Non moisture absorbable honeybee powder and its making method

A honey powder and difficult technology, which is applied in the field of food processing, can solve the problems such as the hygroscopicity of honey powder products that are not introduced, and achieve the effects of reducing the hygroscopicity, ensuring the storage performance and increasing the variety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

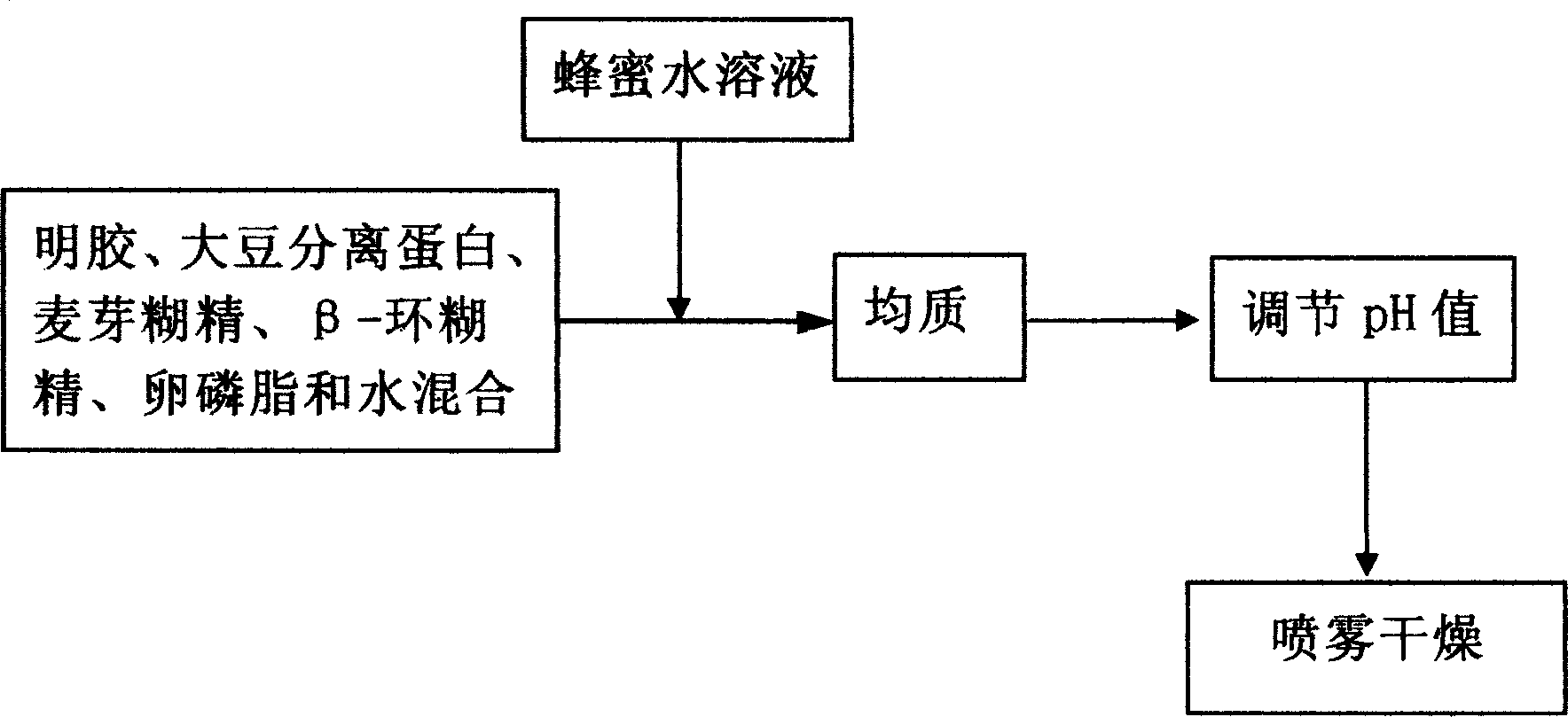

[0010] The invention provides honey powder which is not easy to absorb moisture and a processing method thereof. The honey powder is composed of honey 45-60% by weight; lecithin: 2-3%; soybean protein 1-2%; gelatin 3-5%; β-cyclodextrin 2.5-3.5% and the balance is malt paste Refined, the pH value is adjusted to 7 with an acidity regulator, and the moisture in the solution is removed by spray drying technology to obtain a honey powder that is not easy to absorb moisture. Its production process is:

[0011] 1). Completely dissolve the gelatin, soybean protein and lecithin in the above weight percentages in water, heat to 55°C, and stir evenly; then dissolve maltodextrin and β-cyclodextrin in water, add honey, and stir evenly Mix and adjust the solids content to 30%.

[0012] 2). Grind three times with a colloid mill, 15S each time, then add an equal mixture of acidity regulator disodium hydrogen phosphate and sodium bicarbonate to the mixture, adjust the pH value to 7, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com