery substances in some places between the ultrafine fibers, which hinders the generation of glue, and the part where there is no powdery substance produces ultrafine fibers. The parts between each other are glued, so that the leather-like sheet matrix has sufficient mech...

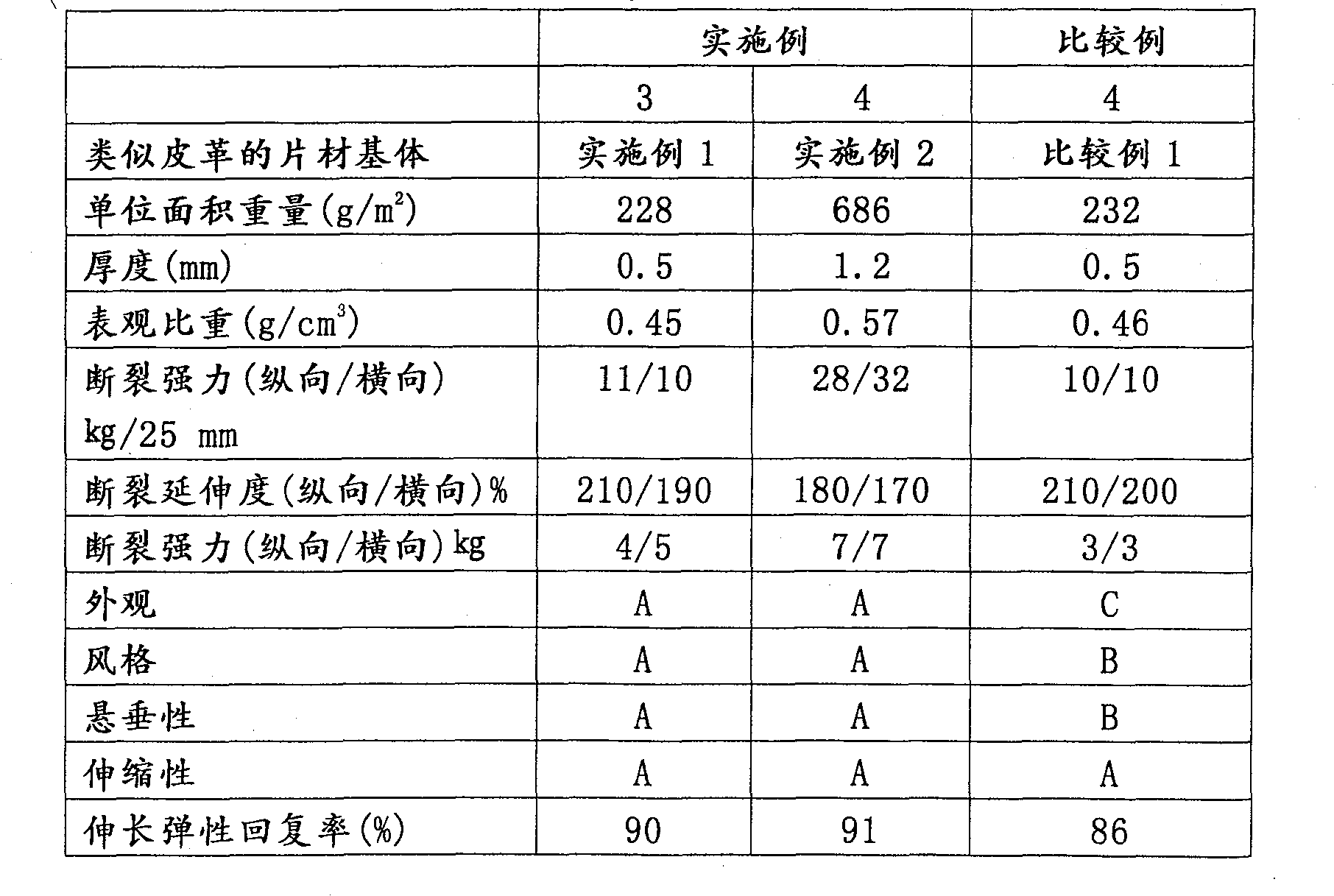

Embodiment 3

[0108] The sheet-like substrate obtained in Example 1 was cut parallel to the surface to obtain a thin body of a leather-like sheet with a thickness of 0.5 mm. The surface opposite to the cut surface was polished and fluffed with 400-grit sandpaper, and then dyed under the following dyeing conditions to obtain a leather-like appearance with a high texture and dense appearance without the adhesion of polyurethane microfibers that make up the fluff on the surface. The sheet material has good stretchability and drapability in both vertical and horizontal directions.

[0109] staining conditions

[0110] Dyeing: rope dyeing machine 90°C×40 minutes

[0111] Dye: Iralan Brown 2GL (Chibagaigi-manufactured) 1% owf

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com