Method and apparatus for micro-jet enabled, low energy ion generation and transport in plasma processing

A plasma and plasma tube technology, which is used in the field of low-energy ion generation and transportation, and can solve problems such as temperature inconsistency and device damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

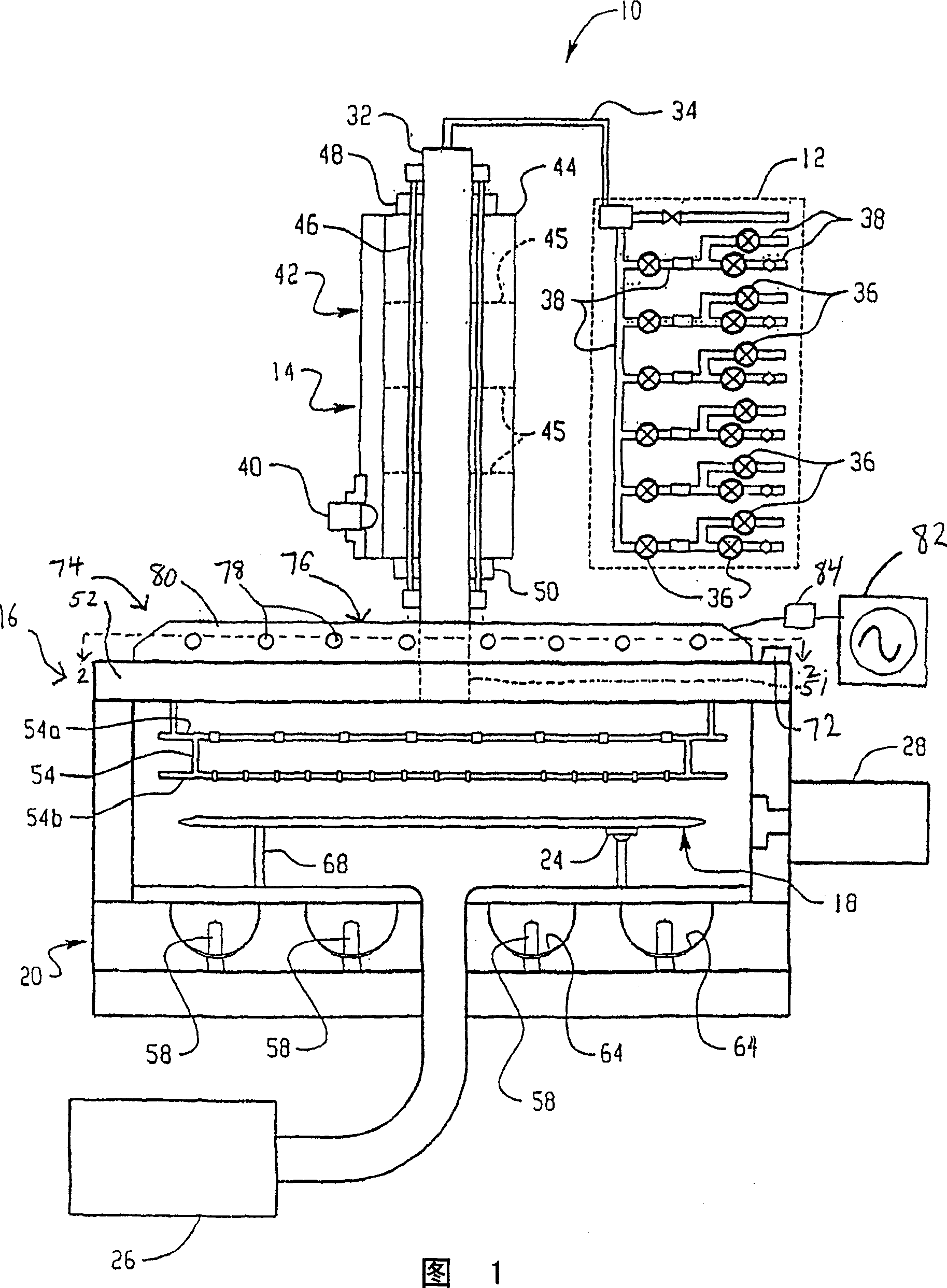

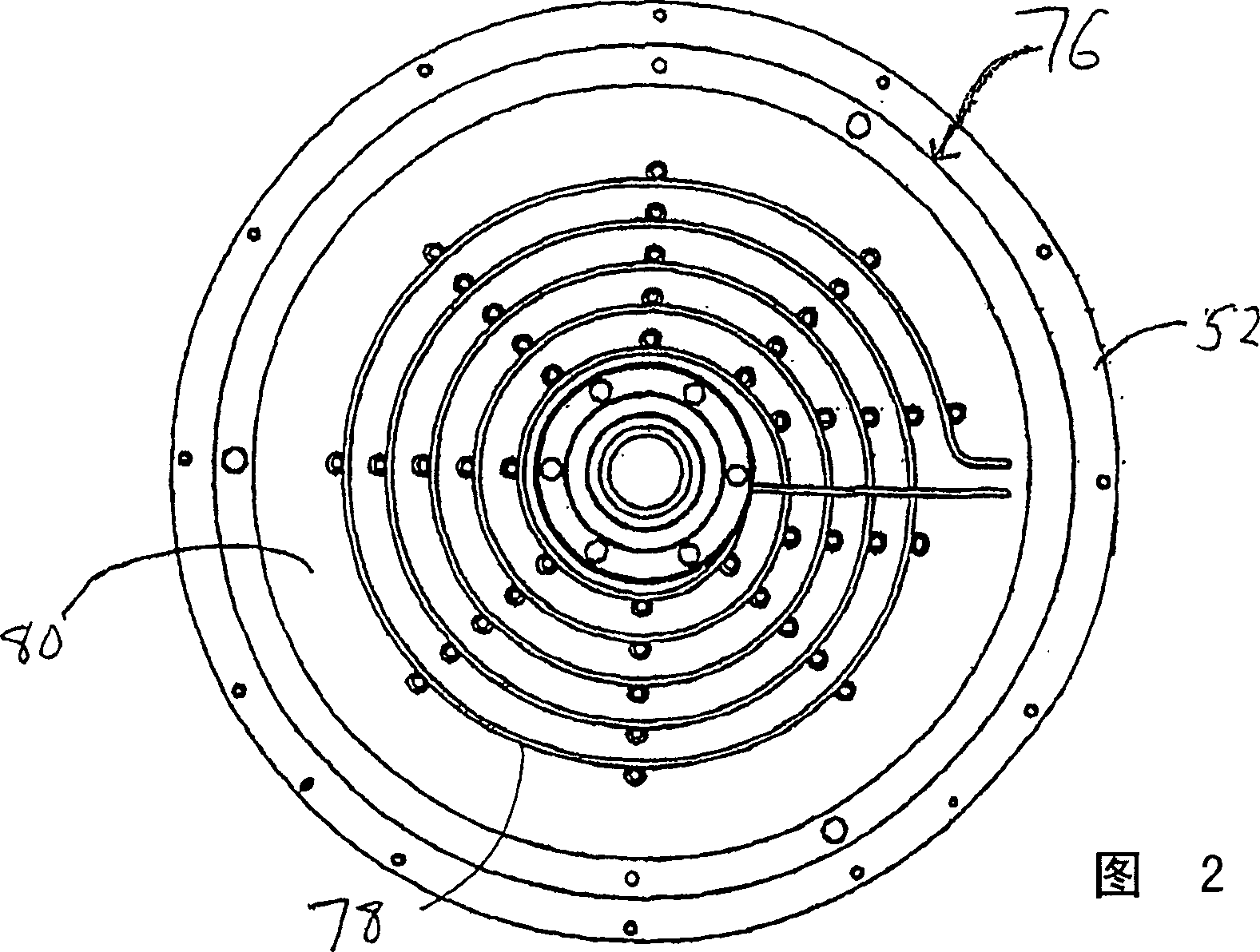

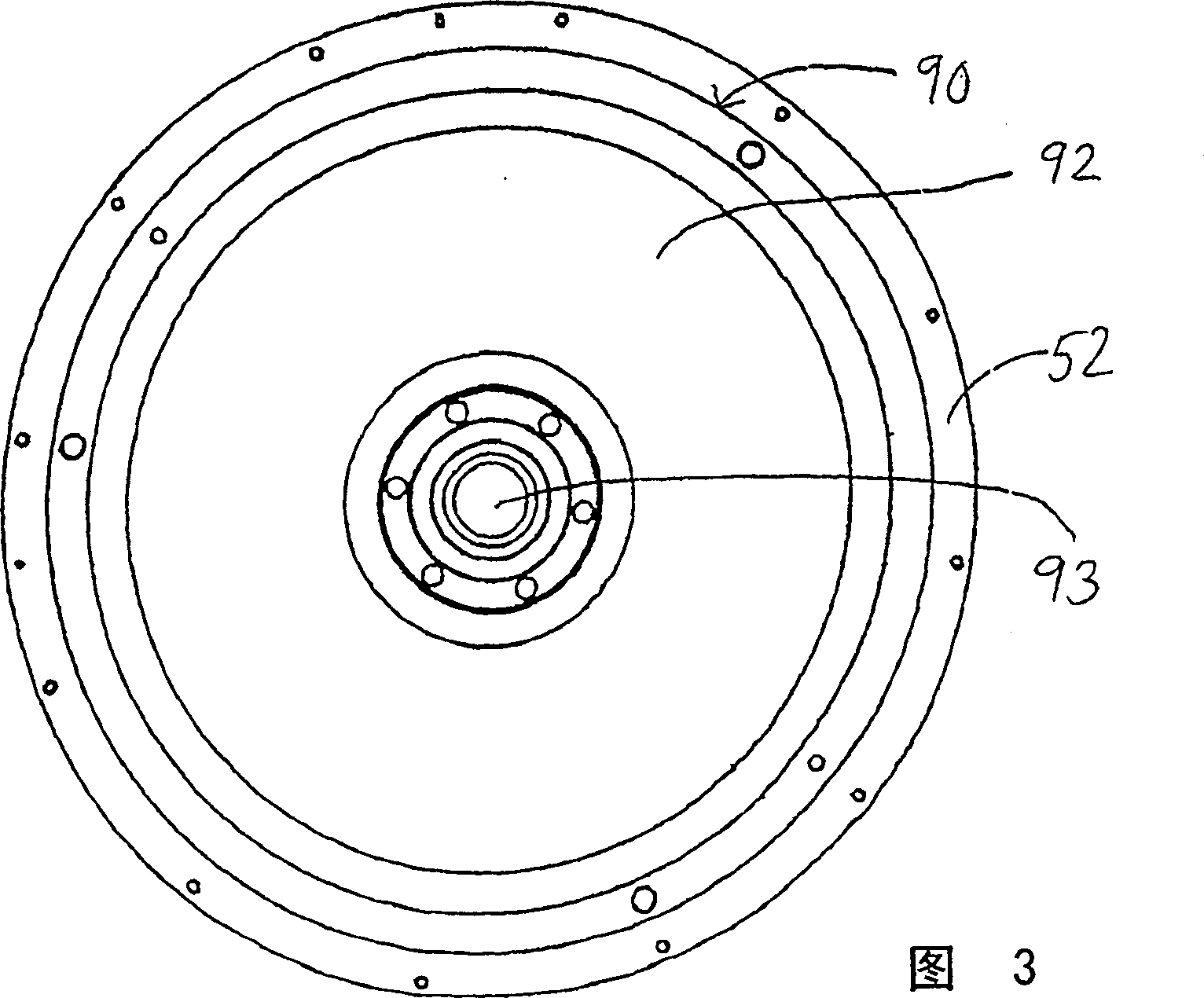

Embodiment Construction

[0022] A novel low-energy ion generation and transport mechanism is presented here; this mechanism protects the wafer from high-energy ions caused by high sheath voltages while enhancing chemical decomposition and subsequent volatilization of the carbonized top layer of ion-implanted photoresist in a uniform manner. Potential harmful effects of ion bombardment. This soft ion-assisted technique has the advantage of achieving an optimal synergy between the ions produced by the auxiliary ion source within the incinerator and the chemicals already present, resulting in greater Faster response.

[0023] We believe that the ions contribute both the physical kinetic energy and the chemical internal energy released by the reaction, effectively lowering the activation energy of the surface reaction. By shielding the wafer from the high sheath potential characteristic of ordinary capacitive discharges, the ions experience a much weaker electric field as they pass through the sheath pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com