Mineralized fibrion/macromolecule composite porous material and preparation method

A technology of polymer materials and porous materials, applied in the field of mineralized silk protein/polymer composite porous materials and their preparation, can solve the problems of safety, high cost, complicated purification process, etc., and achieve low cost and good biological phase. Capacitive, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

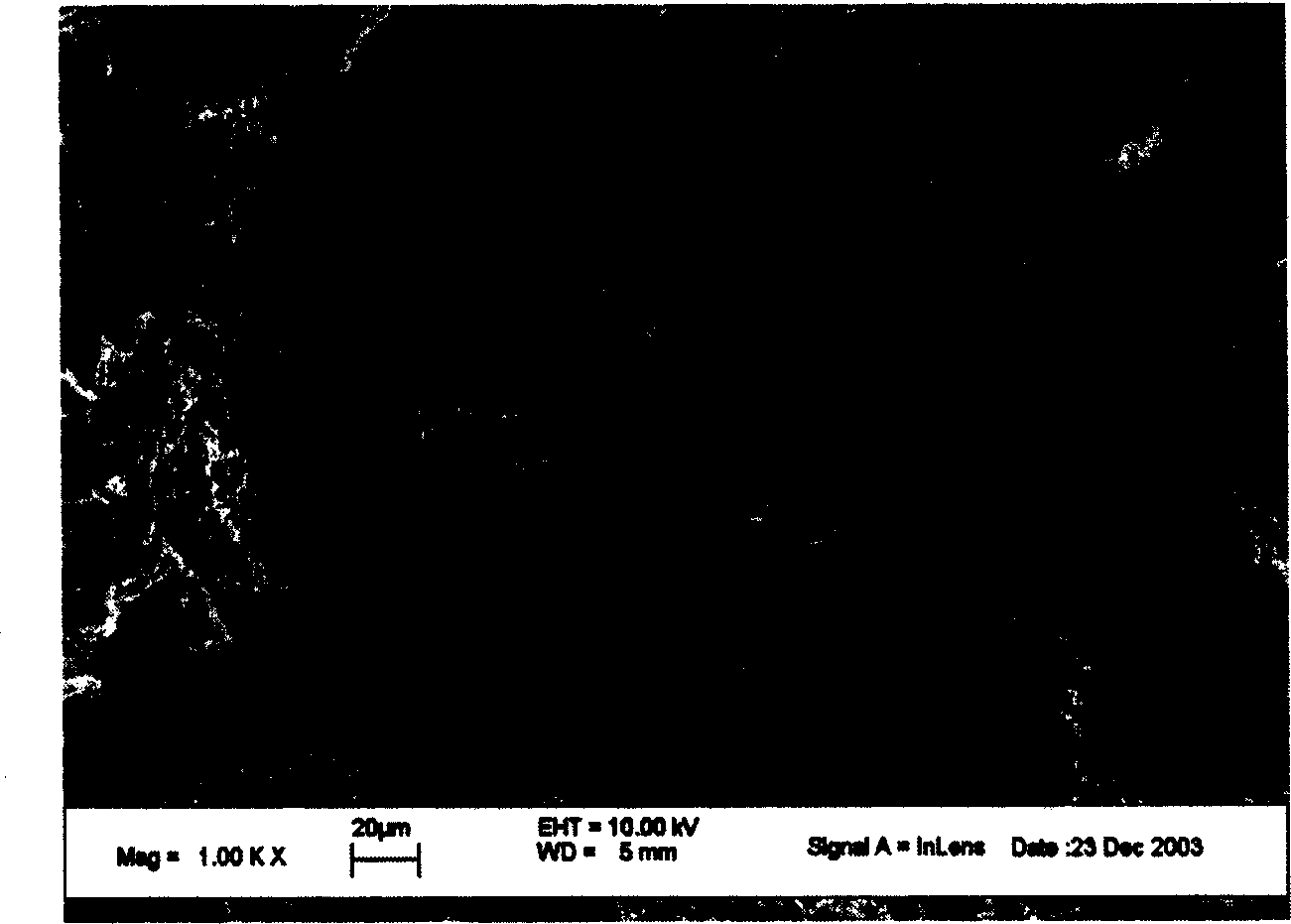

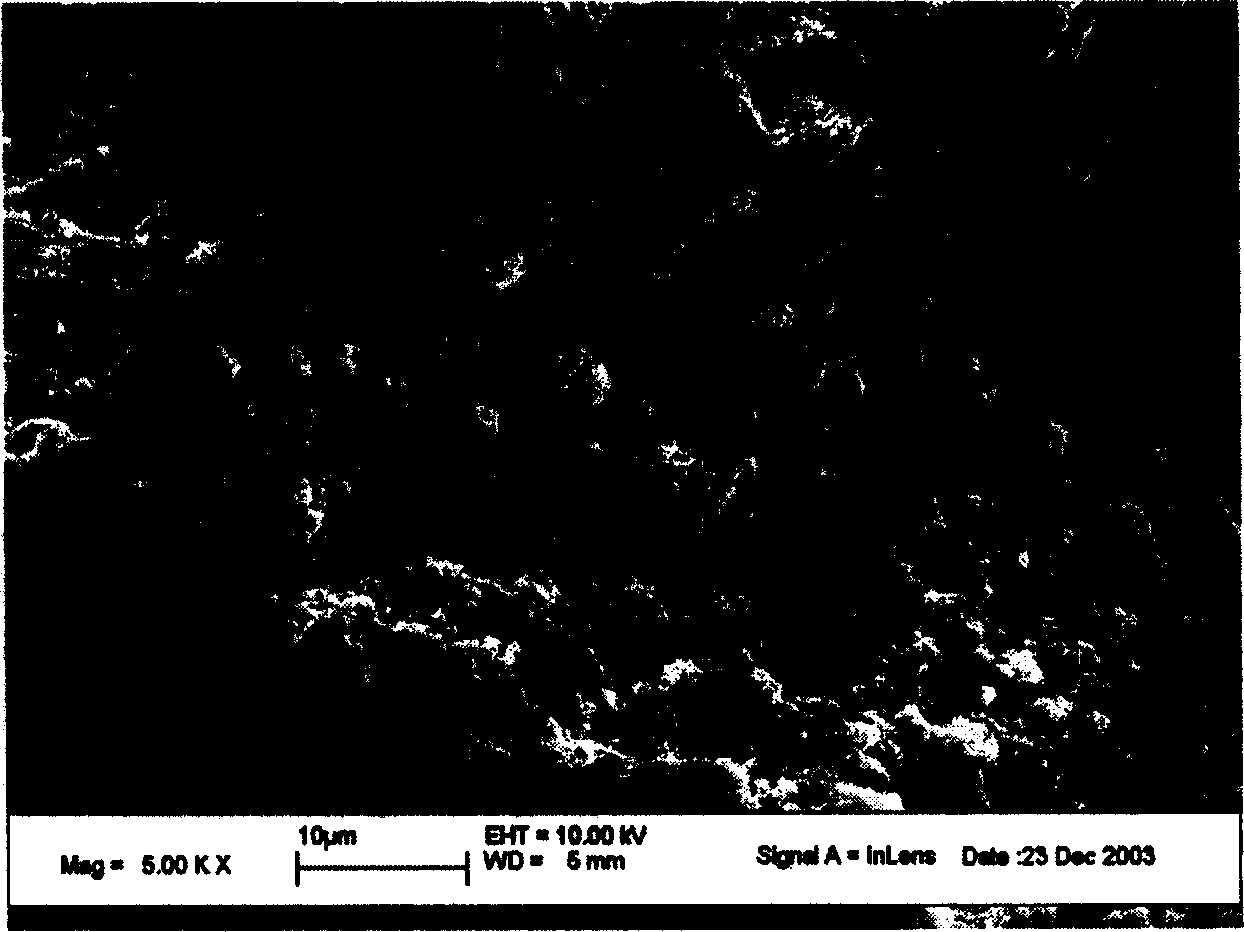

Image

Examples

preparation example Construction

[0026] The preparation method of the framework material proposed in the present invention is mainly based on the mineralized silk protein material, and further compounding polymer materials to prepare the framework material for bone repair.

[0027] It mainly includes the following steps:

[0028] (1) Add a solution containing calcium ions dropwise in the silk protein solution, so that the mass percentage concentration of silk protein in the solution is finally 0.3%-30%, and the molar concentration of calcium ions is finally 0.01-2mol / L. Continuous stirring is required; continue to add phosphate ions dropwise to the solution in a molar ratio of Ca:P=1 to 2:1 under stirring, and finally adjust the pH value to 7.4 to 13;

[0029] (2) Stir the above solution and let it stand. After the precipitation and the supernatant are layered, remove the supernatant, centrifuge to separate the precipitation, wash repeatedly with deionized water until neutral, put the precipitation into a lyo...

Embodiment 1

[0037] 1) In the 500ml silk protein solution with a concentration of 0.9%, add dropwise 500ml of Ca(OH) with a concentration of 0.25mol / 2 After solution, continue to slowly add NaH with a concentration of 0.25mol / L 2 PO 4 The solution is 300ml, and the pH needs to be adjusted to 13 by constant stirring during the dropwise addition.

