Peanut bran-based supercapacitor electrode material and preparation method and application thereof

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of unfriendly electrode material sources, unfavorable industrial production, and low specific capacitance, so as to improve electrochemical performance , easy access, and the effect of expanding the space between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Rinse the peanut bran five times with distilled water, and dry it in an oven at 90°C for 24 hours.

[0038] 2. Crush the peanut bran into fine particles, pass through a 200-mesh sieve, place in a blast drying oven, and dry at 100°C for 24 hours to obtain peanut bran powder.

[0039] 3. Mix the above-mentioned peanut bran powder with KOH and urea at a mass ratio of 1:1:1, add distilled water and stir for 24 hours, and dry the mixture completely at 80°C.

[0040] 4. Using a tube furnace, the dried mixture was heat-treated at 800° C. for 2 h in an argon atmosphere with a heating rate of 4° C. / min, and cooled naturally to room temperature to obtain a black product.

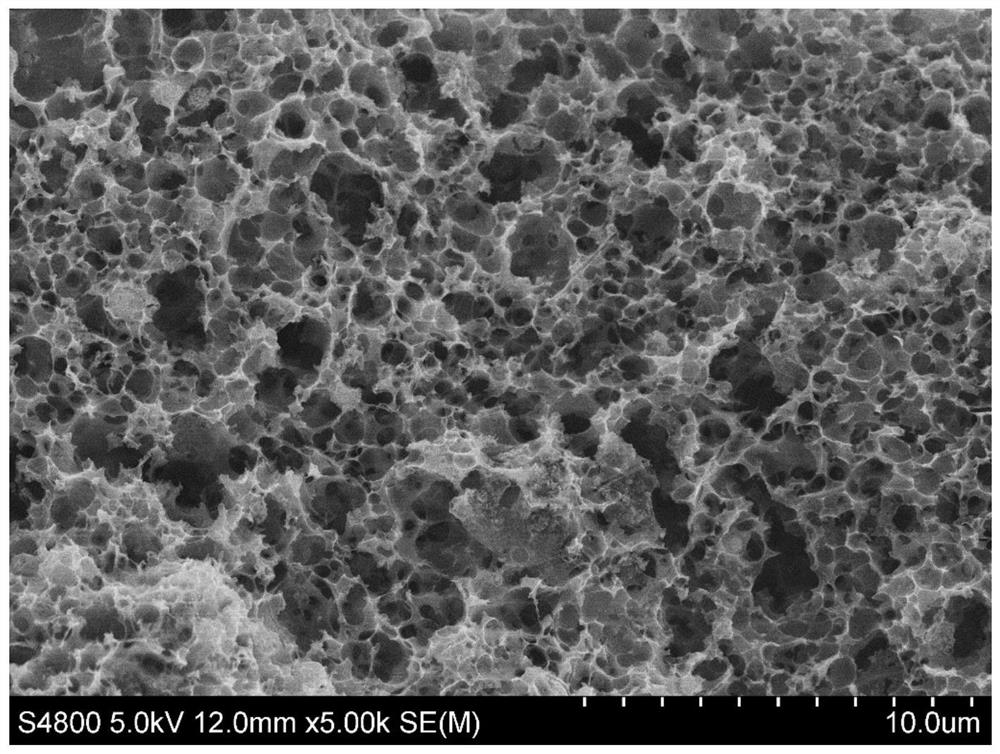

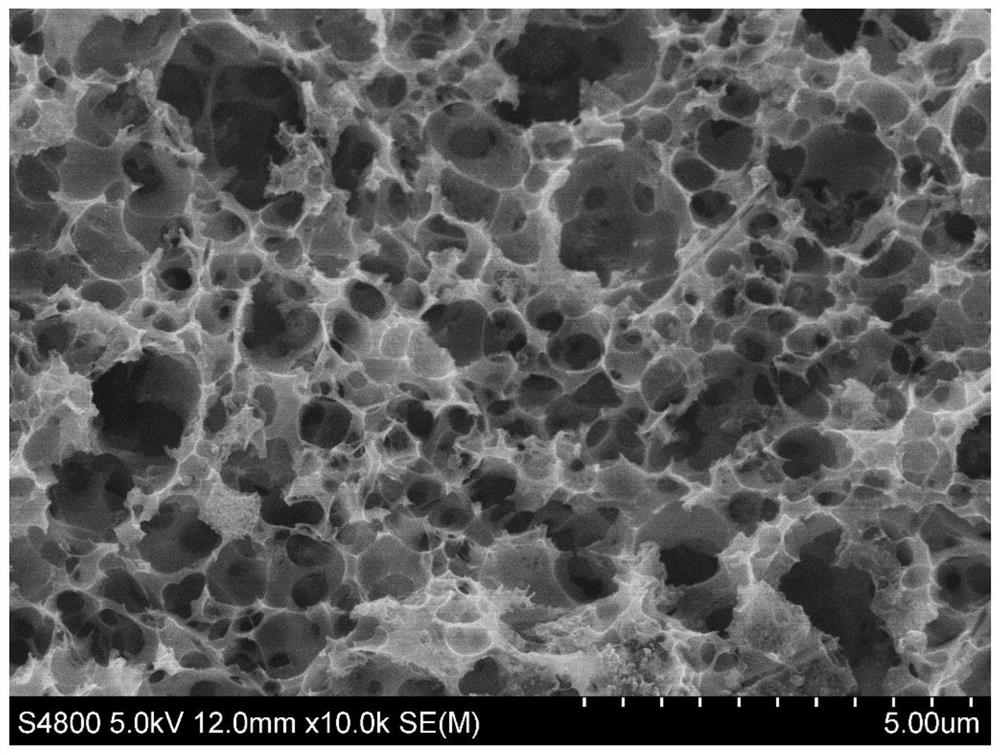

[0041] 5. The product was washed with 1M HCl until no bubbles were generated, and then washed with distilled water until neutral pH=7. The cleaned sample was vacuum dried at 60° C. to obtain the target porous carbon material.

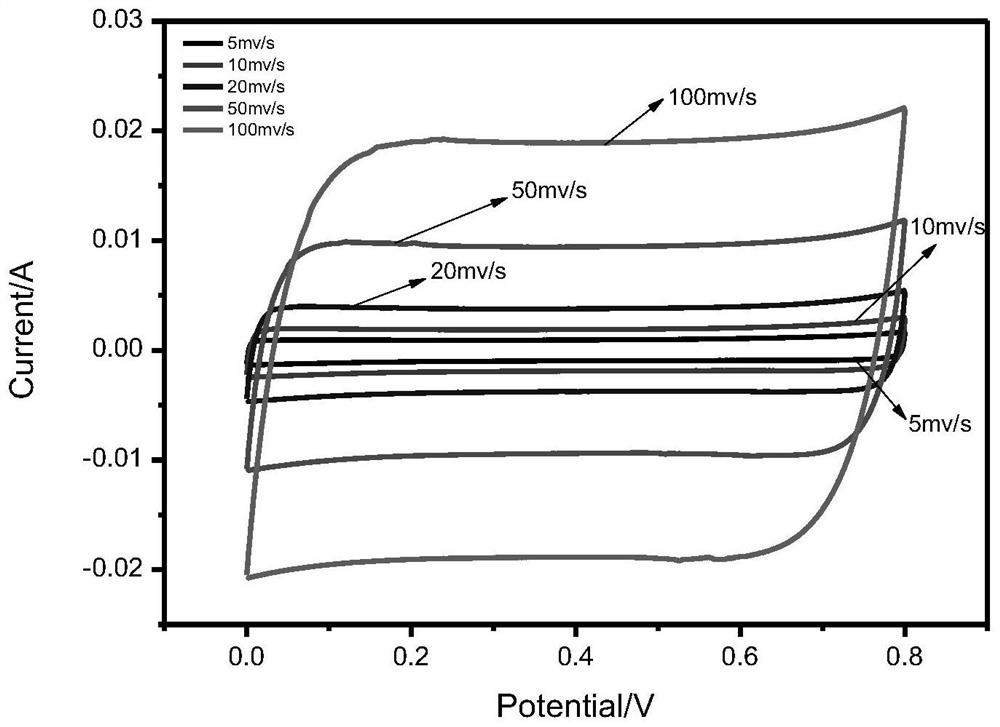

[0042] 6. Making electrodes: Grind the porous carbon material (active material)...

Embodiment 2

[0057] 1. Rinse the peanut bran with distilled water 8 times, put it in an oven and dry it at 110°C for 36 hours.

