Process for preparing 2,2'-dichloro-hydrazobenzene

A technology of dichlorohydroazo and o-nitrochlorobenzene, which is applied in 2 fields, can solve the problems of catalyst separation and recovery and regeneration yield affecting production costs, precious metal catalysts are expensive, and labor-intensive, etc., to achieve recovery and mechanical application Convenience, low cost, and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

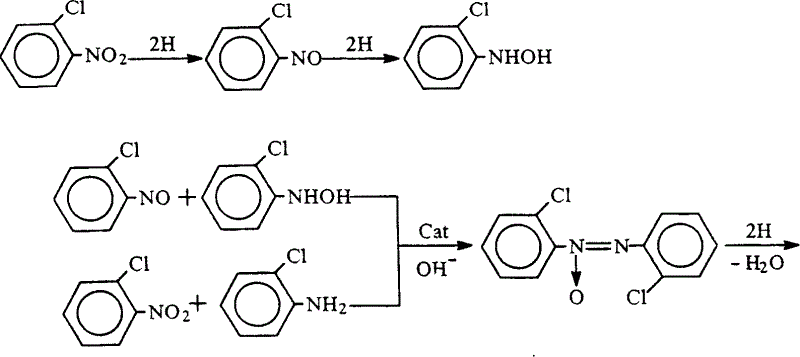

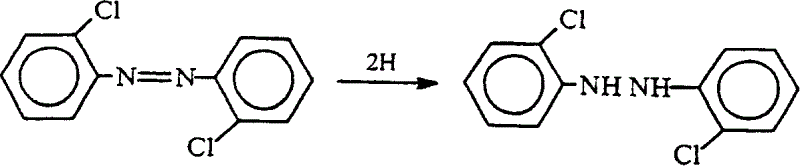

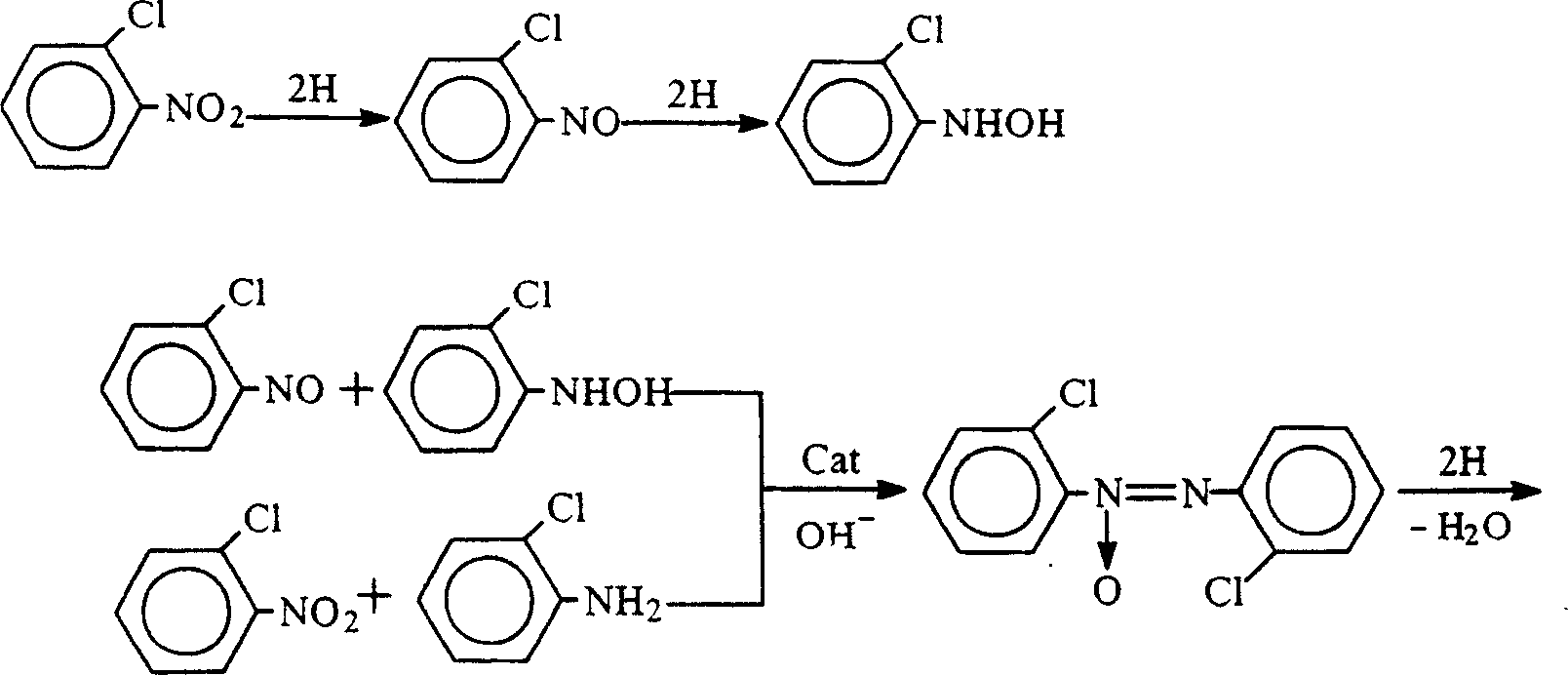

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of 2,2'-dichlorohydroazobenzene by batch hydrogenation reduction

[0018] In a 1-liter autoclave, add 120 grams of o-nitrochlorobenzene, 200 milliliters of toluene, 150-200 milliliters of pre-prepared methanol / sodium hydride solution (12 grams of solid alkali dissolved in 100 milliliters of methanol), 10 grams of nickel Catalyst, 0.5-1 gram of cocatalyst, 2 grams of dechlorination inhibitor ethanolamine. After the feeding is completed, the autoclave is closed, and the air is replaced with nitrogen and hydrogen respectively, and 0.6Mpa hydrogen is introduced, stirring and heating are started, and hydrogenation reduction reaction is carried out at 40-50°C.

[0019] In the initial stage, it is advisable to keep the hydrogen absorption rate at 0.05Mpa for every 0.05Mpa drop in hydrogen pressure. As time goes on, the hydrogen absorption rate will gradually slow down. It takes more than 30 minutes to drop by 0.05Mpa, and the reaction ends at this moment...

Embodiment 2

[0022] Example 2 Preparation of 2,2'-dichlorohydroazobenzene by continuous hydrogenation reduction in kettle

[0023] Three 1-liter high-pressure reactors and one 5-liter pressure receiving tank are connected in series, and the liquid material flows through the three reactors in sequence according to the liquid level difference, and finally reaches the receiving tank. The receiving tank discharges the material intermittently, but it does not affect the continuous input and output of the material, thus realizing the continuous hydrogenation process. Each reactor has a double-valve feeding port to add catalyst intermittently, and the balance pipe is used to balance the pressure between each reactor so that the material overflows.

[0024] To prepare the toluene solution of o-nitrochlorobenzene, add 600 grams of o-nitrochlorobenzene and 3 grams of promoters in every liter of toluene and stir evenly. Prepare a methanol solution of sodium hydroxide, add 120 grams of solid alkali t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com