Method for online test of wafer metal interconnection line reliability

A technology of metal interconnection and online testing, applied in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., can solve the problem of complex detection process, affecting IC process yield, and inability to detect insulating dielectric materials on-line Layer reliability and other issues, to achieve the effect of rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

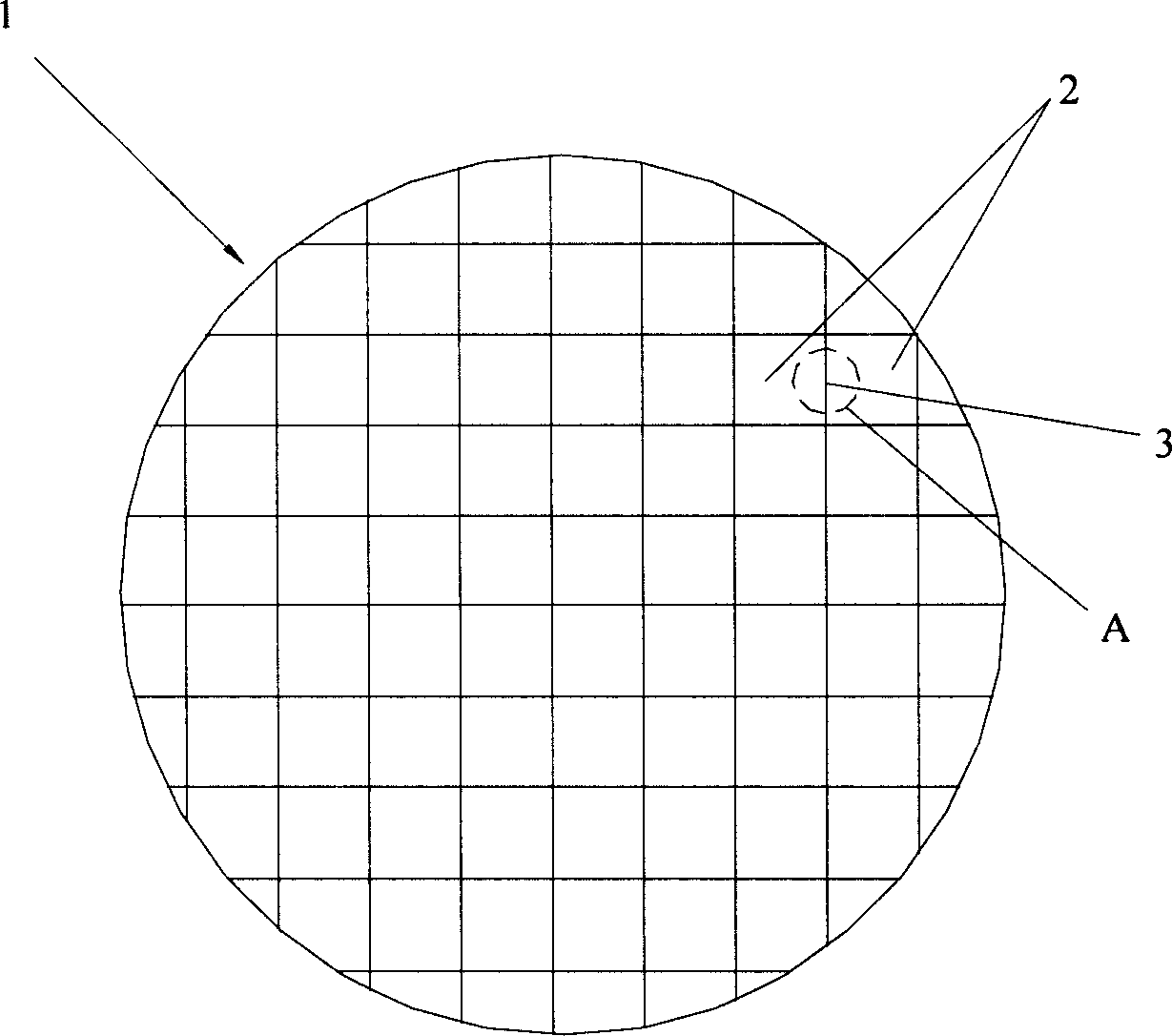

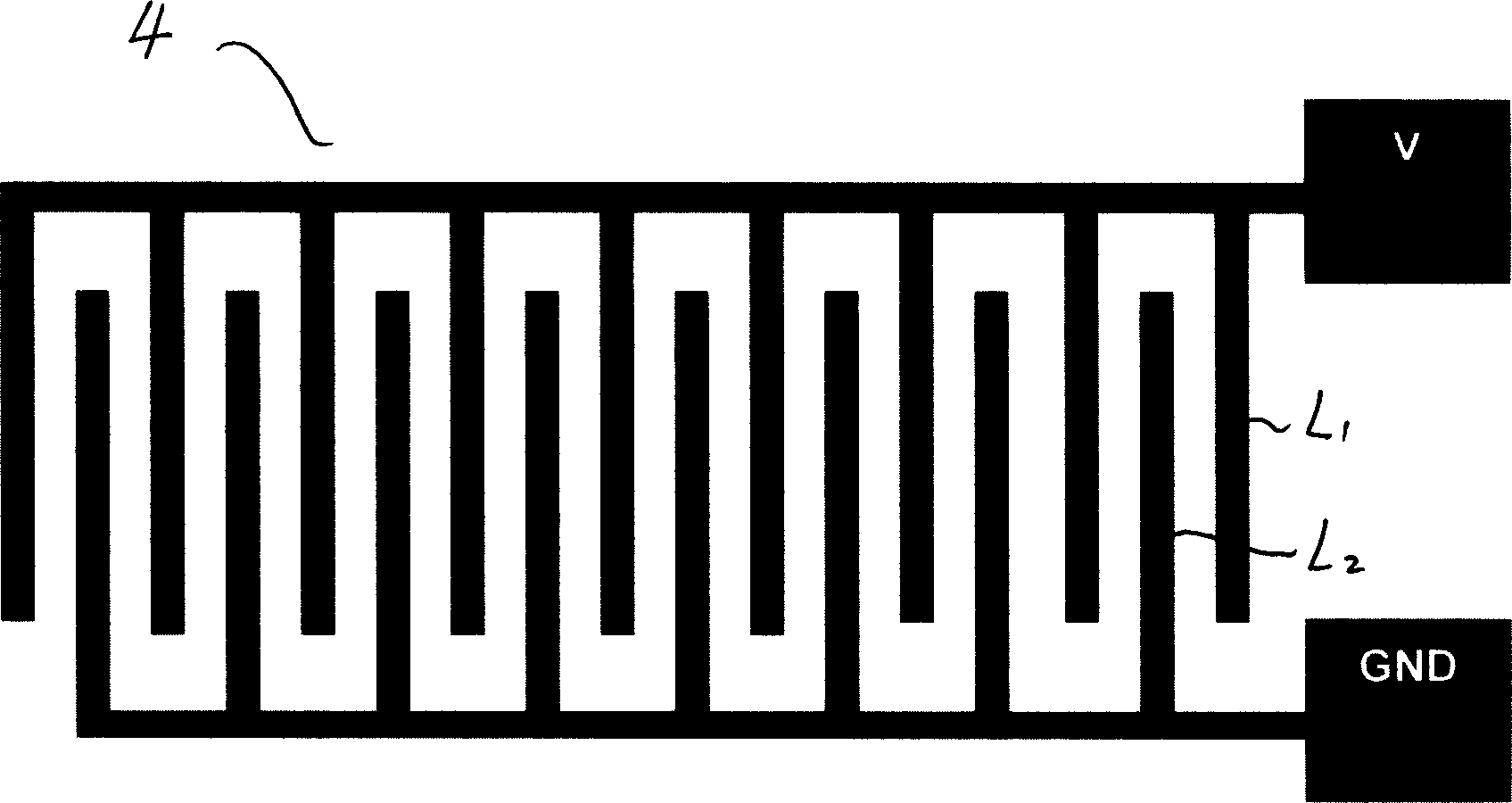

[0013] like figure 1 , figure 2 As shown, the present invention provides a method for on-line reliability testing of metal interconnects in a wafer. The method is to use the comb-shaped circuit of the test circuit 4 on the scribe line 3 between the main circuits (Circuit) 2 on the wafer 1 to apply a test voltage (Voltage), and measure Connection l in comb circuit 1 with connection l 2 Leakage Current and gradually increase the test voltage (Voltage), if the measured leakage current is small and its magnitude remains basically unchanged with the increase of the test voltage (the measured leakage current is in a small range) , indicating that the reliability of the wafer metal interconnects is good.

