Preparation method of low oxygen content microballon parent metal powder and its special equipment

A low oxygen content, solder powder technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problems of wide powder particle size distribution, poor powder sphericity, low yield, etc., to achieve powder particle size Narrow distribution, good sphericity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of Pb-Sn alloy medium particle size powder (74~104μm) in air:

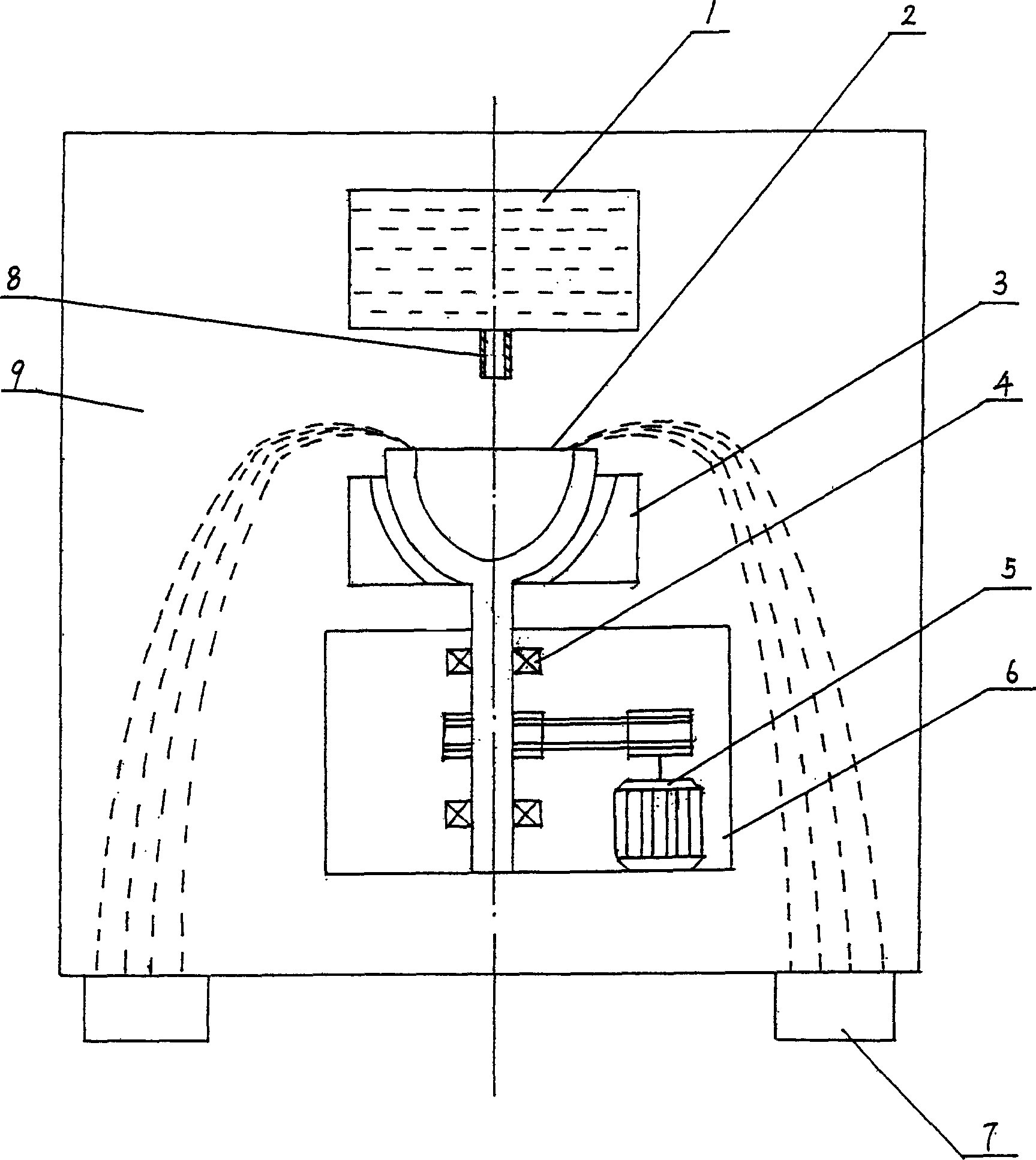

[0024] Such as figure 1 As shown, the special equipment of this embodiment includes a melting bag (crucible) 1 placed in a closed atomizing container 9, an atomizer 2, a thermostat 3, a bearing 4 and a motor 5 that drives the atomizer to rotate, wherein The atomizer 2 is located below the melting bag 1 and is a rotary container with an open upper end. The thermostat 3 is installed on the bottom of the atomizer 2, and the bearing is installed on the rotating shaft of the atomizer. The outer side of the rotating shaft is covered with a water cooling chamber 6 and a motor 5 Placed in the water cooling chamber 6, the bottom of the atomizing container 9 is connected with the powder collecting chamber 7; the diameter of the atomizer is 50mm, and the motor 5 is a high-speed motor driven by a belt.

[0025] Take 2 kg of Pb-61.9% Sn alloy, heat it to 250°C in a crucible with leak 8 to melt it, preheat ...

