Polycarbonitride-based copolymer as well as preparation method and application thereof

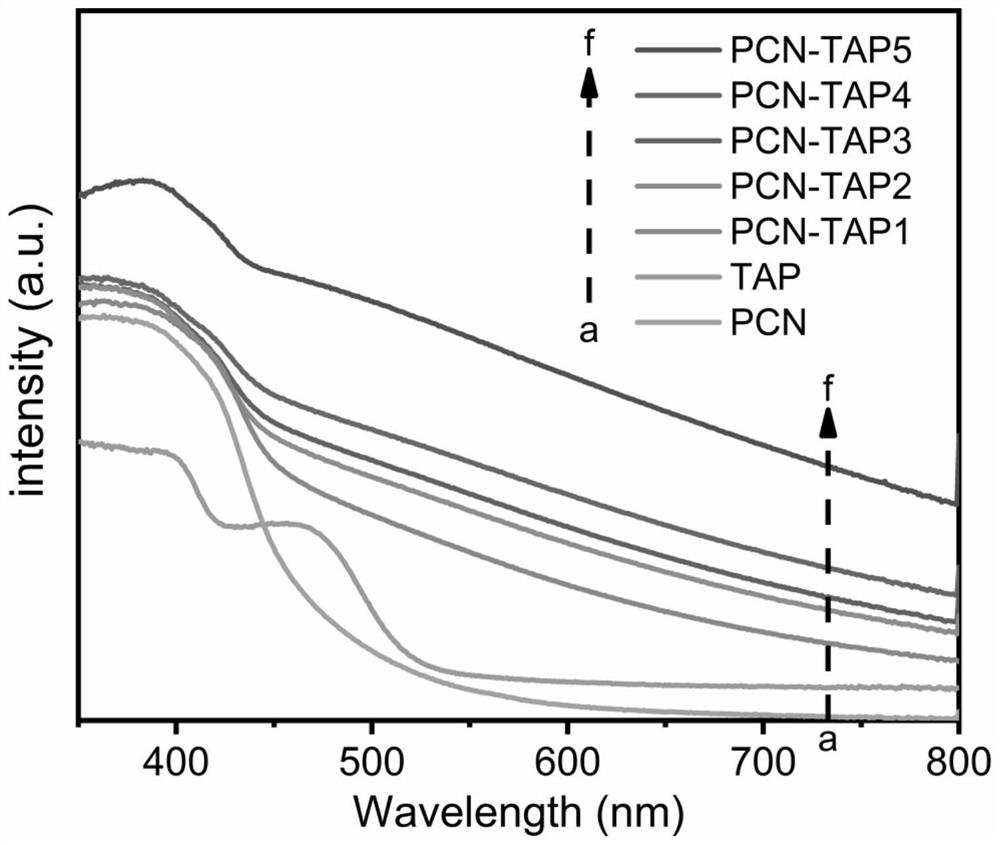

A technology of polycarbonitride and polycarbonitride chains, applied in the field of copolymers, can solve the problems of insufficient light absorption range and fast recombination, and achieve excellent electronic characteristics, high separation efficiency and good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The present invention also provides the preparation method of the above-mentioned polycarbonate-based copolymer, comprising the steps of:

[0078] Place the monomer for preparing the polycarbonitride segment in a protective gas atmosphere, and react at 400°C to 450°C to prepare a precursor;

[0079] Mix the precursor and the monomers for preparing the polyarylamine segment, place it in a protective gas atmosphere, and carry out a copolymerization reaction at 500°C to 600°C to prepare the polycarbonitride-based copolymerization things.

[0080] The polycarbonate-based copolymer is prepared by heat treatment, and the operation is simple and the production efficiency is high.

[0081] In one embodiment, the mass ratio of the monomers used to prepare the polycarbonitride segment to the monomer used to prepare the polyarylamine segment is (120-6000):1.

[0082] In one embodiment, after mixing the precursor and the segmented monomers for preparing the polyarylamine, the res...