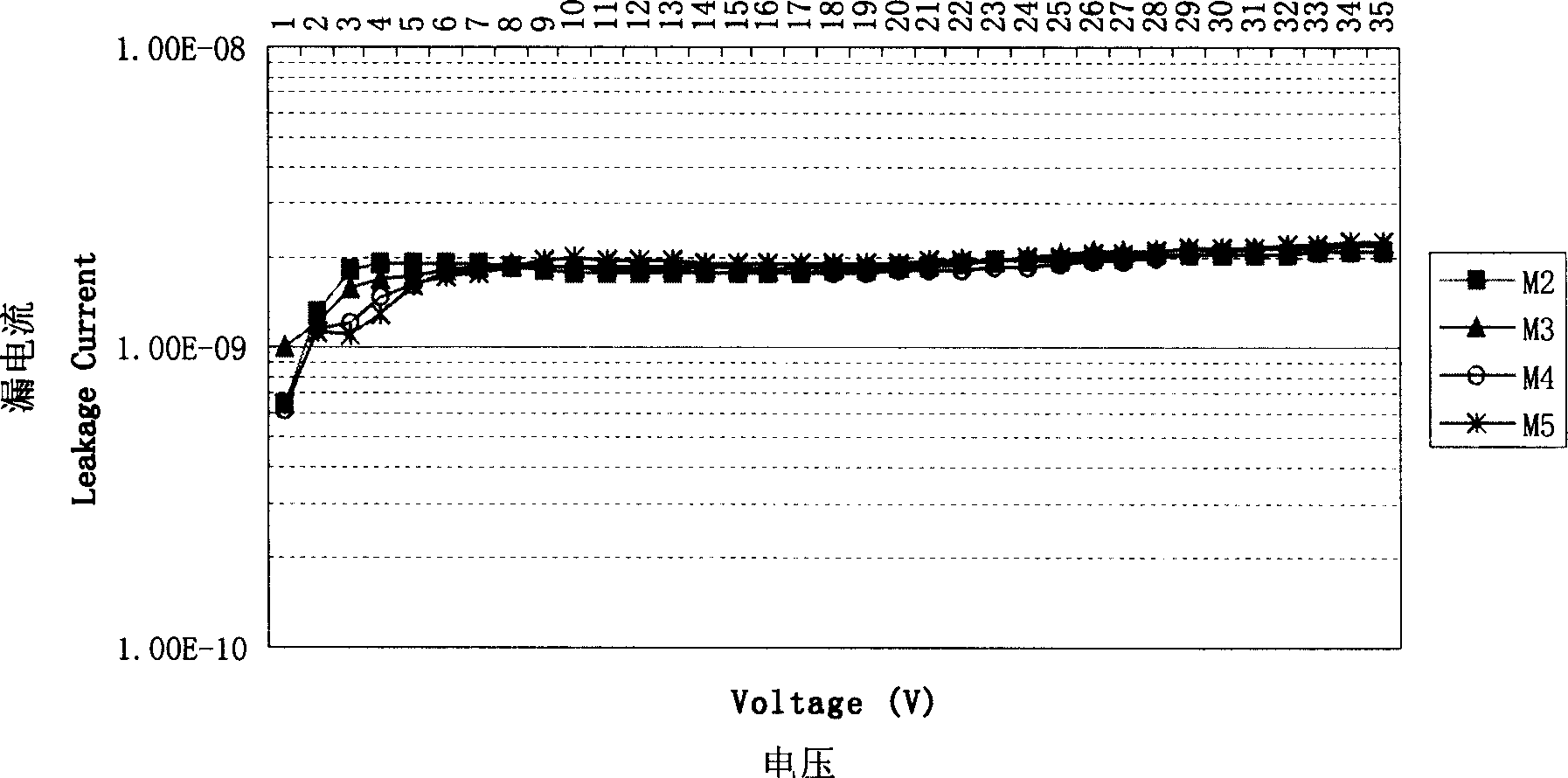

[0014] see image 3 , which shows a schematic diagram of the electrical test results of a 5-layer Cu metal interconnection of a wafer. As shown in the figure, the comb-shaped circuit of the test circuit applies a test voltage (Voltage), which increases by 1v each time, from 0v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com