[0058] 2. Crush peanut bran into fine particles, pass through a 200-mesh sieve, place in a blast drying oven, and dry at 80°C for 24 hours to obtain peanut bran powder.

[0059] 3. Take the above-mentioned peanut bran powder sample and mix it with KOH and urea at a mass ratio of 1:1.5:1, add distilled water and stir for 24 hours, and dry the mixture completely at 80°C.

[0060] 4. Using a tube furnace, the dried sample was heat-treated at 800°C for 2 hours in an argon atmosphere, the heating rate was 4°C / min, and cooled naturally to room temperature to obtain a black product.

[0061] 5. The product was washed with 1M HCl until no bubbles were generated, and then washed with distilled water until neutral pH=7. The cleaned sample was vacuum dried at 60° C. to obtain the target porous carbon material.

Embodiment 3

[0063] 1. Rinse the peanut bran 7 times with distilled water, and dry it in an oven at 100°C for 36 hours.

[0064] 2. Crush peanut bran into fine particles, pass through a 200-mesh sieve, place in a forced air drying oven, and dry at 100°C for 36 hours to obtain peanut bran powder.

[0065] 3. Mix the above-mentioned peanut bran powder with KOH and urea at a mass ratio of 1:2:1, add distilled water and stir for 24 hours, and dry the mixture completely at 80°C.

[0066] 4. Using a tube furnace, the dried mixture was heat-treated at 800° C. for 2 h in an argon atmosphere with a heating rate of 4° C. / min, and cooled naturally to room temperature to obtain a black product.

[0067] 5. The product was washed with 1M HCl until no bubbles were generated, and then washed with distilled water until neutral pH=7. The cleaned sample was vacuum dried at 60° C. to obtain the target porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com