Method of bulk processing micro probe based on three dimensional micro processing technology

A technology of micro-processing and batch processing, which is applied in the direction of hypodermic injection devices, etc., can solve the problems of long processing time and less processed materials, and achieve the effect of low processing cost and long mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

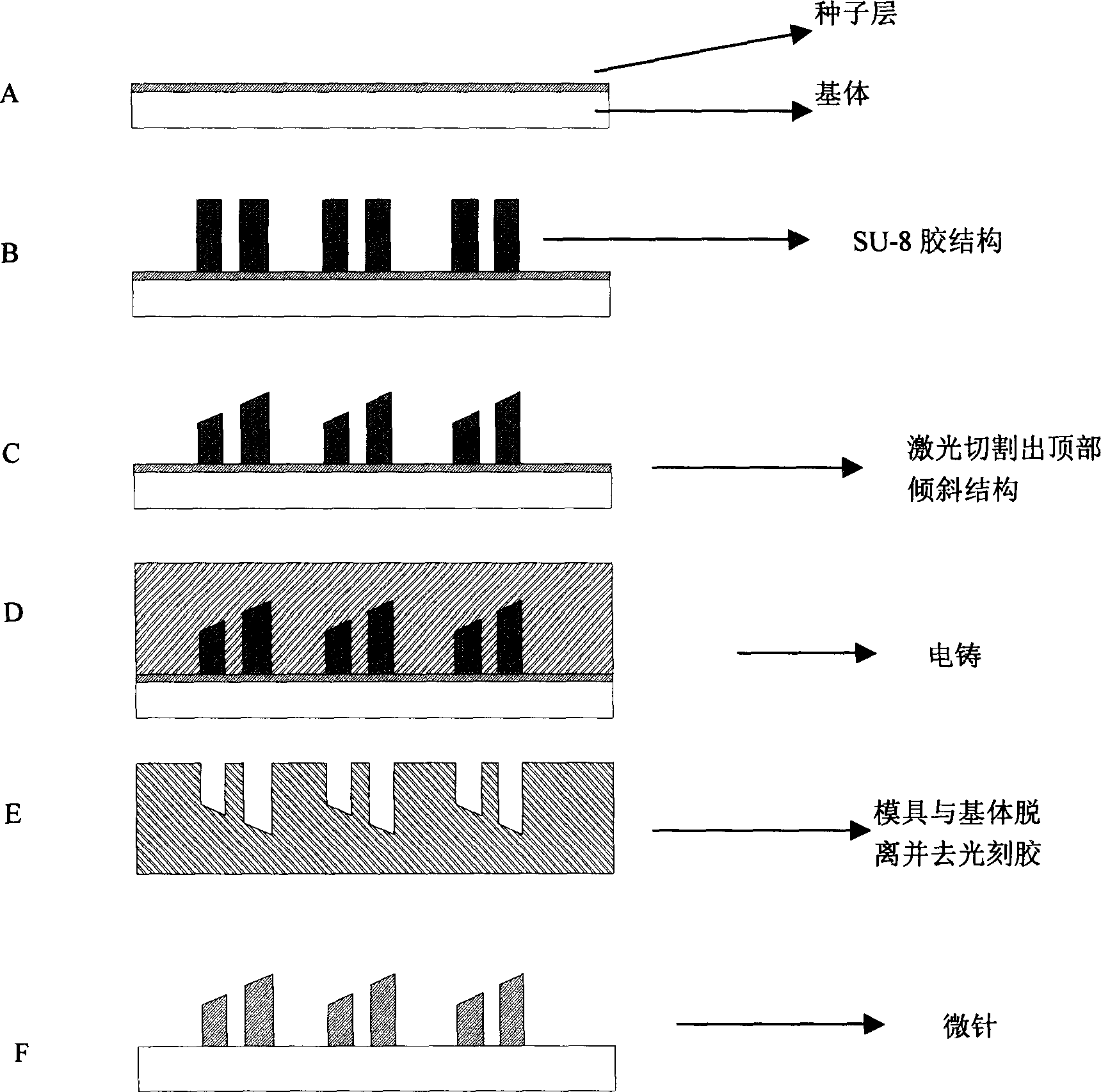

[0023] Such as figure 1 Shown, embodiment is provided below in conjunction with the specific content of the inventive method:

[0024] First deposit 2 microns of titanium metal as a seed layer on the silicon substrate, and then carry out oxidation treatment. The specific oxidation process is: dissolve 15 grams of NaOH in 750ml of DI water. In order to improve the oxidation rate and oxidation uniformity, oxidize at 65 ℃ in a water bath, when the temperature of the water bath reaches 50°C, add 15ml of hydrogen peroxide, when the temperature of the water bath reaches 65°C, put the substrate into it, finish the oxidation in three minutes, then put it into DI water to clean the substrate.

[0025] Spray 500 microns of SU-8 photoresist on the oxidized and cleaned substrate, and then perform pre-baking. The pre-baking conditions are: bake at 65°C for half an hour, bake at 95°C for 2.5 hours, and then cool with the furnace. The pre-baked substrate is exposed, and the exposure conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com