Method for extracting high purity seabuckthorn flavone aglycone

A technology of seabuckthorn flavonoids and an extraction method is applied in the field of high-purity preparation of flavonoid ligands, can solve problems such as no literature disclosure, and achieve the effects of easy industrial production, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

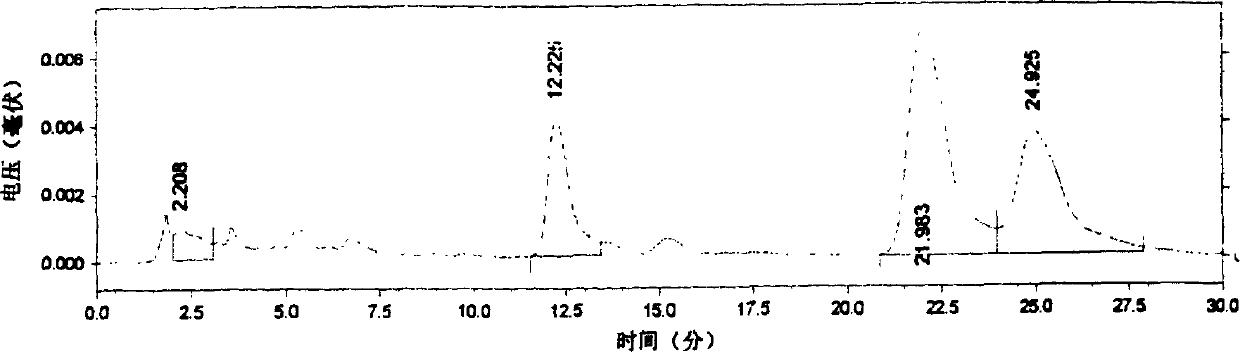

Embodiment 1

[0029] In this example, 40-50 mesh seabuckthorn leaf powder is used as raw material to extract seabuckthorn flavonoids, and the process steps are as follows:

[0030] (1) Leaching

[0031] Weigh 1 kg of seabuckthorn leaf powder of 40 to 50 meshes, extract with 6 kg of methanol for 180 minutes at a temperature of 30°C, extract the extract, and then extract the second, 3 kg, and 3 kg of methanol respectively. For the third and fourth times, the extraction time was 120 minutes, and the extraction temperature was constant.

[0032] (2) Mixing and concentration of extract

[0033] The extracts obtained from the four extractions were mixed, and then subjected to vacuum distillation to recover the extractant. The temperature was controlled at 45°C and the pressure did not exceed -0.08MPa, and the extract was concentrated to 30% of its original volume.

[0034] (3) Extraction

[0035] The extraction is carried out at room temperature (about 20°C), using static extraction, the extra...

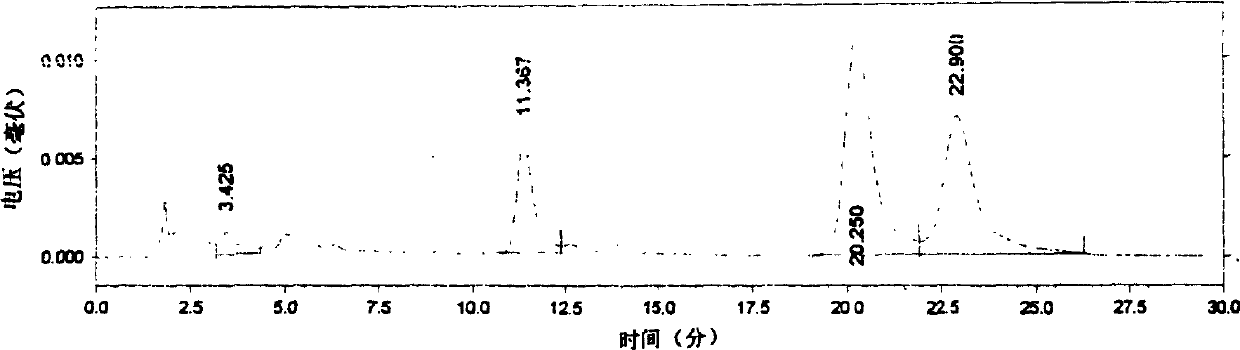

Embodiment 2

[0041] In this example, 50-60 mesh seabuckthorn leaf powder is used as raw material to extract seabuckthorn flavonoids, and the process steps are as follows:

[0042] (1) Leaching

[0043] Weigh 1 kg of seabuckthorn leaf powder of 50-60 meshes, extract with 15 kg of 30% ethanol-water mixture for 40 minutes at a temperature of 90°C, and extract the extract. The second and third extraction times were 30 minutes respectively, the fourth and fifth extraction times were 20 minutes respectively, the second to fifth extraction temperatures were 90°C and the extraction agent was the same as the first extraction time. times the same.

[0044] (2) Mixing and concentration of extract

[0045] The extracts obtained from the five extractions were mixed, and then subjected to vacuum distillation to recover the extractant. The temperature was controlled at 45°C and the pressure did not exceed -0.08MPa, and the extract was concentrated to 30% of its original volume.

[0046] (3) Extraction...

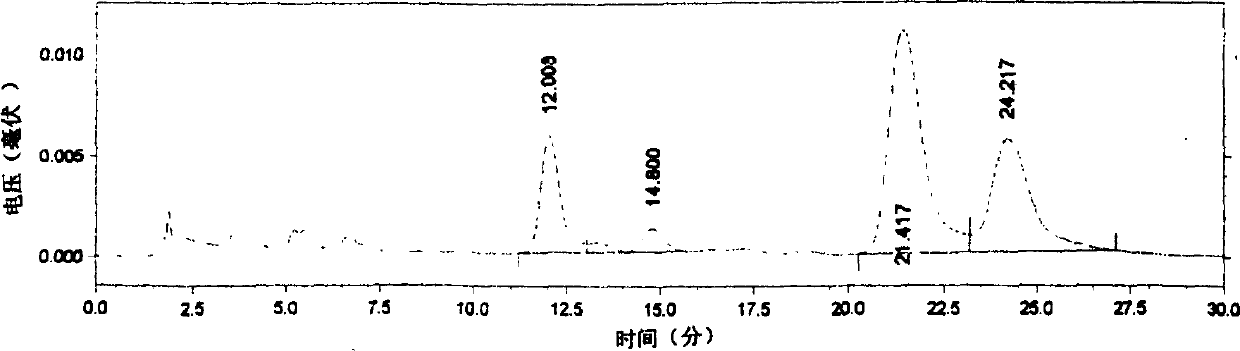

Embodiment 3

[0053] In this example, 40-60 mesh seabuckthorn leaf powder is used as raw material to extract seabuckthorn flavonoids, and the process steps are as follows:

[0054] (1) Leaching

[0055] Weigh 1 kg of 40-60 mesh seabuckthorn leaf powder, extract with 12 kg of 50% methanol-water mixture for 100 minutes at a temperature of 50°C, and extract the extract. For the second to fourth times, 10 kg, 8 kg, and 8 kg of 50% methanol-water mixture were used for extraction for 80 minutes each time, and the extraction temperature was 50° C.

[0056] (2) Mixing and concentration of extract

[0057]The extracts obtained from the four extractions were mixed, and then subjected to vacuum distillation to recover the extractant. The temperature was controlled at 35° C. and the pressure did not exceed -0.08 MPa, and the extract was concentrated to 30% of its original volume.

[0058] (3) Extraction

[0059] The extraction is carried out at room temperature (about 10°C), using dynamic extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com