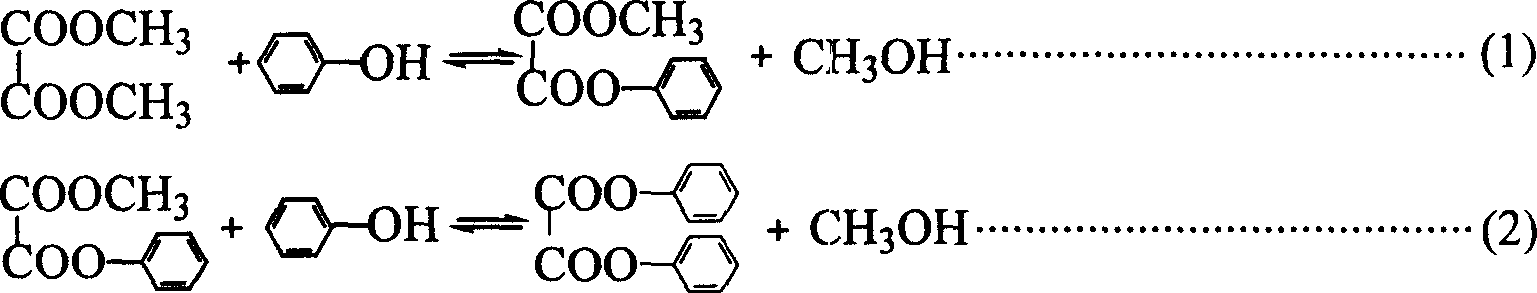

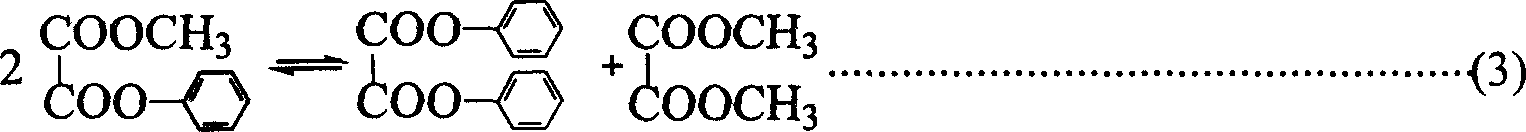

Preparation of loaded molybdenum oxide catalyst for synthesis of phenyloxalate by ester interchange process

A technology of phenyl oxalate and catalyst, which is applied in the field of supported molybdenum oxide catalyst and its preparation, can solve the problems such as the catalyst preparation method not mentioned, and achieve the goal of saving separation process and equipment, reducing production cost and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention is the implementation and investigation of molybdenum oxide supported catalyst for the preparation of phenol and dimethyl oxalate transesterification method for synthesizing phenyl oxalate by slurry impregnation method. Grind molybdenum trioxide into 200-mesh fine particles, dry in a drying oven at 120°C, and set aside. Weigh 1.278g of dried molybdenum trioxide and add 70ml of deionized water to form a mixed solution. Weigh 20 g of 80-mesh activated carbon carrier particles, place them in a rotary evaporator, and impregnate them with an impregnation solution at 95° C. for 8 hours. The impregnated catalyst was dried at a drying temperature of 120° C. for 6 hours; taken out to obtain a molybdenum oxide-supported catalyst with a molybdenum loading of 4 wt%.

[0022] Catalyst that the present invention makes is under heterogeneous catalyzed reaction condition with dimethyl oxalate and phenol as raw material to prepare methyl phenyl oxalate and dipheny...

Embodiment 2-4

[0024] Changing the Supported Molybdenum Trioxide Catalyst MoO 3 The load of molybdenum in / C is respectively 8%, 16%, 32%, and under the completely identical situation of other conditions and embodiment 1, carry out transesterification reaction, form embodiment 2-4 respectively, investigate reaction result.

[0025] Table 1: MoO 3 / C series catalyst preparation method and catalytic transesterification reaction results (weight percentage)

[0026] Molybdenum trioxide Deionization Impregnation Impregnation Drying

[0027] Molybdenum loaded DMO yield, %

[0028] Example Mass Water Volume Temperature Time Temperature

[0029] Amount, % Conversion %

[0030] g ml ℃ h ℃ MPO DPO

[0031] 1 4 1.28 70 90 8 120 49.5 40.6 8.7

[0032] 2 8 2.73 80 90 12 120 59.0 48.0 10.8

[0033] 3 16 6.32 90 95 24 120 64.3 54.2 9.7

[0034] 4 32 18.48 110 95 36 120 56.8 47.2 7.4

Embodiment 5-7

[0036] Switch to SiO2 2 Support, prepared MoO by slurry impregnation method 3 / SiO 2 Series of catalysts, supported molybdenum trioxide catalyst MoO 3 / SiO 2 The loads of molybdenum in the medium were 4%, 8%, and 16% respectively. Under the same conditions as in Example 1, the transesterification reaction was carried out to form Examples 5-7 respectively, and the reaction results were investigated.

[0037] Table 2: MoO 3 / SiO 2 Series catalyst preparation method and catalytic transesterification reaction results (weight percentage)

[0038] Molybdenum trioxide Deionization Impregnation Impregnation Drying

[0039] Molybdenum loaded DMO yield, %

[0040] Example Mass Water Volume Temperature Time Temperature

[0041] Amount, % Conversion %

[0042]g ml ℃ h ℃ MPO DPO

[0043] 5 4 1.28 80 80 12 140 46.1 38.1 6.8

[0044] 6 8 2.73 100 90 24 140 57.8 47.3 10.3

[0045] 7 16 6.32 120 95 36 140 54.6 46.0 8.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com