Organic light-emitting device employing doped hole transporting layer and/or hole injecting layer

A technology for organic light-emitting devices and hole injection layers, which can be used in semiconductor/solid-state device manufacturing, household components, light-emitting materials, etc., and can solve problems such as impact and unfavorable luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

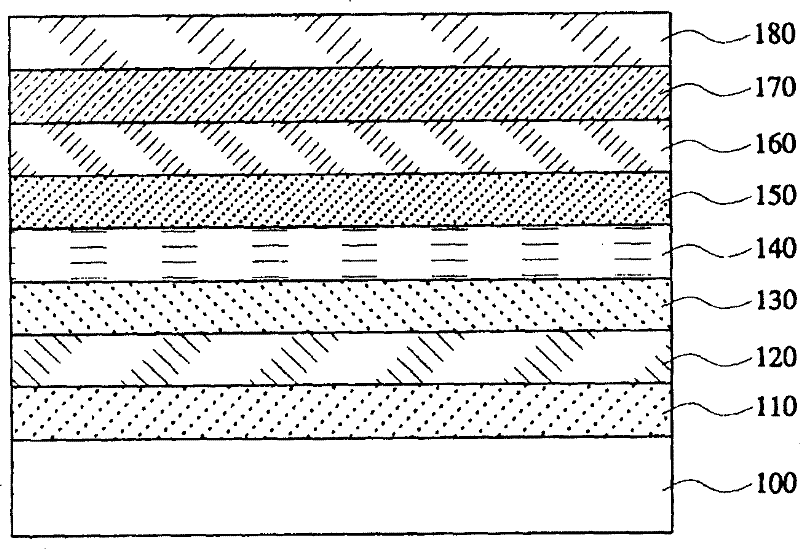

[0045] The anode is formed on the substrate using ITO (Indium Tin Oxide). On the substrate on which ITO has been formed: cleaning; 15 minutes UV-O 3 Treatment; coating with a mixed solution of BFE (obtained from Dow Chemical Company) and 5 wt % of 9,10-dicyanoanthracene (hereinafter referred to as "DCA") at an appropriate rotation speed and a thickness of 30 nm; and heat treatment. Thus, a hole injection layer was formed. The electron affinity of BFE is 2.46eV and that of DCA is 3.2eV.

[0046] On the substrate on which the hole injection layer has been formed, a hole transport layer, an emission layer, a hole blocking layer, an electron transport layer, an electron injection layer, and a cathode are sequentially formed, and sealed with a hygroscopic agent and a glass cover the substrate.

[0047] 30 nm of IDE320 (from IDEMITSU COMPANY) was used as the hole transport layer, and 20 nm of IDE140 (from IDEMITSU COMPANY) containing 6 wt% of IDE105 was used as the emission laye...

Embodiment 2

[0049] An organic light-emitting device was prepared in the same manner as in Example 1, except that a hole transport layer was not formed.

Embodiment 3

[0061] Prepare an organic light-emitting device in the same manner as in Example 1, except that the mixed solution of BFE and 5wt% DCA is coated with a thickness of 25nm on the substrate on which ITO has been formed to form a hole injection layer, and then A hole transport layer with a thickness of 25 nm was formed on the hole injection layer using IDE320.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com