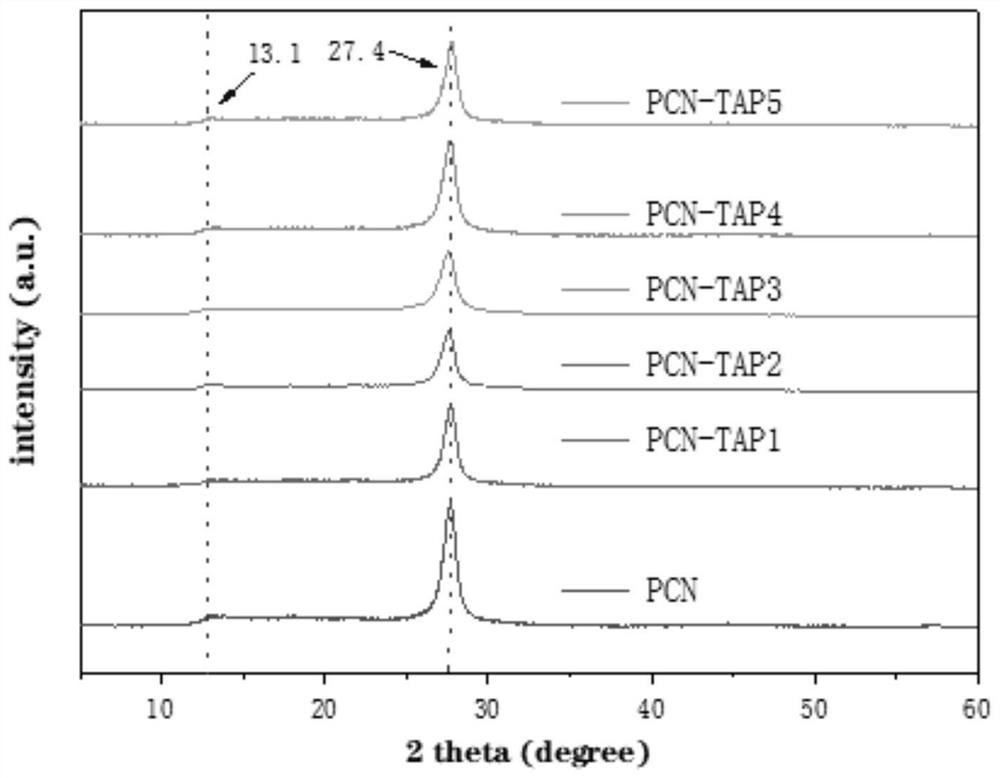

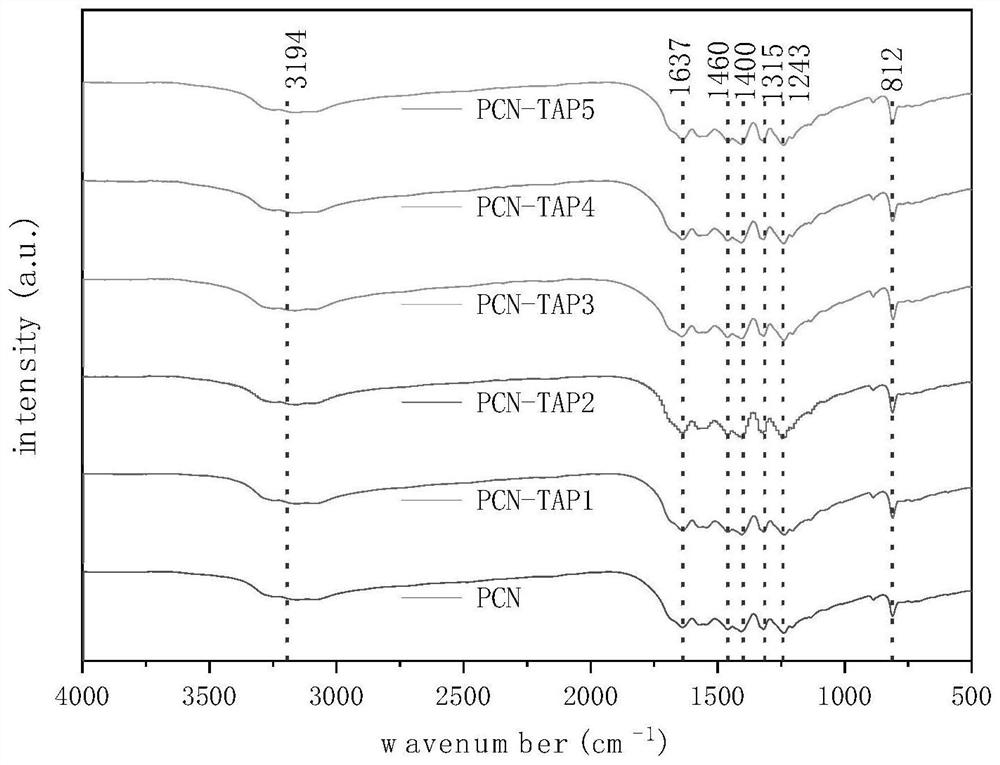

Embodiment 1

[0091] (1) Put 5 g of melamine in a covered crucible, then place it in a muffle furnace, and raise the temperature to 420 °C at a rate of 2 °C / min under an argon atmosphere, keep the temperature for 4 hours, and then naturally cool to room temperature , to obtain melem, which is white in shape.

[0092] (2) Put 3 g of melem and 1 mg of TAP in a mortar, then add 6 mL of ethanol to infiltrate and grind for a certain period of time, and then place it in a vacuum oven at 60° C. for 10 h.

[0093] (3) Place the dried sample in step (2) in a covered crucible, then place it in a muffle furnace, and raise the temperature to 550°C at a heating rate of 2°C / min under an argon atmosphere. After 6 hours, it was naturally cooled to room temperature to obtain PCN-TAP1 with a light brown color.

Embodiment 2

[0095] (1) Put 5 g of melamine in a covered crucible, then place it in a muffle furnace, and raise the temperature to 420 °C at a rate of 2 °C / min under an argon atmosphere, keep the temperature for 4 hours, and then naturally cool to room temperature , to obtain melem, which is white in shape.

[0096] (2) Put 3g of melem and 10mg of TAP in a mortar, then add 6mL of ethanol to infiltrate and grind for a certain period of time, and then put it in a vacuum oven at 60°C for 10h.

[0097] (3) Place the dried sample in step (2) in a covered crucible, then place it in a muffle furnace, and raise the temperature to 550°C at a heating rate of 2°C / min under an argon atmosphere. 6h, and then naturally cooled to room temperature to obtain PCN-TAP2 with a light brown color.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com