Apparatus and process for purifying peach aldehyde by decompressing batch rectifying

A technology of peach aldehyde and rectification, which is applied in the field of separation and purification of synthetic peach aldehyde, can solve the problems such as purity only reaching 97wt%, destruction, etc., and achieve the effects of small liquid film thickness, simple operation process and high evaporation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

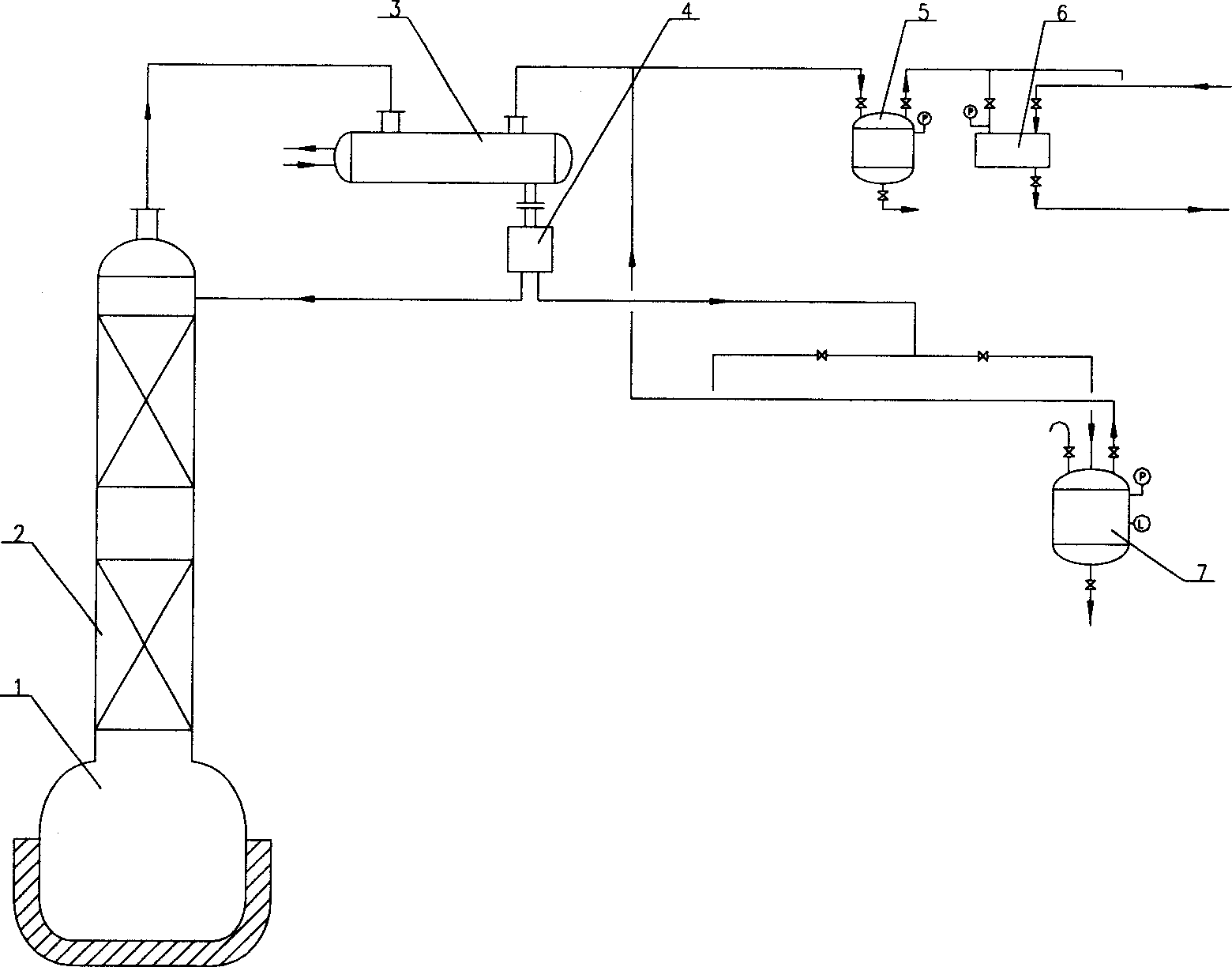

Image

Examples

Embodiment Construction

[0014] (1) add 150ml peach aldehyde crude product in the batch rectification tower (tower height 1 meter, built-in high-efficiency stainless steel wire mesh filler) still of 0.45 in aspect ratio, the content of active ingredient peach aldehyde is 66.77wt% in the crude product, wherein ratio The light impurity content of peach aldehyde is 17.90wt%, and the content of impurities heavier than peach aldehyde is 15.33wt%.

[0015] (2) Adjust the temperature of the voltage-regulating electric heating mantle to rise to 95°C at a constant speed. When liquid droplets appear on the top of the tower, perform a total reflux operation for about 40 minutes to enrich the light components at the top of the tower. At this time, the temperature at the top of the tower, The temperature at the bottom of the tower keeps rising.

[0016] (3) Then adjust the reflux ratio to 12, extract light impurities from the top of the tower, and operate for about 50 minutes. At this time, the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com