Precious metal carrying hydrogenation catalyst

A technology for hydrogenation catalysts and precious metals, applied in the direction of metal/metal oxide/metal hydroxide catalysts, catalyst carriers, physical/chemical process catalysts, etc., can solve the problems of material pollution, iron loss, etc., and achieve the increase of reaction interface Large, avoid loss, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 189g Na 2 SiO 3 9H 2 O (Zhejiang Wenzhou Dongsheng Chemical Reagent Factory) was dissolved in 800 mL of distilled water, and 3 mol / L HCl solution was slowly added dropwise under stirring condition, the pH value of the solution was adjusted to 13, and it was filtered for later use.

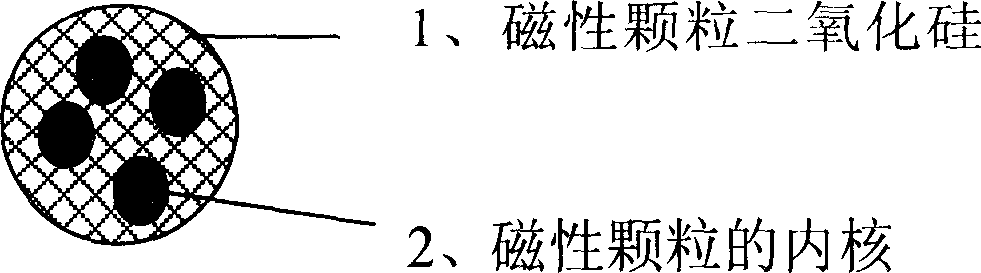

[0048] Add 23.4 g of FeCl to a 2 L stirred reactor filled with 1000 mL of distilled water 3 ·6H 2 O (Beijing Chaoyang Tonghui Chemical Plant) and 8.6g FeCl 2 4H 2 O (Beijing Shuanghuan Chemical Reagent Factory), under the protection of nitrogen, the temperature was raised to 85-90 °C, and 30 mL of 25% NH was added during high-speed stirring. 3 ·H 2 O solution, after stirring at high speed for 3min, use a magnetic separator to separate Fe 3 o 4 Nanoparticle products. Ultrasonic dispersion of the cleaned deposition product in the above pretreated Na 2 SiO 3 solution, and then moved into a 2-liter stirred reactor, heated to 85°C, and under nitrogen protection and stirring conditions,...

Embodiment 2

[0056] 28.4g Na 2 SiO 3 9H 2 O (Zhejiang Wenzhou Dongsheng Chemical Reagent Factory) was dissolved in 600 mL of distilled water, and 3 mol / L HCl solution was slowly added dropwise under agitation to adjust the pH value of the solution to 13, and filtered for later use.

[0057] Add 46.7 g of FeCl to a 2 L stirred reactor filled with 1000 mL of distilled water 3 ·6H 2 O (Beijing Chaoyang Tonghui Chemical Plant) and 17.2g FeCl 2 4H 2 O (Beijing Shuanghuan Chemical Reagent Factory), under the protection of nitrogen, heat up to 85-90 °C, add 160mL of 6Mol / L NaOH solution during high-speed stirring, and after high-speed stirring for 3min, use a magnetic separator to separate Fe 3 o 4 Nanoparticle products. Ultrasonic dispersion of the cleaned deposition product in the above pretreated Na 2 SiO 3 solution, and then moved into a 2-liter stirred reactor, raised the temperature to 85°C, and slowly added HCl solution with a concentration of about 1.5mol / L dropwise to the soluti...

