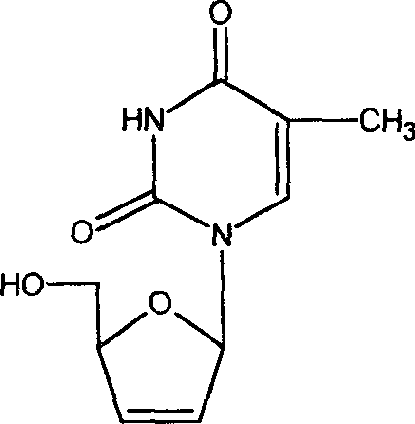

Stavudine sustained release tablet and its preparing process

A technology for stavudine and sustained-release tablets, which is applied in antiviral agents, pharmaceutical formulations, medical preparations containing active ingredients, etc. The probability of release” and the effect of improving drug safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Tablet core prescription Raw material Feeding amount Weight ratio

[0028] Stavudine 50g 1

[0029]

[0030] Makes 1000 pieces

[0031] 2. Tablet core preparation process

[0032] (1) Crush stavudine and pass through a 100-mesh sieve. Lactose, microcrystalline cellulose, magnesium stearate, and hypromellose are directly passed through an 80-mesh sieve for later use.

[0033] (2) The starch is made into 4% starch slurry for subsequent use.

[0034] (3) Weigh the prescribed amount of stavudine, lactose, and microcrystalline cellulose, and place them in a fluidized granulator. Turn on the fan to make the material in a state suitable for fluidization, and spray starch slurry into it for fluidization granulation.

[0035] (4) Add the prescribed amount of hypromellose and magnesium stearate to the dry granules, sieve through a 20-mesh sieve, and compress into tablets.

[0036] (5) After passing the inspection of the ta...

Embodiment 2

[0048] 1. Tablet core prescription Raw material Feeding amount Weight ratio

[0049] Stavudine 50g 1

[0050]

[0051] Makes 1000 pieces

[0052]2. Tablet core preparation process: the specific steps are as in 2 in Example 1.

[0053] 3. Coating prescription

[0054] Raw material Feed amount Weight ratio

[0055] Hypromellose 4.7g 1

[0056] Ethylcellulose 8.46g 1.80

[0057] Dibutyl sebacate 1.64g 0.35

[0058] 85% ethanol 176g 37.4

[0059] 4. Coating process: the specific steps are as in 4 in Example 1.

Embodiment 3

[0061] 1. Tablet core prescription Raw material Feeding amount Weight ratio

[0062] Stavudine 50g 1

[0063]

[0064] Makes 1000 pieces

[0065] 2. Tablet core preparation process

[0066] The specific steps are as in 2 in Example 1.

[0067] 3. Coating prescription

[0068] Raw material Feed amount Weight ratio

[0069] Hypromellose 4.7g 1

[0070] Ethylcellulose 10.34g 2.2

[0071] Dibutyl sebacate 1.88g 0.4

[0072] 85% ethanol 188g 40

[0073] 4. Coating process

[0074] The specific steps are as in 4 in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com