Method for preparing fixed yeast cell micro capsule

A technology of immobilizing yeast and microcapsules, which is applied in the direction of fixing on/in the organic carrier, so as to reduce the leakage of yeast cells, ensure the effective utilization rate, and increase the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

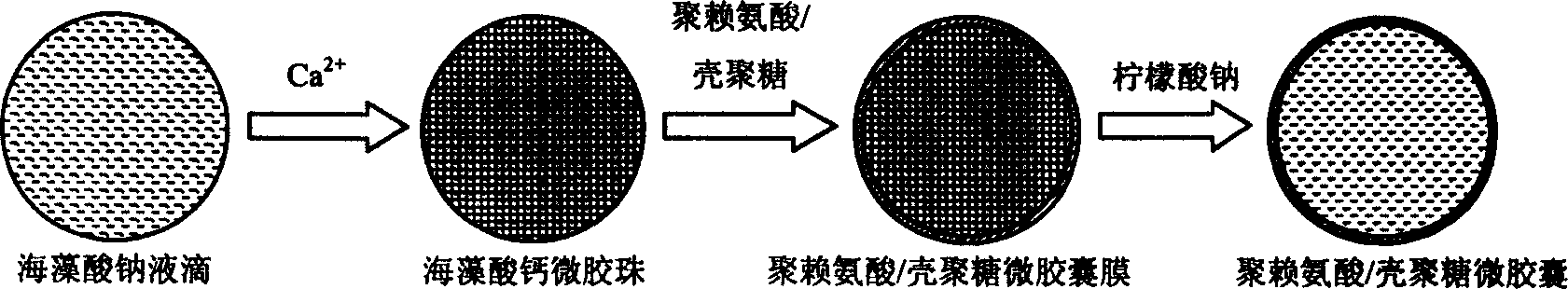

[0022] Example 1: Please refer to figure 1 , the suspension culture yeast GS115 in the logarithmic growth phase was centrifuged to collect the bacteria, and mixed evenly with 15g / L sodium alginate solution. Under the action of a high-voltage electric field of a high-power microcapsule preparation instrument, drop into 100mmol / L calcium chloride solution for gelation reaction for 30 minutes to prepare calcium alginate gel beads with a particle size of 300μm, and then mix with 0.5g / L The mixed solution of polylysine and 5g / L chitosan was film-forming reaction for 10 minutes, 55mmol / L sodium citrate solution was liquefied for 10 minutes after washing with normal saline for 3 times, and polylysine was prepared after washing with normal saline for 3 times / Chitosan microencapsulated yeast with a thickness of 65 μm. The whole preparation process is completed under physiological conditions, and the survival rate of yeast cells is maintained at 100% during the preparation process. ...

example 2

[0023] Example 2: After the prepared polylysine and chitosan solutions used to prepare microcapsule membranes were fully contacted with yeast cells for 30 minutes, the dilution plate method was used to measure its effect on the activity of yeast cells. The results showed that the same as the control group. Compared with the number of live yeast cells after contacting with polylysine and chitosan, the number of live yeast cells did not decrease, which confirmed that polylysine and chitosan solutions had no effect on the activity of yeast cells.

example 3

[0024] Example 3: Place the prepared sodium alginate-polylysine / chitosan and calcium alginate microgel beads containing yeast cells in the YPD culture medium, culture in a shaker flask, 28°C, 180rpm, after 24 hours of cultivation (see figure 2 a and figure 2 b), Calculate the yeast cell leakage rate. The results showed that the leakage rate of cells in the sodium alginate-polylysine / chitosan microcapsule group was more than 3 times lower than that in the calcium alginate microgel beads group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com