Fire-retardant silicon rubber and its preparation method

A technology of silicone rubber and hydrogen-containing silicon, applied in the rubber field, can solve problems such as damage to the performance of silicone rubber, environmental hazards, and difficulty in vulcanization, and achieve the effects of improving flame retardancy, reducing dosage, and improving tear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

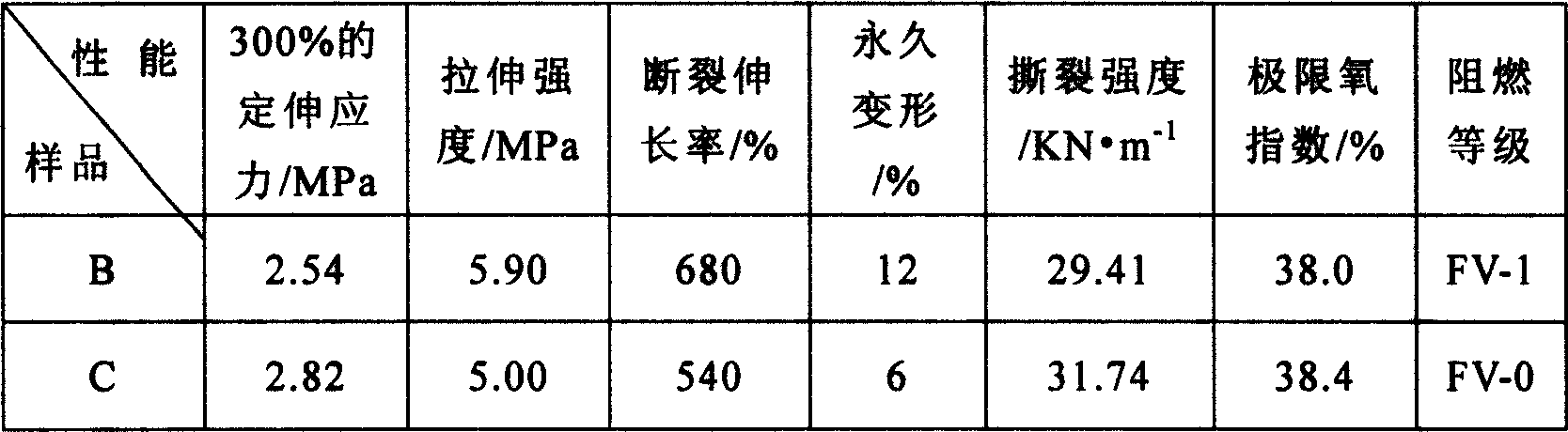

[0034] 96 parts by weight (phr) of methyl vinyl silicone rubber with a vinyl content of 0.3 mol% (the average degree of polymerization is 6500) and 4 phr of methyl vinyl silicone rubber with a vinyl content of 0.06 mol% (the average degree of polymerization is 5100 ) mixed evenly on the open mill, and then sequentially added 0.6phr hydrogen-containing silicone oil, 6phr hydroxyl silicone oil and 40phr specific surface area of 380m 2 / g of fumed silica, mixed evenly, and made into rubber compound A. Then add 45phr aluminum hydroxide and 15phr magnesium hydroxide to compound A, knead evenly, then heat treat at 150°C for 2 hours, cool to room temperature and carry out secondary re-milling, then add 2phr vulcanizing agent 2,5 -Dimethyl-2,5-di-tert-butylperoxyhexane, after mixing uniformly to obtain rubber compound B. Add 20 ppm of chloroplatinic acid to the rubber compound B to obtain the rubber compound C. Vulcanize compound B and compound C on a flat vulcanizing machine at 1...

Embodiment 2

[0039] The chloroplatinic acid used in the compound C in Example 1 was changed to 2.5 phr polytetrafluoroethylene powder to obtain sample D, and the results are shown in Table 2. It can be seen that adding polytetrafluoroethylene to silicone rubber can improve the flame retardancy and mechanical properties of silicone rubber.

[0040] Table 2 Effect of PTFE on properties of flame retardant silicone rubber

[0041]

Embodiment 3

[0043] According to the recipe and process in Example 1, by changing the consumption of chloroplatinic acid, the results are shown in Tables 3 and 4. It can be seen that with the increase of the amount of chloroplatinic acid, although the oxygen index of silicone rubber does not change much, the flame retardancy level gradually increases, and the tear strength of silicone rubber also increases. Considering the cost and performance of silicone rubber comprehensively, the optimal dosage of chloroplatinic acid is 20ppm (based on the amount of platinum).

[0044]Table 3 Effect of the amount of chloroplatinic acid on the flame retardant properties of silicone rubber

[0045] Dosage of chloroplatinic acid First combustion Second combustion Limiting oxygen index

[0046] Flammability rating

[0047] (ppm) Time (s) Time (s) (%)

[0048] 0 8 38 FV-1 38.0

[0049] 5 7 32 FV-1 38.1

[0050] 10 5 30 FV-1 38.2

[0051] 15 4 24 FV-0 38.2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com