Amide aramid fiber paper, preparation method and application

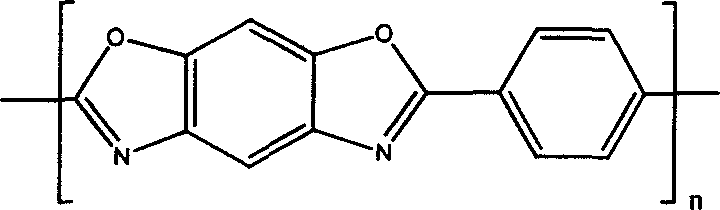

A kind of aramid amide paper, aramid fiber technology, applied in papermaking, textile and papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc. It is difficult to obtain the uniformity of paper and other problems, and achieve the effects of good chemical stability and adaptability, insensitivity to humid environment, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Aramid paper was prepared by wet forming by mixing 20% (weight percent) of aramid short fibers with 80% (weight percent) aramid pulp. The aramid staple fibers are meta-aramid amide fibers (domestic aramid 1313), and the staple fibers are 3.33 dtex and 9 mm in length. The aramid fiber pulp is the meta-aramid fiber amide pulp prepared by the precipitation method.

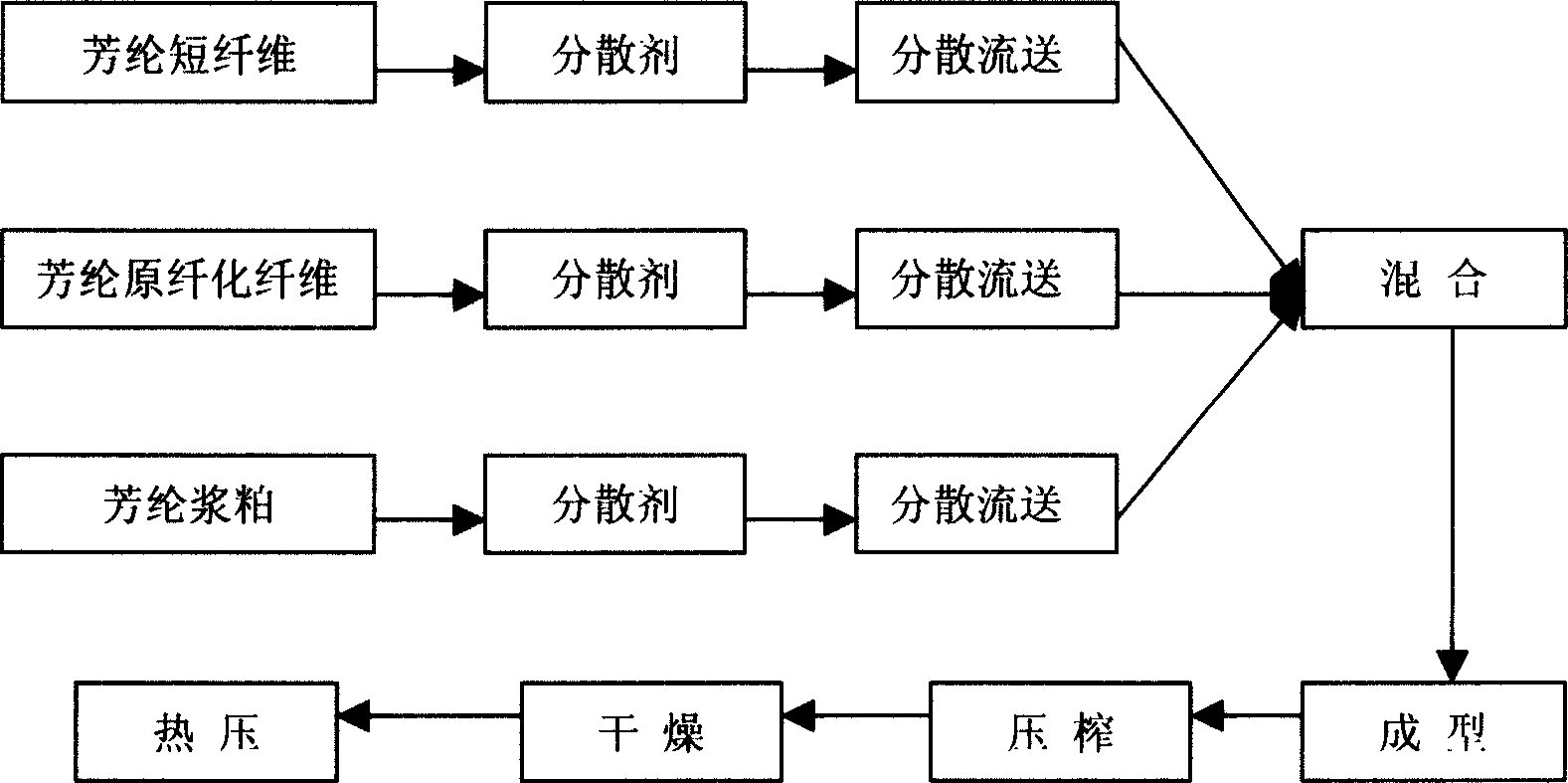

[0026] like figure 1 As shown in the process flow, the above-mentioned aramid staple fibers are dispersed in an aqueous solution with a beater, and 0.15% of octadecylamine (concentration in the aqueous solution) and 0.01% of cationic polyacrylamide (PAM) (in the aqueous solution) are added to the aqueous solution. concentration in aqueous solution) as a dispersing aid to obtain a uniformly dispersed suspension. The above-mentioned aramid fiber pulp was dispersed in an aqueous solution with a beating machine, and sodium carboxymethyl cellulose (CMC) 0.01% (concentration in the aqueous solution) was added to ...

Embodiment 2

[0030]Aramid paper was prepared by mixing 60% aramid short fibers (weight percent), 35% aramid fibrillated fibers (weight percent) and 5% aramid pulp by wet forming. The aramid short fibers are meta-aramid amide fibers (domestic aramid fibers 1313), and the short fibers are 3.33 dtex and 6 mm in length. The aramid fibrillated fibers are para-aramid amide fibers that have undergone fibrillation treatment. The aramid fiber pulp is the meta-aramid fiber amide pulp prepared by the precipitation method.

[0031] like figure 1 As shown in the technological process, the above-mentioned aramid fiber is dispersed in an aqueous solution with a beating machine, and sodium dodecylbenzenesulfonate 0.002% (concentration in the aqueous solution) is added to the aqueous solution as a dispersing aid to obtain a uniform dispersion. suspension. Disperse the above-mentioned fibrillated fibers in an aqueous solution with a beater, and add 0.002% sodium dodecylbenzenesulfonate (concentration in ...

Embodiment 3

[0035] Aramid paper is prepared by mixing 40% aramid short fibers (weight percentage), 20% aramid fibrillated fibers (weight percentage) and 40% aramid pulp by wet forming. The aramid short fibers are para-aramid amide fibers (domestic aramid fibers 1313), and the short fibers are 3.33 dtex and 6 mm in length. The aramid fibrillated fibers are para-aramid amide fibers that have undergone fibrillation treatment. The aramid fiber pulp is the meta-aramid fiber amide pulp prepared by the precipitation method.

[0036] like figure 1 As shown in the process flow, the above-mentioned aramid staple fibers are dispersed in an aqueous solution with a beater, and 0.15% of octadecylamine (concentration in the aqueous solution) and 0.01% of cationic polyacrylamide (PAM) (in the aqueous solution) are added to the aqueous solution. concentration in aqueous solution) as a dispersing aid to obtain a uniformly dispersed suspension. Disperse the above fibrillated fibers in an aqueous solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com