Method and device for epoxidation of propylene using plasma of hydrogen and oxygen

A technology of plasma and epoxidation, which is applied in the direction of organic chemistry, can solve the problems of increased difficulty in preparation, difficulty in industrial use, complex process, etc., and achieve the effect of simple equipment and process and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

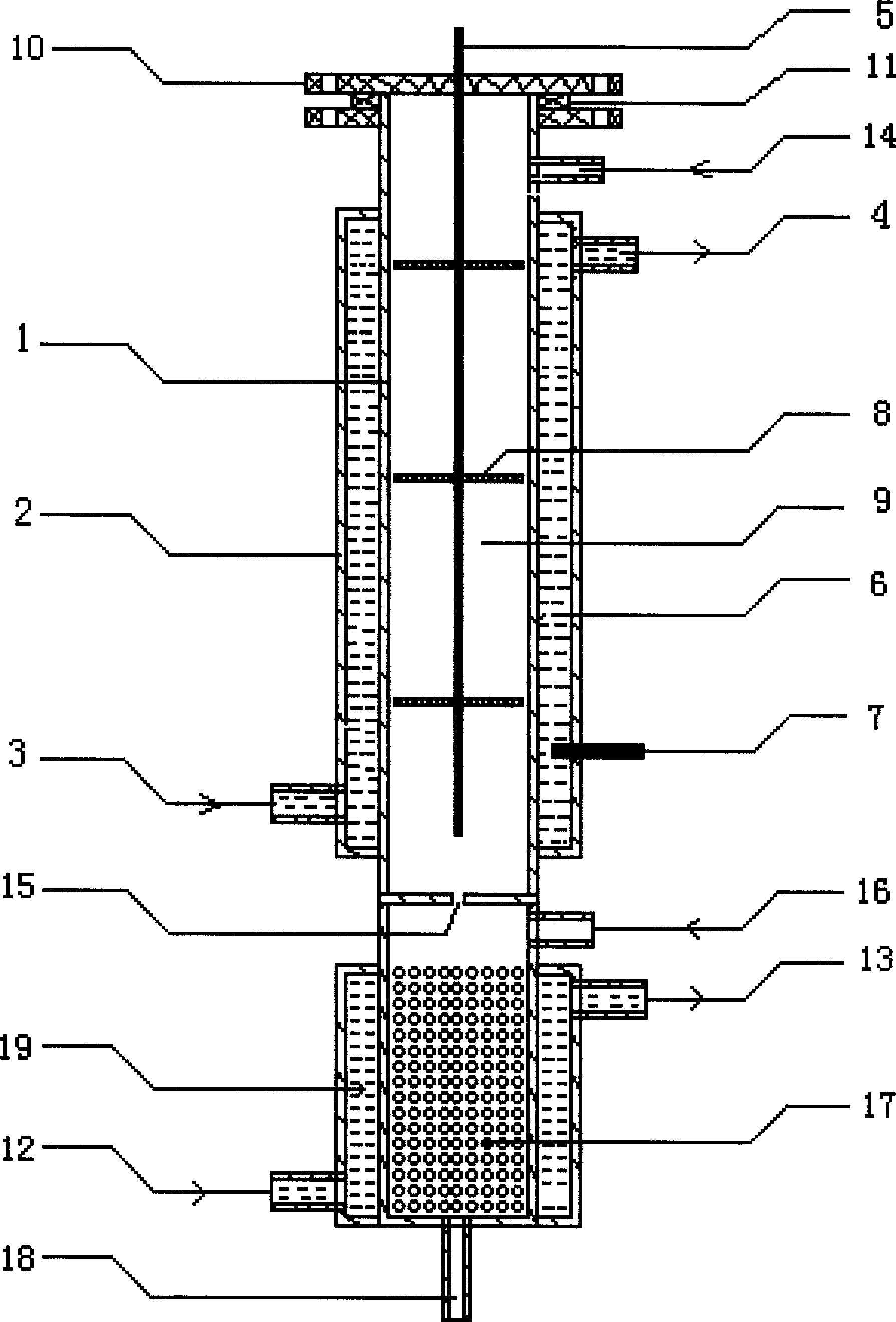

[0027]The device of the invention is made of silicate oxide hard glass. The wall thickness of the inner and outer cylinders of the device is 1.5 millimeters, the inner diameter of the inner cylinder is 9 millimeters, and the annular gap distance between the inner and outer cylinders is 10 millimeters. The length of the discharge area in the upper section of the device is 220 mm, and the length of the annular gap is the same as that of the discharge area. The catalyst bed in the lower section of the device can be filled to a height of 80 mm. The device uses a metal copper wire with a diameter of 0.56 mm and a smooth surface as the discharge electrode, and a metal tungsten wire with a diameter of 1.0 mm and a smooth surface as the current lead-out wire. The catalyst bed is loaded with 4.0 g of spherical titanium silicalite TS-1 catalyst with a diameter of about φ1.5 that has been sprayed and formed. Silica sol with a silicon oxide content of 30% is used as a binder in the cata...

Embodiment 2

[0029] Repeat Example 1, but the temperature of the catalyst bed in the lower section of the device is changed to 60°C, 80°C and 95°C in sequence. After discharging for 10 minutes, according to the analysis results of online gas chromatography, it is calculated that: when the catalyst bed temperature was 60°C, the relative content of propylene oxide to various hydrocarbon compounds reached 1.9% (area normalized), and the selectivity of propylene oxide reached 98%, at this time the temperature of the inner cylinder wall in the upper section of the device is 18.5°C. When the catalyst bed temperature was 80°C, the relative content of propylene oxide to various hydrocarbon compounds reached 2.6% (area normalized), and the selectivity of propylene oxide reached 95%. At this time, the inner cylinder wall temperature of the upper section of the device was 18.5°C. When the catalyst bed temperature was 95°C, the relative content of propylene oxide to various hydrocarbon compounds reach...

Embodiment 3

[0031] Repeat Example 1, but the device of the present invention is made of silicate oxide quartz glass, and the discharge electrode is 18Ni9Ti stainless steel alloy, and the cooling circulating water / ground electrode of the upper section of the device is composed of 2% sodium chloride, and the conductivity is 9.23 mm The water solution of Siemens / cm is responsible, and the discharge voltage of the device is 10KV. Then discharge after 10 minutes, calculate according to the analysis result of online gas chromatography: the relative content of propylene oxide to various hydrocarbon compounds reaches 1.7% (area normalized), and the selectivity of propylene oxide reaches 99%, and at this moment, the upper section of the device The inner cylinder wall temperature is 18°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com