Detonation method for synthesizing oxide powder

A technique of oxide powder, synthesis method, applied in the field of physics or chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

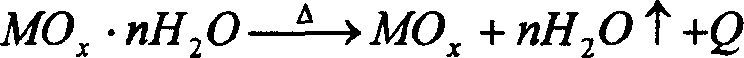

Image

Examples

Embodiment 1

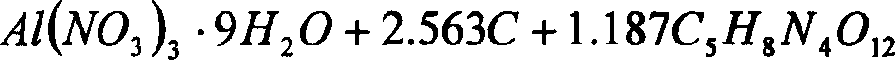

[0054] Mix 1 kg each of aluminum nitrate nonahydrate and Taian explosive powder, add 82 grams of charcoal powder, detonate according to the following chemical equation, and reach the oxygen balance:

[0055]

[0056]

[0057] Put the above-mentioned explosive into a spherical container with a diameter of 3 meters and detonate it with a No. 8 detonator to obtain 135g of nano-alumina, which is a spherical powder with a diameter of less than 50nm.

Embodiment 2

[0059] Mix 1 kg of magnesium nitrate hexahydrate and 1 kg of Taian explosive powder, add 9 grams of charcoal powder, detonate according to the following chemical equation, and reach the oxygen balance:

[0060]

[0061]

[0062] Put the above-mentioned explosive into a spherical container with a diameter of 3 meters and detonate it with a No. 8 detonator to obtain 157g of nano-magnesium oxide, which is a spherical powder with a diameter of less than 50nm.

Embodiment 3

[0064] Mix 2kg of ammonium nitrate powder with 600g of titanium powder, and detonate according to the following chemical equation to achieve oxygen balance:

[0065]

[0066] Put the above-mentioned explosive into a spherical container with a diameter of 3 meters and detonate it with 50g of Taian to obtain 1kg of nano-titanium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com