Embodiment 2

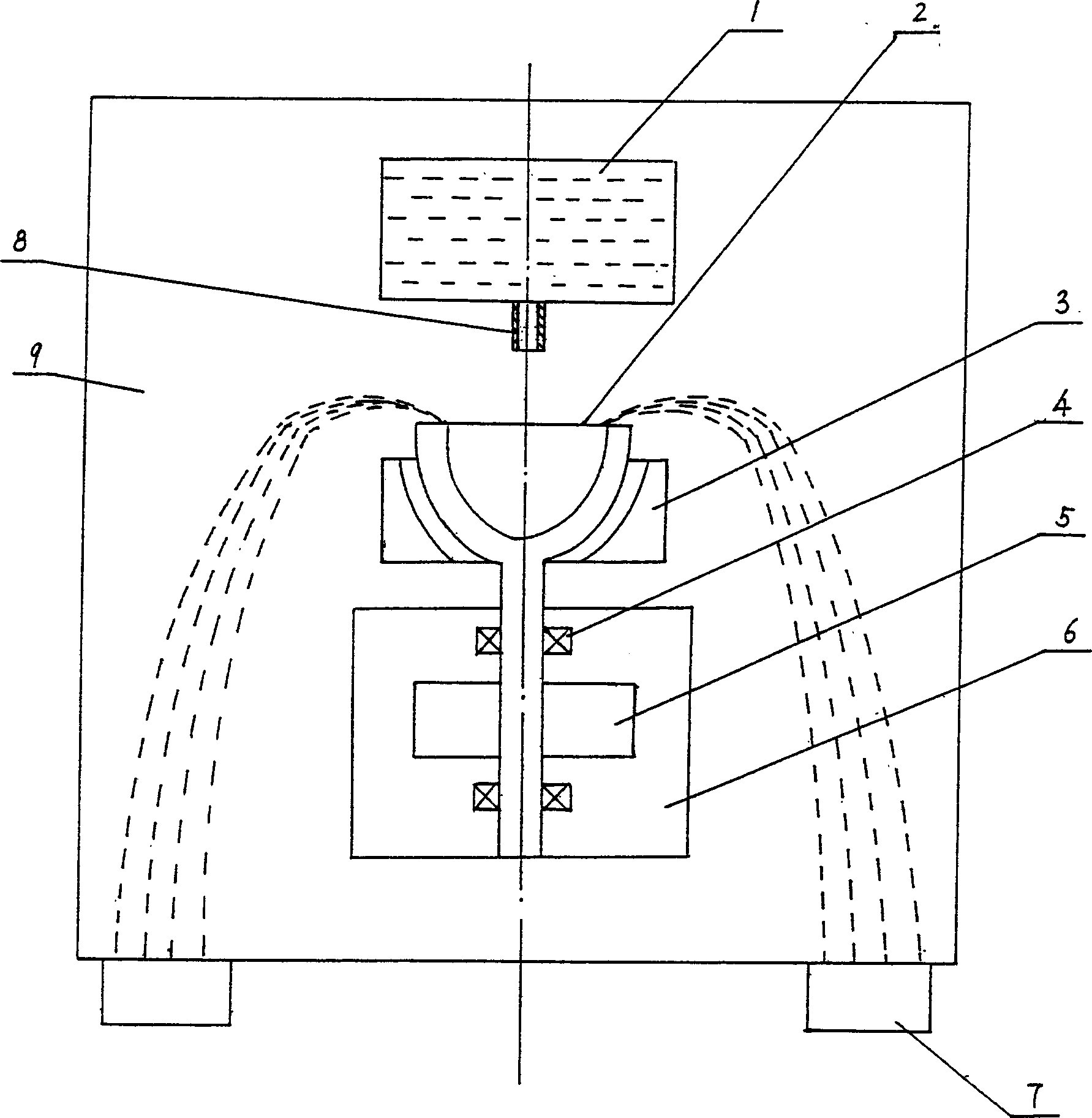

[0027] Prepare Pb-Sn alloy fine-grained powder (44~74 μ m) in airtight container, and the difference with embodiment 1 is: as figure 2 As shown, the diameter of the atomizer is 60mm, and the motor 5 is a high-speed motor coaxial with the atomizer.

[0028] In the airtight container, fill 0.1MPa high-purity nitrogen gas, the oxygen content of the gas is less than 100ppm, heat 20 kg of Pb-61.9% Sn alloy to 300 ℃ to melt, and use a coaxial high-speed motor to atomize the 60mm diameter The machine is accelerated to 10,000 rpm, and the flow rate of the melt is controlled to be 15-25 g / s after the stopper is opened. The particle size range of the obtained spherical powder is 44-74 μm, and the oxygen content of the powder is 80 ppm.

Embodiment 3

[0030] Prepare Pb-Sn alloy very fine-grained powder (30~50 μm) in airtight container, and difference with embodiment 2 is: in airtight container, be filled with 0.09MPa high-purity argon gas, the oxygen content of its gas is less than 100ppm , heat 20 kg of Pb-61.9% Sn alloy to 320 ° C to melt, use a coaxial high-speed motor to accelerate the atomizer with a diameter of 60 mm to 12000 rpm, and control the flow rate of the melt to 10 to 15 after opening the stopper g / s, the particle size range of the obtained spherical powder is 30-50 μm, and the oxygen content of the powder is 85 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com