Activated iron electrode

An iron electrode, activation type technology, applied in the field of electrodes, can solve the problems of low electrode charging efficiency, limited battery specific energy, limited application field, etc., and achieve the effects of inhibiting the self-discharge of iron, simple manufacturing process, and prolonging shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

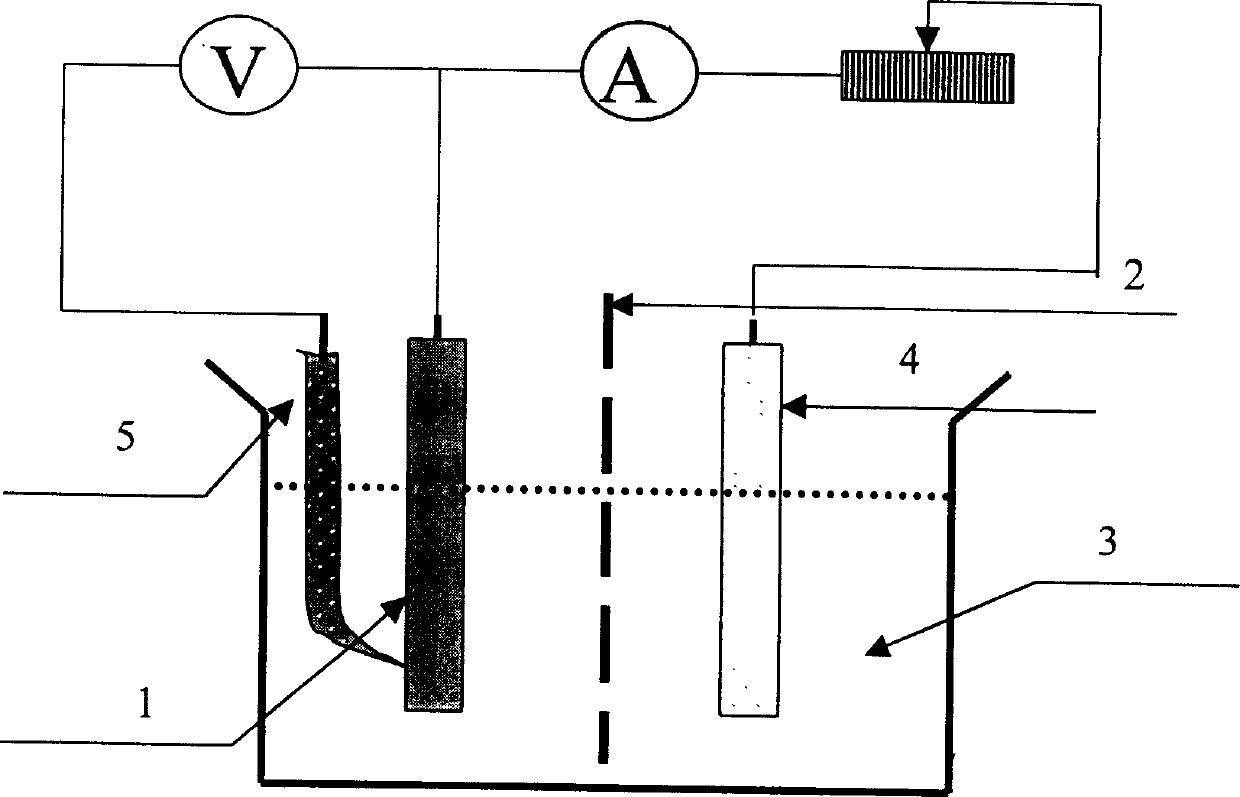

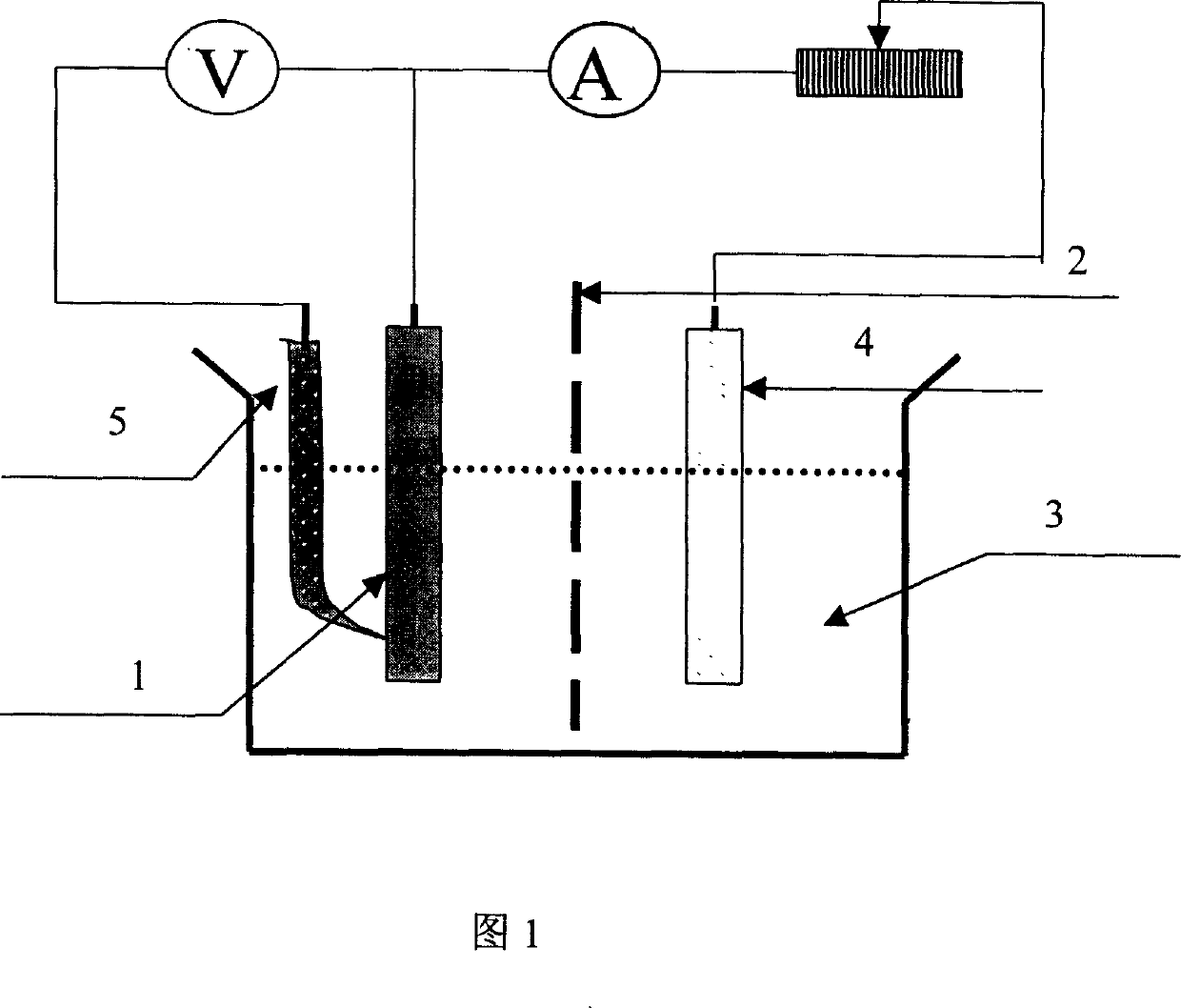

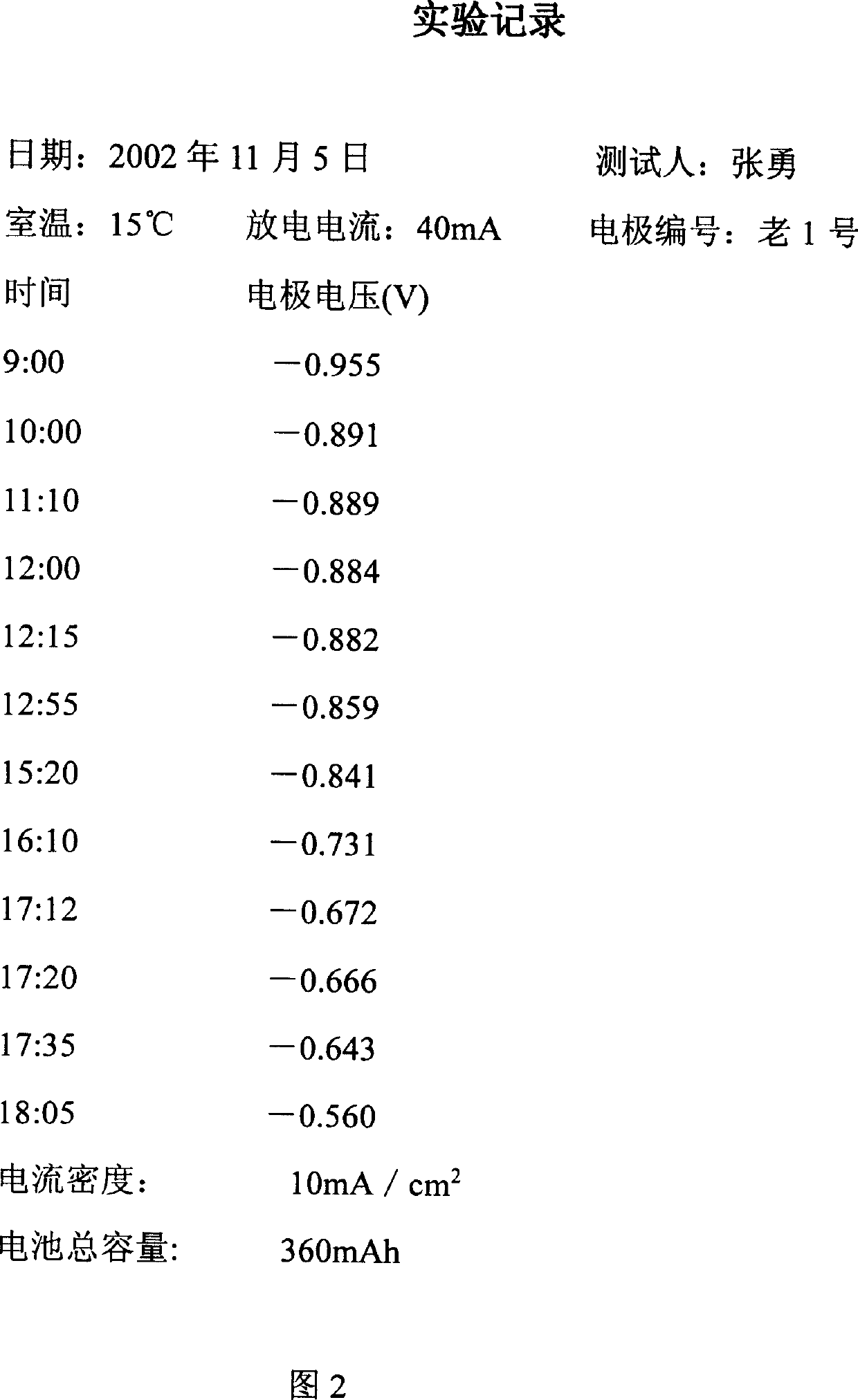

[0019] The embodiment of the iron electrode of the present invention adopts reduced iron powder, ferrite (after sintering), and Al-Sn-Ga alloy powder to be mixed in a ratio of 65:34:1, and sublimed sulfur and graphite powder are added, and NMP (N-picoline ) Dissolve PVDF (polyvinylidene fluoride) as a binder, make an iron electrode by paste method, dry it, and press it into an area of 4cm 2 Iron electrode 1, using vinylon non-woven fabric as battery separator 2, using 6M KOH as electrolyte 3, adding a small amount of organic corrosion inhibitor such as NBL-16 (0.1-0.2g / L) or polyoxyethylene dodecane Esters (0.3-3g / L), etc., can also add a little water glass or inorganic inhibitors such as sodium phosphate; the iron electrode and the nickel electrode 4 in the nickel-metal hydride battery are used to form a battery, and the battery is charged and discharged. test. This embodiment makes battery, at 10mA / cm 2 Discharge under the current density, the specific energy of the iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com