Preparation of potassium lithium niobate nanometer powder using citric acid gelification method

A technology of potassium lithium niobate and nano powder, applied in chemical instruments and methods, niobium compounds, inorganic chemistry and other directions, can solve the problems of high calcination temperature, poor sintering activity of powder, high price, etc., to overcome the high calcination temperature , the effect of reducing environmental pollution and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

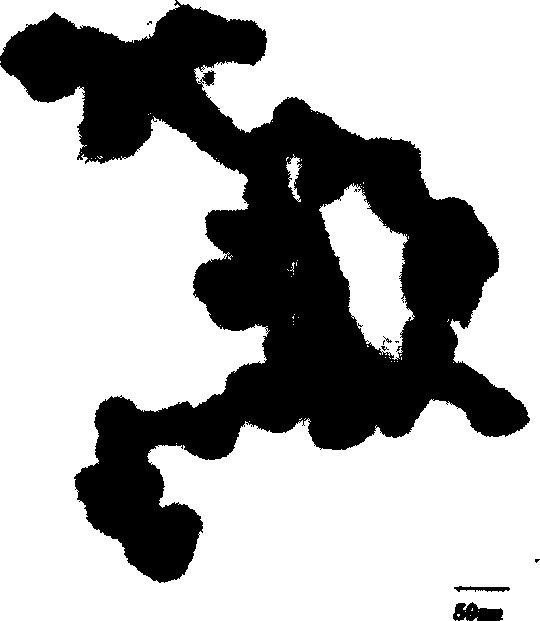

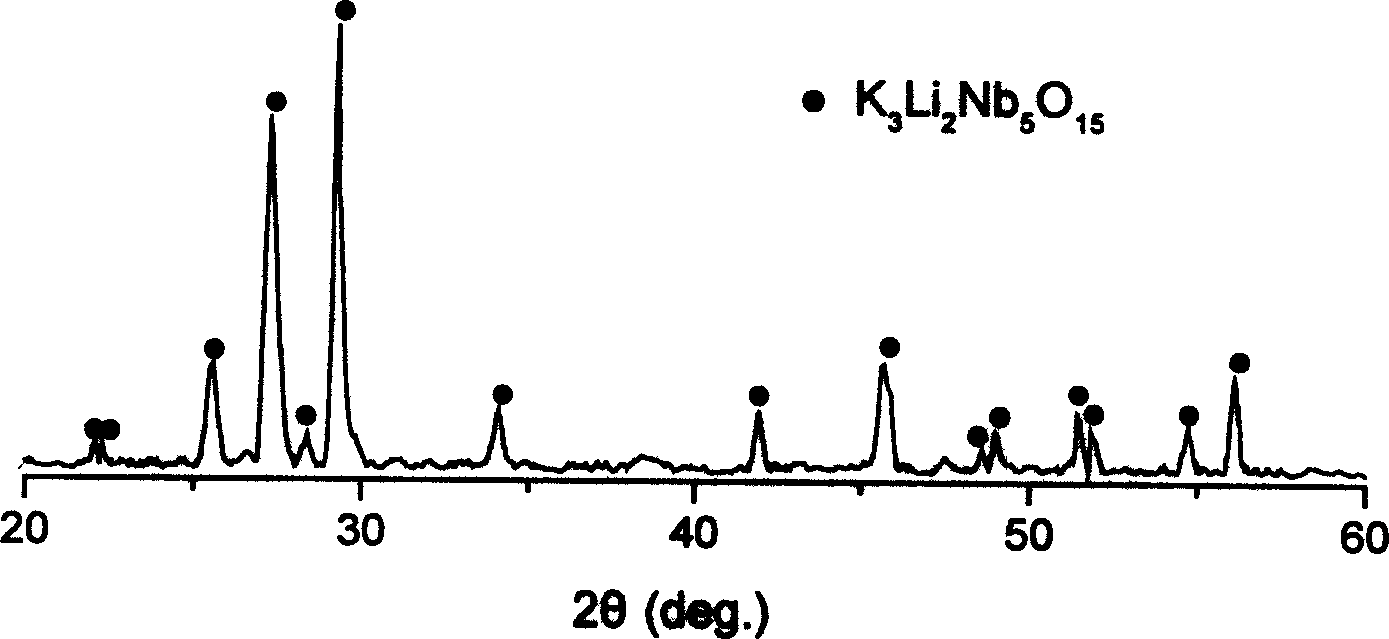

Image

Examples

specific Embodiment approach 1

[0005] Specific embodiment one: this embodiment is carried out according to the following steps: a, Nb 2 o 5 Dissolve in HF at 70-90°C, then add excess ammonium oxalate solution to it, after mixing thoroughly, add ammonia water dropwise to the solution to form white Nb(OH) 5 Precipitate, which is aged at 70-90°C for 10-14 hours, filtered and washed, dissolved in citric acid aqueous solution to form a light yellow Nb-citric acid solution; b, according to the molar ratio of Nb 5+ : Li + : K + =(5+x): (2-x): 3 ratio Lithium carbonate, Nb-citric acid solution and potassium carbonate are mixed, after fully stirring, add excess citric acid, make metal ion (Nb 5+ , Li + 、K + ) and citric acid in a molar ratio of 1:3, adjust the pH value of the solution to 6 to 7 with ammonia water; c, add ethylene glycol to the mixed solution, and stir evenly to form a potassium lithium niobate precursor solution; d, mix The solution was heated at 60-100°C for 20-30h to obtain a viscous gel-lik...

specific Embodiment approach 2

[0006] Specific embodiment two: this embodiment is carried out according to the following steps: a, Nb 2 o 5 Dissolve in HF at 80°C, then add excess ammonium oxalate solution to it, after mixing well, add ammonia water dropwise to the solution to form white Nb(OH) 5 Precipitate, the precipitate was aged at 80°C for 12 hours, filtered and washed, dissolved in citric acid aqueous solution to form a light yellow Nb-citric acid solution, and the solution was measured by inductively coupled plasma emission spectrometry (ICP) The concentration of metal Nb in the medium; b, get Nb-citric acid solution (containing Nb 5+ 0.5mol), the lithium carbonate of 0.1mol is added in the Nb-citric acid solution, stirring makes it fully dissolve, then the potassium carbonate of 0.15mol is added wherein, after fully stirring, add excessive citric acid, make metal ion (Nb 5+ , Li + 、K + ) and citric acid in a molar ratio of 1:3, the pH value of the solution is adjusted to 6-7 with ammonia water;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com