Method for producing a bipolar transistor comprising a polysilicon emitter

A bipolar transistor, polysilicon technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of nitride barrier, inability to use the emitter window, filling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

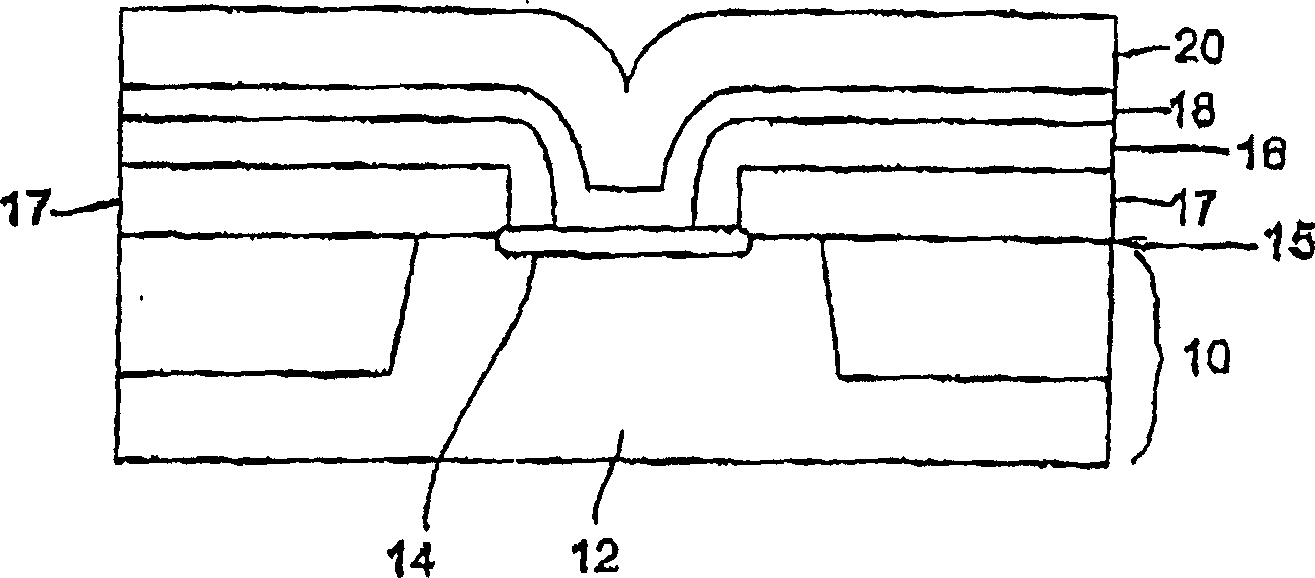

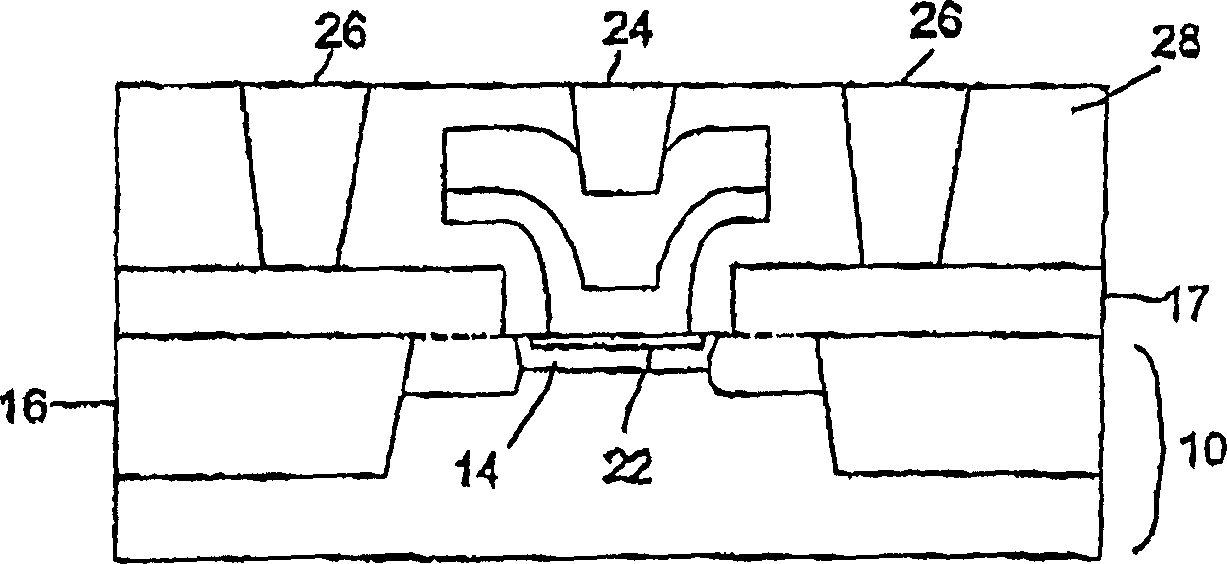

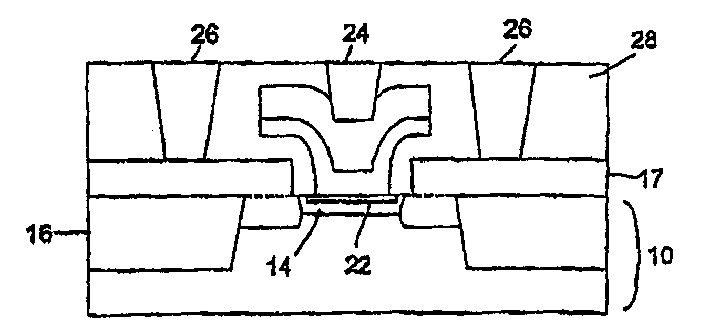

[0021] by figure 1 and figure 2 For reference, a preferred embodiment of the present invention for manufacturing bipolar transistors with polysilicon emitters will be explained in more detail.

[0022] Such as figure 1 As shown, preferably a monocrystalline silicon body is used as a substrate 10 for the bipolar transistor. In the substrate 10, a first region 12 of a first conductivity type is formed, which region 12 will later serve as a collector region. In the substrate 10 a further region 14 of a second conductivity type is formed, which then serves as a base region 14 .

[0023] In relation to the present case, the first conductivity type is denoted as so-called n-doped, while the second conductivity type is denoted as so-called p-doped, if the doping in the semiconductor material is in which the predominant charge carriers When the system is electrons, it is n-type, and the doping in the semiconductor material is p-type if the main charge carrier system is holes. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com