Static pressure hydrothermal and hydrolytic preparing technology for cuprous chloride crystal

A technology of cuprous chloride and hydrolysis method, applied in the direction of cupric chloride, cupric halide, etc., can solve the problems of polluting the environment, wasting raw materials, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

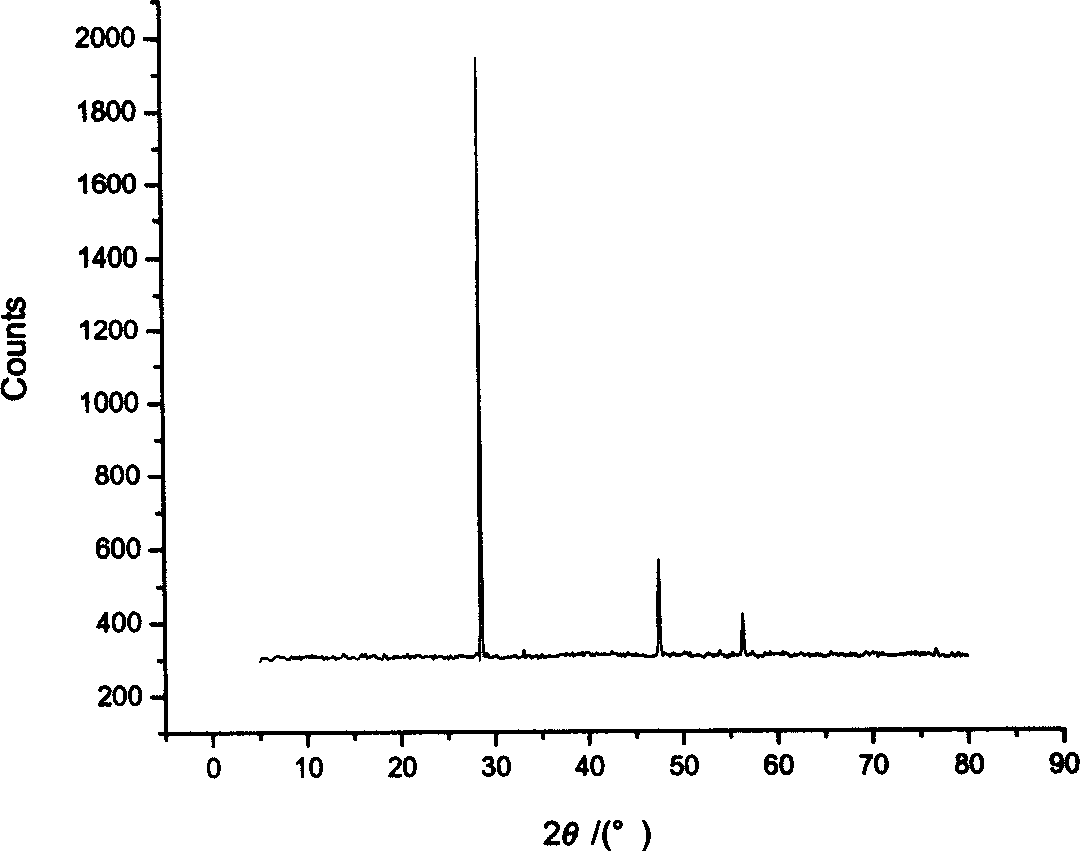

Image

Examples

Embodiment 1

[0020] Add a certain concentration of copper sulfate and sodium chloride mixed solution into the three-necked flask, then add excess red copper powder, use concentrated hydrochloric acid to adjust the acidity of the solution to 0.1mol / L, and connect the spherical condenser tube and exhaust gas absorption device to the middle of the flask , two dropping funnels are installed on both sides of the funnel, one for water and the other for concentrated hydrochloric acid. The flask is heated to make the material undergo a reduction reaction in boiling. During the reaction, pay attention to adding water to keep the liquid level basically unchanged. When the solution is beige and white cuprous chloride crystals are precipitated, slowly add concentrated hydrochloric acid to make the generated cuprous chloride crystals just completely generate [CuCl 2 ] - ion and dissolved, filtered while hot to remove excess copper powder; transfer the filtrate to a high-pressure reaction kettle with Fr...

Embodiment 2

[0022] Add a certain concentration of copper sulfate and sodium chloride mixed solution into the three-necked flask, then add excess red copper powder, adjust the acidity of the solution to 1mol / L with concentrated hydrochloric acid, connect the spherical condenser and tail gas absorption device in the middle of the flask, Two dropping funnels are installed on both sides of the funnel, one for water and the other for concentrated hydrochloric acid. The flask is heated to make the material undergo reduction reaction in boiling. During the reaction, pay attention to adding water to keep the liquid level basically unchanged. When the solution is beige and white cuprous chloride crystals are precipitated, slowly add concentrated hydrochloric acid to make the generated cuprous chloride crystals just completely generate [CuCl 2 ] - ion and dissolved, filtered while hot to remove excess copper powder; transfer the filtrate to a high-pressure reaction kettle with Freon lining, add an ...

Embodiment 3

[0024] Add a certain concentration of copper sulfate and sodium chloride mixed solution into the three-necked flask, then add excess red copper powder, adjust the acidity of the solution to 2mol / L with concentrated hydrochloric acid, connect the spherical condenser tube and tail gas absorption device in the middle of the flask, Two dropping funnels are installed on both sides of the funnel, one for water and the other for concentrated hydrochloric acid. The flask is heated to make the material undergo reduction reaction in boiling. During the reaction, pay attention to adding water to keep the liquid level basically unchanged. When the solution is beige and white cuprous chloride crystals are precipitated, slowly add concentrated hydrochloric acid to make the generated cuprous chloride crystals just completely generate [CuCl 2 ] - ions and dissolved, filtered while hot to remove excess copper powder; transfer the filtrate to a high-pressure reaction kettle with Freon lining, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com