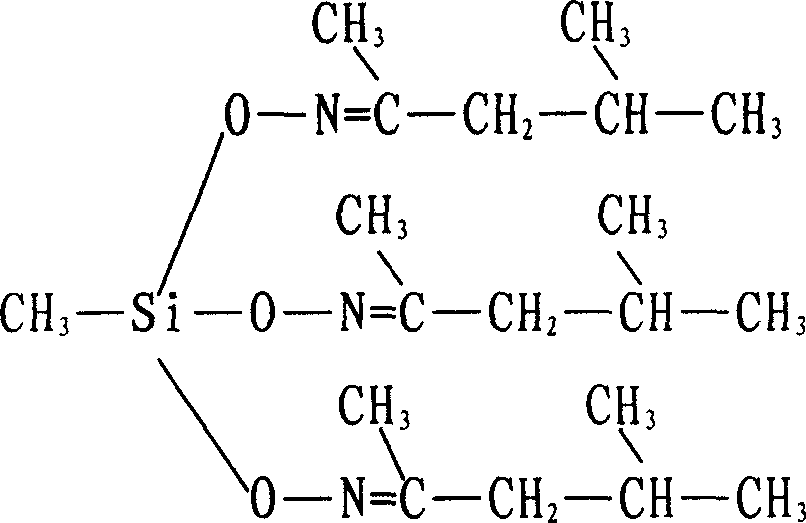

Process for preparing methyl tri (methyl isobutyl ketoximino) silanes

A technology of methyl isobutyl ketone oxime and monomethyltrichlorosilane, which is applied in the direction of silicon organic compounds, can solve the problems of slow vulcanization speed, fast surface vulcanization, and metal corrosion, and achieve improved stability and transparency, The effect of increasing the relative content and improving the cohesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: In a 1 liter dry four-neck flask with a thermometer condenser, stirring, and a constant pressure barrel funnel, add 180 grams of methyl isobutyl ketoxime, 283 grams of petroleum ether and 175 grams of urea, and stir to dissolve for 5 minutes Finally, under continuous stirring and at 20°C, start to add 80 grams of methyltrichlorosilane dropwise. When the dropwise addition is completed in 1 hour, the temperature is 40°C, and then the temperature is raised to 50-55°C, and within this temperature range The stirring reaction was continued for 3 hours. Stand in a separatory funnel to separate into two phases. The lower phase was separated and neutralized with 270 grams of ammonia water. Move the supernatant liquid to another dry three-necked flask, and pass through ammonia to neutralize to PH=7.5 under stirring to precipitate ammonium chloride, separate the ammonium chloride after filtration, and transfer the filtrate to a distillation flask, Pressure distilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com