Synthesis and purification method of medium chain triglycerides

A medium-carbon chain triglyceride and purification method technology, applied in the field of preparation of high-purity medium-carbon chain triglyceride, can solve the problems of long reaction time, volatile solvent, solvent residue, etc., and achieve good catalytic effect and thermal stability Good sex, not easy to lose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The synthesis of embodiment 1. medium carbon chain glyceride

[0015] The increase in temperature is conducive to the rapid generation of triglycerides, so the temperature is set at the best level of esterification rate, that is, the starting temperature is 140°C and the final temperature is 160°C. That is to say, for the central combination design of three factors, three levels, and two indicators, the three factors selected are: acid-alcohol ratio, time, and absolute pressure, and the indicators are: esterification rate and MCT selectivity.

[0016] Factor: X1——acid-alcohol ratio (W / W), 3.1-3.3;

[0017] X2——time (min), 75-105;

[0018] X3——absolute pressure (×10 4 Pa), 0.8-1.2;

[0019] Index: Y1 - Esterification rate

[0020] Y2—Selectivity of MCT

[0021] factor

[0022] The experimental scheme and experimental results are shown in Table 2.

[0023]

[0024] According to the response surface analysis method, the optimal c...

Embodiment 2

[0025] Embodiment 2. Physical purification of medium carbon chain triglycerides

[0026] Nitrogen is used as stripping steam, which has a very good deacidification effect on MCT, and the acid value can be reduced to below 1. The best operating conditions are: pressure 300Pa, temperature 170°C, distillation time 80min. After alkali refining, MCT with an acid value of 0.5 and a purity of up to 85% can be obtained.

Embodiment 3

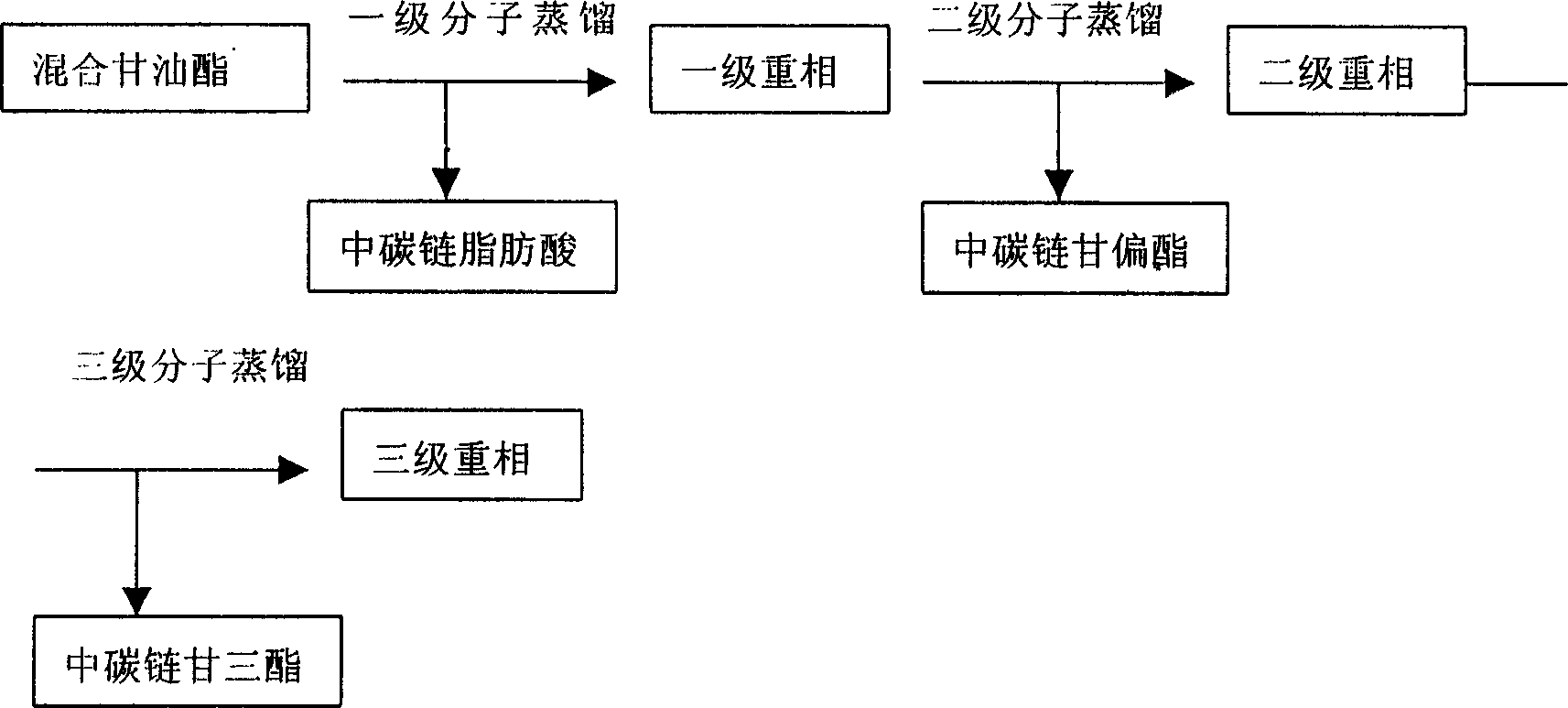

[0027] Embodiment 3. The three-stage molecular distillation purification of medium carbon chain triglyceride

[0028] Influence of Temperature of Primary Molecular Distillation on Acid Value and Yield of Heavy Phase

[0029] As the distillation temperature rises, the fatty acid molecules in the feed liquid gain energy and the molecular motion intensifies, which not only leads to the acceleration of molecular motion, but also increases the amount of fatty acid in the form of vapor, reduces the yield of heavy phase, and reduces the acid value, which is beneficial to Deacidification. But at the same time, the increase in temperature also accelerates the volatilization of monoglycerides and diglycerides in the oil, resulting in a decrease in the yield of glyceryl partial esters of medium carbonate. In order to better separate fatty acids and obtain more glycerin partial esters of medium carbonate, the flow rate is 1.2-1.6L / m 2h, the temperature is controlled at 110-115°C and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com