Laser preparing method for Ta2O5 base transparent ceramics

A transparent ceramic, ta2o5 technology, applied in the field of preparation of Ta2O5-based transparent ceramics, can solve the problems of difficult control of the preparation process, high preparation cost, complicated preparation process, etc., achieve easy continuous production, reduce preparation cost, and strong process controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Will Ta 2 o 5 The powder is pre-fired at 1350°C for 4.8 hours, and then pressed into a billet; the laser is used as the direct heat source, and the temperature is 1250w / cm 2 The power density of the Ta 2 o 5 The ceramic billet is preheated; after the preheating is completed, the laser power density is adjusted to 5700w / cm 2 After sintering for 50s, the laser was turned off, and the sample was cooled to room temperature to obtain a transparent Ta 2 o 5 sample. The bulk density of the transparent sample is 8.396g / cm 3 , The relative density is 99.95%.

[0023] From figure 1 : Ta 2 o 5 It can be seen from the transparent ceramic renderings that the prepared Ta 2 o 5 Transparent ceramics have good light transmission.

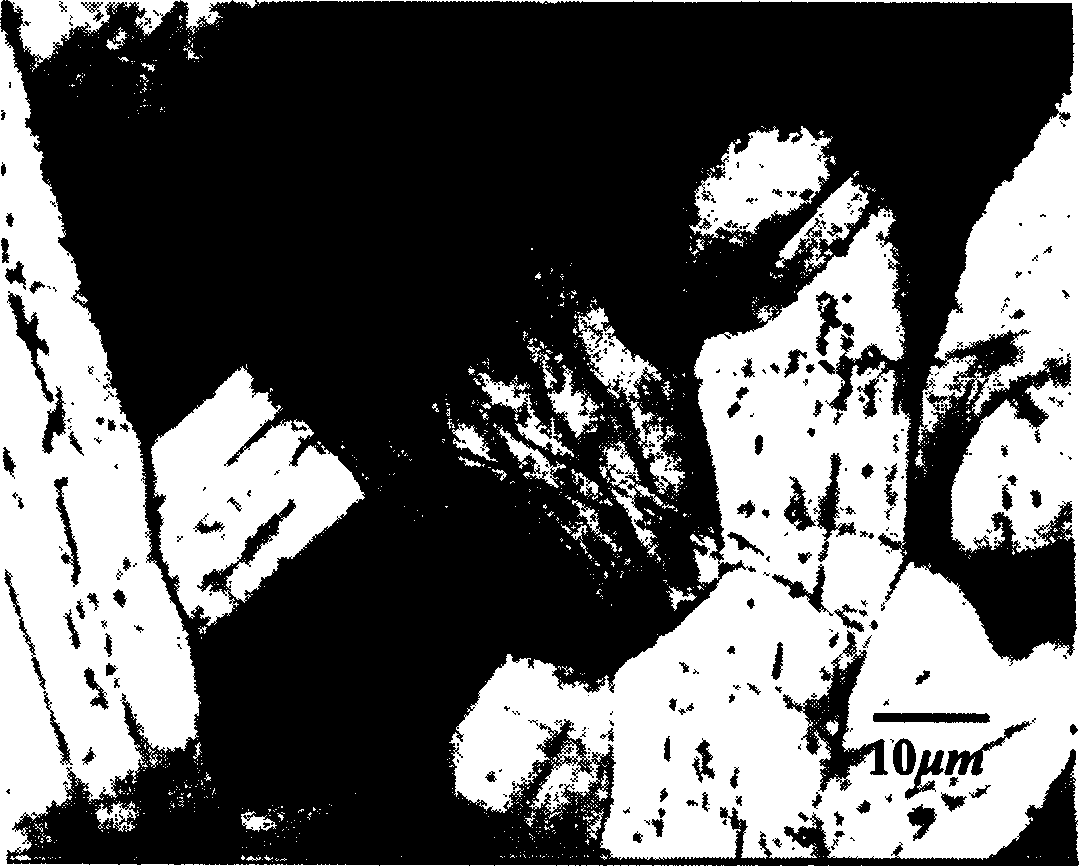

[0024] From figure 2 : Ta 2 o 5 It can be seen from the metallographic diagram of the transparent ceramic light transmission microscope that the prepared sample has extremely low porosity, relatively well-developed crystal grains, uniform siz...

Embodiment 2

[0026] Ta 2 o 5 and TiO 2 The powder is pre-fired at 1200°C for 5 hours, and then pressed into a billet; the laser is used as the direct heat source, and the temperature is 800w / cm 2 The power density of the (Ta 2 o 5 ) 0.92 (TiO 2 ) 0.08 The ceramic billet is preheated; after the preheating is completed, the laser power density is adjusted to 5200w / cm 2 After sintering for 30s, the laser was turned off, and the sample was cooled to room temperature to obtain a transparent (Ta 2 o 5 ) 0.92 (TiO 2 ) 0.08 ceramic samples. The bulk density of the transparent sample is 8.239g / cm 3 , the relative density is 98.08%.

[0027] From image 3 :( 2 o 5 ) 0.92 (TiO 2 ) 0.08 As can be seen from the transparent ceramic renderings, the prepared (Ta 2 o 5 ) 0.92 (TiO 2 ) 0.08 Transparent ceramics have good light transmission.

Embodiment 3

[0029] Ta 2 o 5 and TiO 2 The powder is pre-fired at 1250°C for 5.6 hours, and then pressed into a billet; the laser is used as the direct heat source, and the temperature is 1150w / cm 2 The power density of the (Ta 2 o 5 ) 0.92 (TiO 2 ) 0.08 The ceramic billet is preheated; after the preheating is completed, the laser power density is adjusted to 4800w / cm 2 After sintering for 40s, the laser was turned off, and the sample was cooled to room temperature to obtain a transparent (Ta 2 o 5 ) 0.92 (TiO 2 ) 0.08 ceramic samples. The bulk density of the transparent sample is 8.218g / cm 3 , the relative density is 97.83%.

[0030] Figure 4 :( 2 o 5 ) 0.92 (TiO 2 ) 0.08The characteristic peaks shown in the X-ray diffraction spectrum of transparent ceramics are sharp and there are no miscellaneous peaks, indicating that the prepared sample is pure in phase, free of impurities, and has a uniform single-phase structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com