Optical image functional membrane

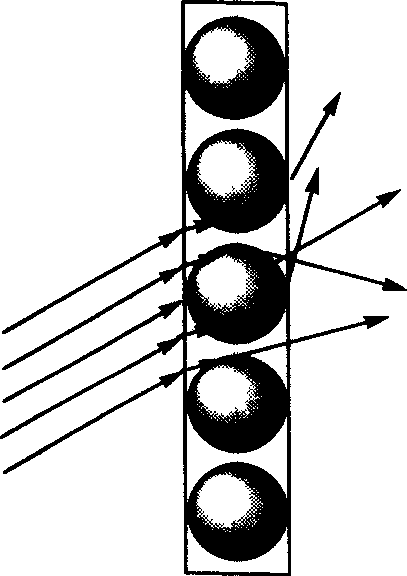

A functional film and optical imaging technology, which is applied in optics, image communication, image reproducer using projection device, etc., can solve problems such as uneven brightness of subtitle screen, affect the quality of audience, and unclear image, so as to curb bright spots effect, high gain, uniform optical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 95% polyvinyl alcohol is heated and dissolved in hot water and cooled to room temperature. Then sequentially add sodium dodecylsulfonate 1%, 100nm TiO 2 2% of nanoparticles, 1% of ammonium persulfate, and 1% of benzophenone are effectively stirred and heated to obtain uniformly dispersed thick liquid. Then apply to glass. Evaporate the solvent by vacuum drying, and vacuum dry at 60°C for 10 hours to obtain TiO 2 Ultrastructured polyvinyl alcohol films dispersed with nanoparticles. The resulting film was treated with UV light for 10 minutes to improve the optical and mechanical properties of the film. The MT830G front projector produced by NEC Corporation of Japan was used for rear projection imaging, and the CA-100CRT color analyzer was used for detection, showing good performance. Among them, the brightness is more than 1.5 times that of the same commercial rear projector, no color drift, the contrast ratio of light and dark is more than 150:1, the difference in br...

Embodiment 2

[0027]Polystyrene 65% was dissolved in chloroform / toluene, then 10nm iron oxide nanoparticles 10%, ammonium persulfate 1%, benzophenone 1%, phthalate 20%, azobisisobutyl Nitrile 3%, a homogeneously dispersed solution was obtained. The resulting solution was then sprayed onto a quartz plate. The solvent was evaporated by vacuum drying, and vacuum drying was performed at 40° C. for 10 hours to obtain a polystyrene film with ultrafine structure dispersed iron oxide nanoparticles. The resulting film was treated with UV light for 1 min to improve the optical and mechanical properties of the film. The MT830G front projector produced by NEC Corporation of Japan was used for rear projection imaging, and the CA-100CRT color analyzer was used for detection, showing good performance. Among them, the brightness is close to the same commercial rear projectors, with slight color drift, the contrast ratio of light and dark is more than 100:1, the brightness difference between the center an...

Embodiment 3

[0029] Polyethylene 92% was dissolved in toluene / THF, then 200nm Al was added sequentially 2 o 3 1% of nanoparticles, 1% of benzophenone, 5% of phthalate, 1% of azobisisobutyronitrile, and 1% of sodium dodecylsulfonate to obtain a homogeneously dispersed solution. The resulting solutions were then sprayed directly onto plastic films, respectively. Naturally dry and evaporate the solvent to obtain Al 2 o 3 Ultrastructured polyethylene films dispersed with nanoparticles. The resulting film was treated with UV light for 0.5 min to improve the optical and mechanical properties of the film, showing good performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com