Liquid flow type capacitance pretreatment method for sea water desalination

A technology of pretreatment and capacitance method, which is applied in the direction of seawater treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problem of failing to meet FTC seawater desalination influent requirements, and cannot solve the problem of high hardness and high salinity of seawater, FTC Seawater desalination has high energy consumption and other issues, so as to reduce the total dissolved solids, improve the treatment effect and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

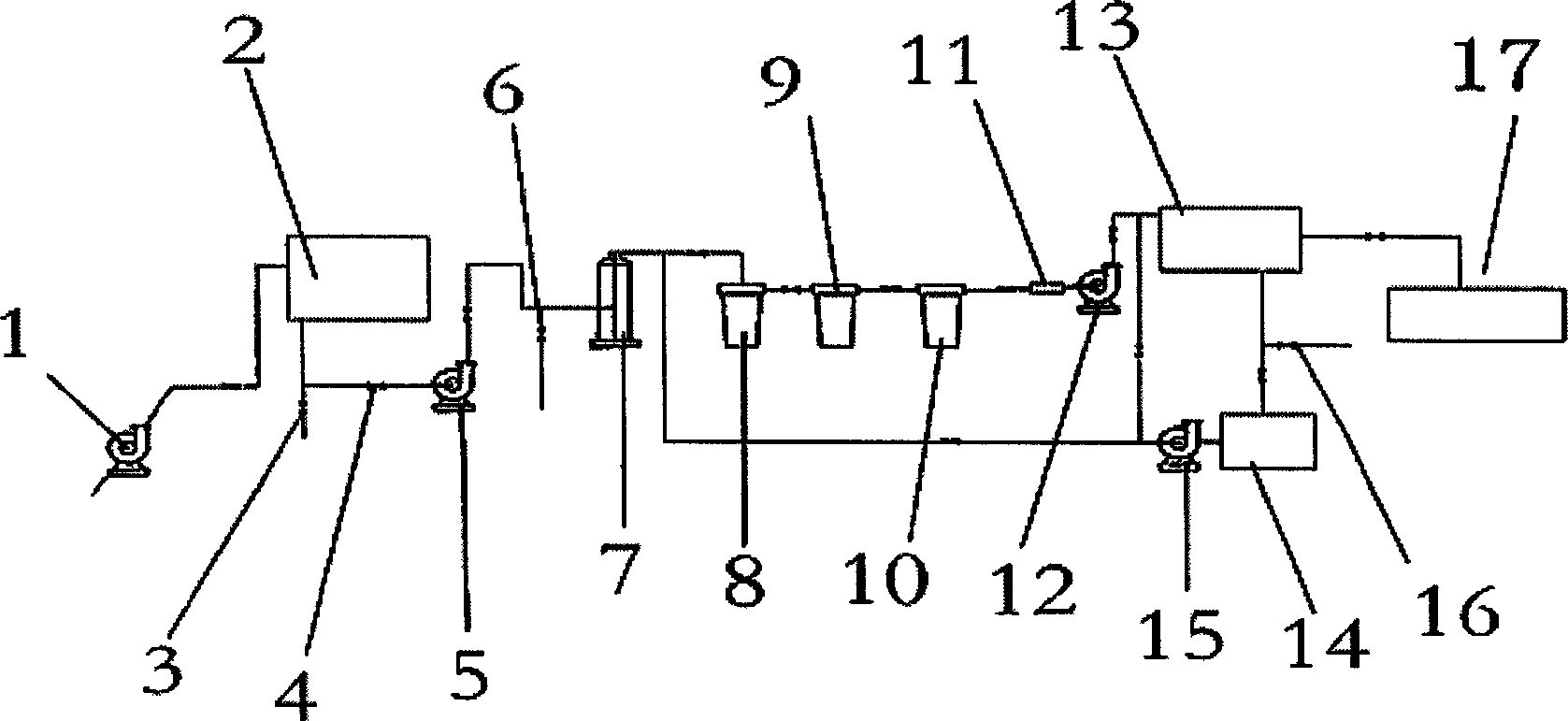

[0025] Example 1: see figure 1, using seawater with a concentration of 35000mg / L as the water source, the impurities in the seawater are filtered out through the multi-media filter unit 7, and then enter the activated carbon filter unit 8 to remove the odor in the seawater, natural and synthetic dissolved organic matter, micro-pollutants, etc., Then enter the fine filtration unit 9 to remove fine particles with a particle size of 1-5 μm, and at the same time further reduce the pollution index and prevent activated carbon particles from entering the downstream membrane module. Then pass through the ultrafiltration membrane unit 10 to remove pollutants on the order of microorganisms and bacteria, as well as pollutants on the order of harmful poisons, carcinogens, and viruses. At this time, the seawater has become clean brine after the above treatment, the turbidity of the effluent is NTU<0.1, suspended solids<1mg / L, total organic carbon content is 8-10mg / L, SDI<1, bacteria CFU / 1...

Embodiment 2

[0026] Embodiment 2: Using 20000mg / L seawater along the coast of China as the water source, after the same treatment process as the above-mentioned embodiment, the seawater has become clean brine, and then the booster pump enters the nanofiltration unit at 1.3Mpa and a temperature of 20°C Treatment 13 was used to remove 96% of hardness, 98% of sulfate, and 51% of chloride in water, and the TDS was reduced by 61%.

[0027] Through the examples, it can be known that the pretreatment method of the present invention can supply water to the seawater desalinator that meets the water quality requirements, and the water production rate can reach up to 70%, and the removal rate can reach more than 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com