Method for preparing fixed yeast cell micro capsule

A technology for immobilizing yeast and yeast cells, which is applied in the field of microcapsule preparation to achieve the effects of reducing leakage, uniform distribution, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

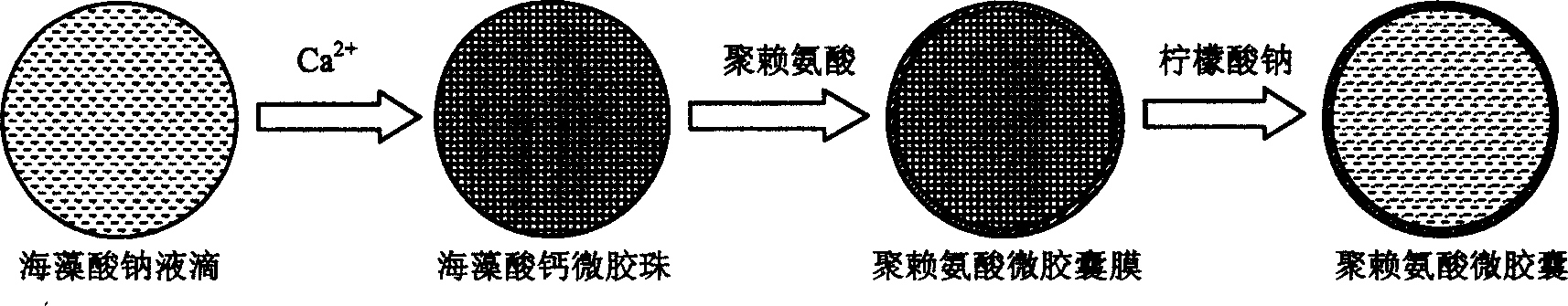

[0022] Example 1: please refer to the preparation process of the present invention figure 1 . The yeast GS115 in the logarithmic growth phase of the suspension culture was centrifuged to collect the bacteria, and mixed evenly with 15g / L sodium alginate solution. Under the action of a high-voltage electric field of a high-power microcapsule preparation instrument, drop into 100mmol / L calcium chloride solution for gelation reaction for 30 minutes to prepare calcium alginate gel beads with a particle size of 300μm, and then mix with 0.5g / L Polylysine solution film-forming reaction for 10 minutes, 55mmol / L sodium citrate solution was liquefied for 10 minutes after washing with normal saline for 3 times, and polylysine microencapsulated yeast was prepared after washing with normal saline for 3 times. 25 μm. The whole preparation process is completed under physiological conditions, and the survival rate of yeast cells is maintained at 100% during the preparation process.

example 2

[0023] Example 2: Put the prepared sodium alginate-polylysine microcapsules and calcium alginate microgel beads containing yeast cells in the YPD culture medium, culture in a shaker flask, 28°C, 180rpm, after culturing for 24 hours, calculate Yeast Cell Leakage Rate. The results showed that the cell leakage rate of the polylysine microcapsule group was more than 3 times lower than that of the calcium alginate microgel bead group.

example 3

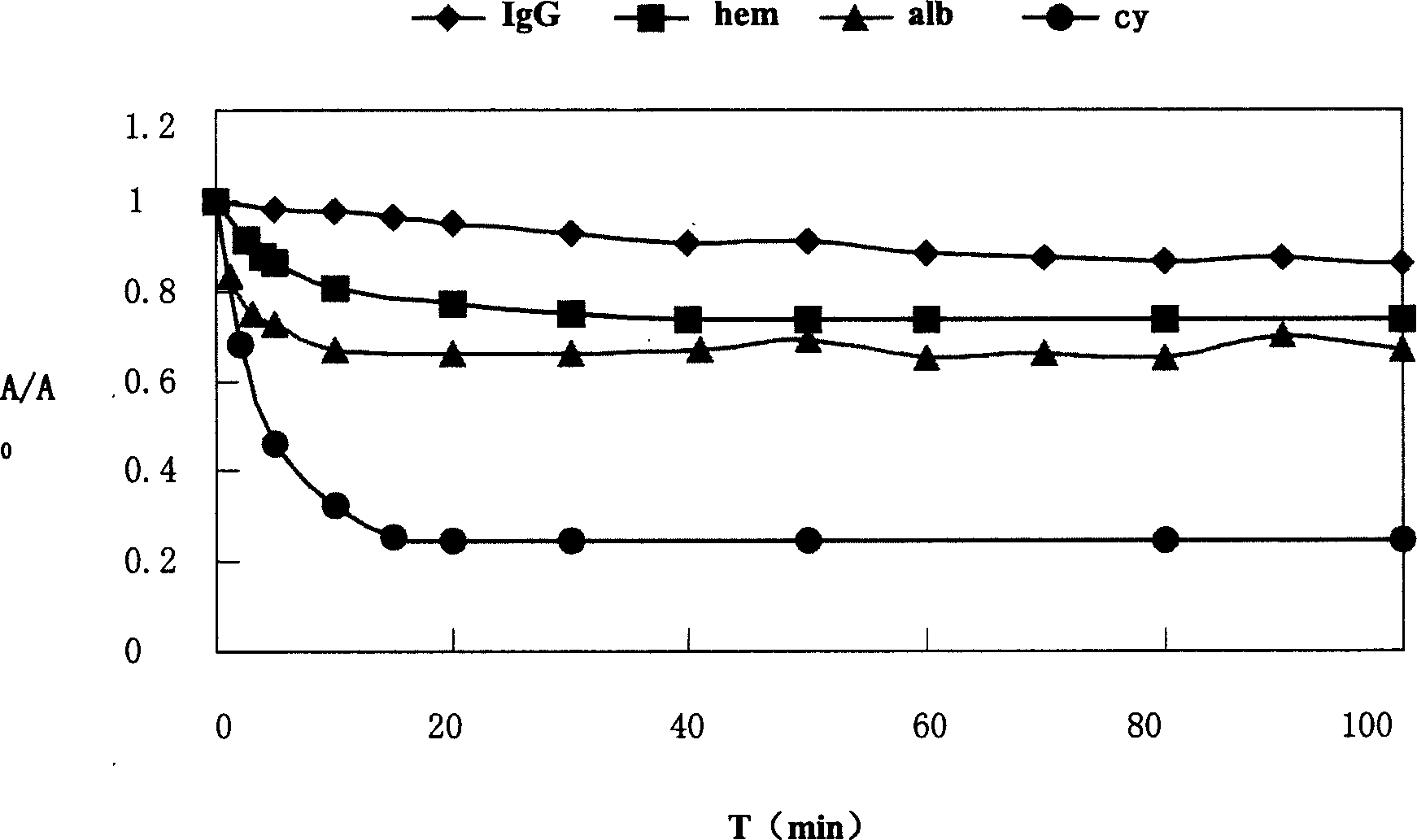

[0024] Example 3: figure 2 The diffusion curves of proteins with different molecular weights in sodium alginate-polylysine microcapsules are given. It can be judged from the figure that molecules below 10,000 Da can freely diffuse in sodium alginate-polylysine microcapsules. It does not affect the supply of nutrients and the discharge of metabolites of the yeast in the capsule.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com