Method for making composite substrate of microstrip gas-compartment detector

The technology of a composite substrate and manufacturing method, which is applied in the field of manufacturing composite substrates of microstrip gas chamber detectors, can solve problems such as difficult to obtain S8900 glass, reduce multi-level scattering, etc., achieve excellent physical and chemical stability, improve stability, Effect of High Gas Gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

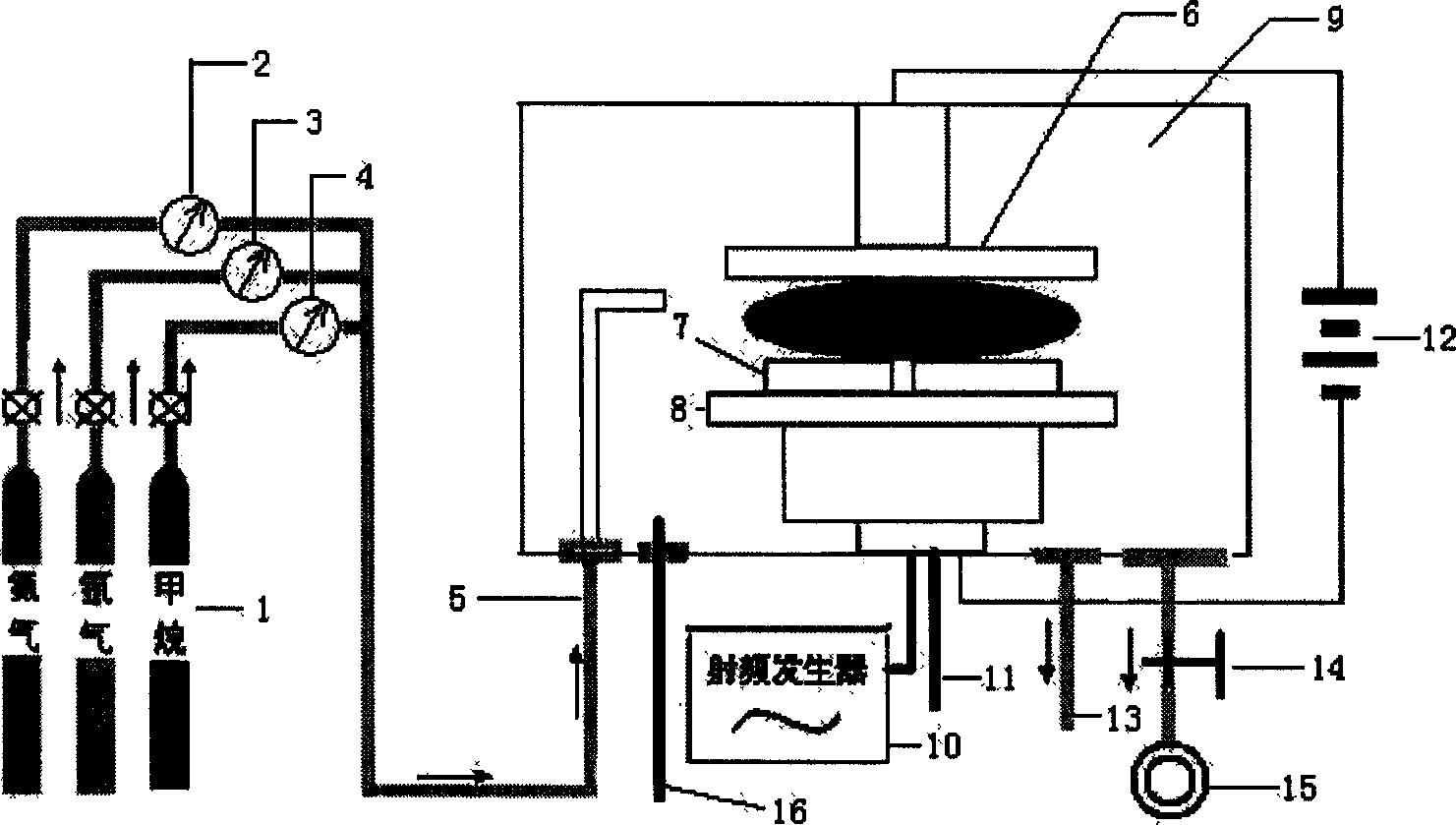

[0024] Use optical glass D263 with a thickness of 0.5mm and an area of 2cm×2cm as the substrate, and ultrasonically clean it in acetone and deionized water for 10 minutes in sequence. After drying, the substrate was placed into a radio frequency plasma-assisted chemical vapor deposition device (such as figure 1 ) on the cathode graphite target 7 in the vacuum reaction chamber 9, the radio frequency frequency is 13.56 MHz, and high-purity (99.99%) methane gas and high-purity (99.998%) argon gas are used as reactants. The flow of the two gases is controlled by their respective flow meters and mixed before entering the reaction chamber. The flow rate of the argon branch is controlled at 60ml / min, and the flow rate of methane is 30ml / min. A vacuum pump+molecular pump air extraction system 15 and a pressure reducing valve 14 are connected below the reaction chamber 9, which can carry out high vacuum and decompression, and maintain the stability of the air pressure in the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com