[0038] 2) Stir the above system, let it stand, remove the supernatant, centrifuge to separate the precipitate, wash it repeatedly with deionized water to remove the salt and reach neutrality, put it into a lyophilizer to freeze dry, and then grind the dried product A dry powder was prepared.

[0039] 3) Weigh 1.0g PLA into a flask, add 10ml 1,4-dioxane to obtain a 10% solution, stir the mixture at room temperature for 2 hours, add 1.0g of the prepared mineralized silk protein, and mix well.

[0040] 4) Pour the mixed solution into a mold, freeze and freeze in a freeze dryer.

[0041]5) Demoulding the above-mentioned molding materials, washing...

Embodiment 2

[0043] 1) In the 900ml silk protein solution with a adjusted concentration of 33%, add 50ml of CaCl with a concentration of 0.2mol / L 2 After the solution, continue to slowly drop Na with a concentration of 0.2mol / L 2 HPO 4 Solution 50ml, mix well with a stirrer while adding dropwise. Slowly add NaOH solution dropwise to the solution in the first step above while stirring until the pH value is stable at 7.4.

[0044] 2) Stir the above system, let it stand, remove the supernatant, centrifuge to separate the precipitate, wash it repeatedly with deionized water to remove the salt and reach neutrality, put it into a lyophilizer to freeze dry, and then grind the dried product A dry powder was prepared.

[0045] 3) Weighing 1.5g of sodium alginate, adding 1.0g of the prepared mineralized silk protein, and then mixing evenly.

[0046] 4) Pour the mixed solution into the mold, put the mold into 5% calcium chloride solution and cross-link for 12 hours, then remove the film, soak in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com