Recovery and molding process for phenol-formaldehyde resin composite waste

A technology of phenolic resin and molding process, which is applied in the field of recycling and reuse of leftover materials of automotive interior parts, can solve the problems of single solution for phenolic resin recycling, specificity of phenolic resin products, waste of available resources, etc. Minor pollution, convenient source, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

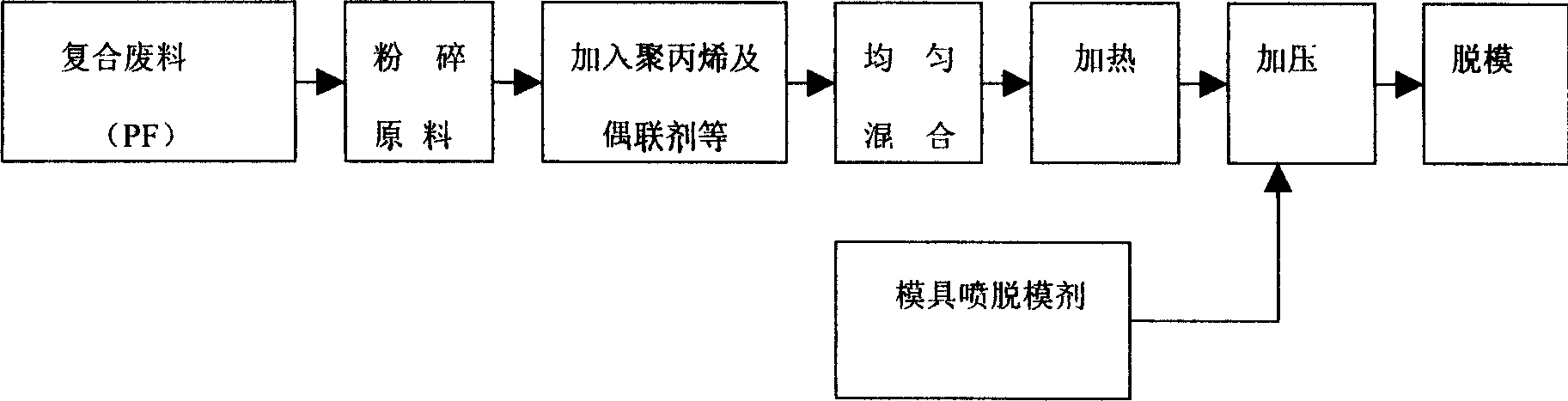

Image

Examples

Embodiment 1

[0017] Phenolic resin composite waste is a multi-layer laminated composite material, which contains impurities such as glass fiber and surface cloth. It is very difficult to separate these substances from each other. Fibers and resins in thermosetting plastic wastes can be used as fillers when they are recycled and reused in thermoplastics. They are highly recyclable and are not easy to cause secondary pollution. Therefore, in the embodiment of the present invention, the punched edge phenolic resin of the automotive interior parts is used. Resin composite waste is: 28% by weight. The phenolic resin composite waste is pulverized into a diameter of 1 mm and added to the heating mixer in the form of filler, then 46% by weight of pure polypropylene, a thermoplastic material, and a coupling agent for silane coupling are added. Agent KH-550, the chemical name is: -glycidyl etheroxypropyl trimethoxysilane: 12% by weight, ethylene bisstearyl EBS lubricating aid: 8% by weight, uniformly...

Embodiment 2

[0020] In the embodiment of the present invention, the phenolic resin punching edge composite waste of automobile interior parts is taken as: 36.5.5% by weight, and the polyurethane composite waste punching edge length is 1.5mm sheet and is added in the mixer in the form of filler, and then added pure 40.5% by weight of polypropylene, silane coupling agent KH-550: 11% by weight, ethylene bis-stearyl EBS lubricating aid: 6.5% by weight are uniformly mixed as a mixture; then the mixture is placed on the heating Heating in the container, the heating temperature is: 190°C, keep warm for 9.5 minutes until the mixture enters the molten state, first put glass fiber cloth in the mold: 5.5% by weight (according to the strength of the product, the glass fiber cloth can be placed in two layers ), and then move the molten mixture into the mold for molding, and the transfer time is controlled at 60s. Before material transfer, use methyl silicone oil release agent to evenly distribute in th...

Embodiment 3

[0022] In the embodiment of the present invention, the phenolic resin punching edge composite waste of automobile interior parts is taken as: 45% by weight, and the polyurethane composite waste is pulverized into a diameter of 2mm particles and added to the mixer in the form of filler, and then pure polymer is added in the mixer. Propylene 35% by weight, silane coupling agent KH-550: 10% by weight and ethylene bis stearyl EBS lubricating aid: 5% by weight, uniformly mixed as a mixture; then the above mixture is heated, Heating temperature: 195°C, keep warm for 10 minutes until the mixture enters the molten state, first put glass fiber cloth: 5% by weight in the mold, then move the molten mixture into the mold for molding, and the material transfer time is controlled at 70s. Before material transfer, use methyl silicone oil release agent to evenly distribute in the mold. The molten mixture is held in the mold for 5 minutes, the mold pressure is 1.6MPa, the cooling temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com