Embodiment 3

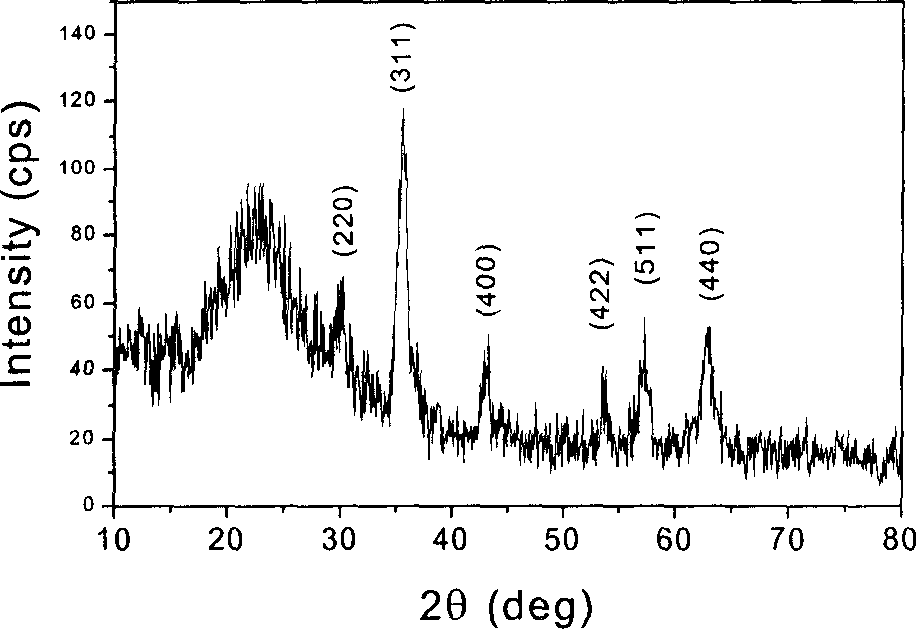

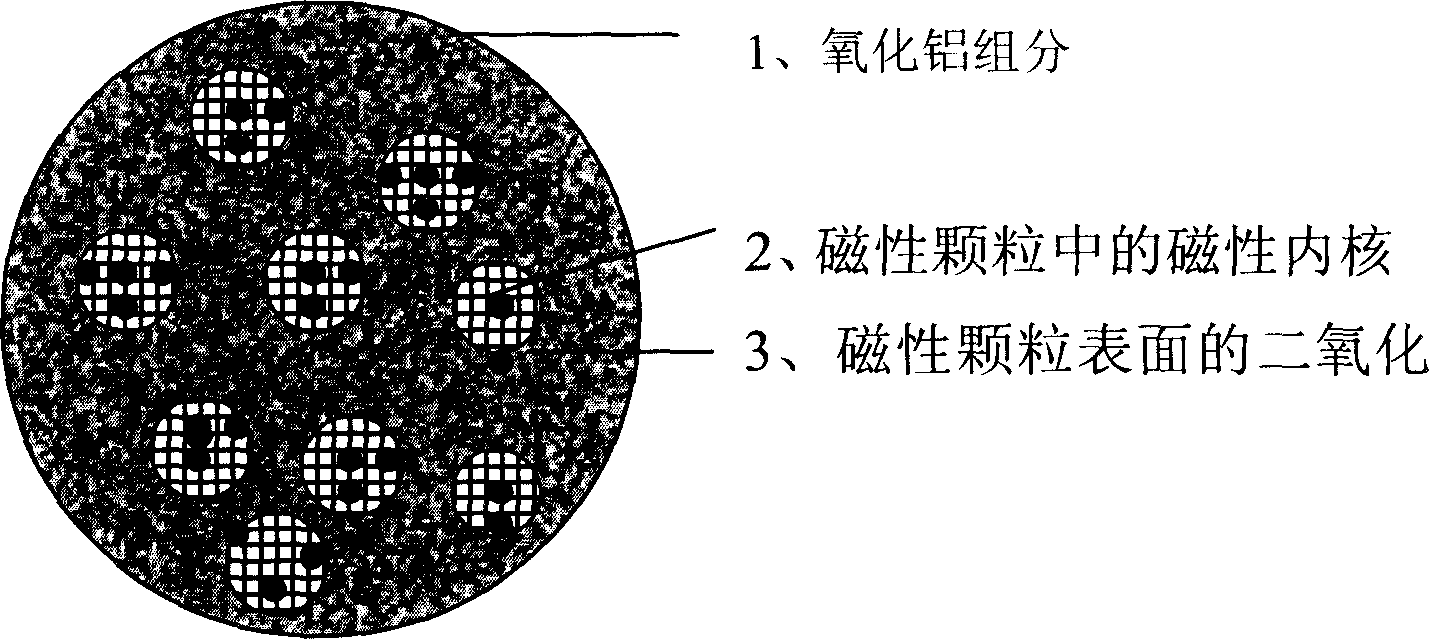

[0063] The above-mentioned AL1 magnetic spherical Al(OH) 3 The product was put into a 1L autoclave containing 0.7L sulfonated kerosene medium, and subjected to hydrothermal treatment at 140°C for 3 hours under the protection of nitrogen. After aging for 6 hours (removing some of the impurities) and drying at 60°C, a magnetic spherical Al(OH) with a boehmite structure (α-AlOOH) can be obtained 3 product, the product is sintered at 580 ° C for 2 hours in an air atmosphere, and about 60 g of γ-Fe-containing 2 o 3 Spherical γ-Al with Magnetic Core 2 o 3 carrier. The content ratio (weight ratio) of each component in the carrier material is: γ-Fe 2 o 3 : SiO 2 :Al 2 o 3 =30:9:61 (in addition, the carrier also contains part of water). This carrier has superparamagnetic characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com